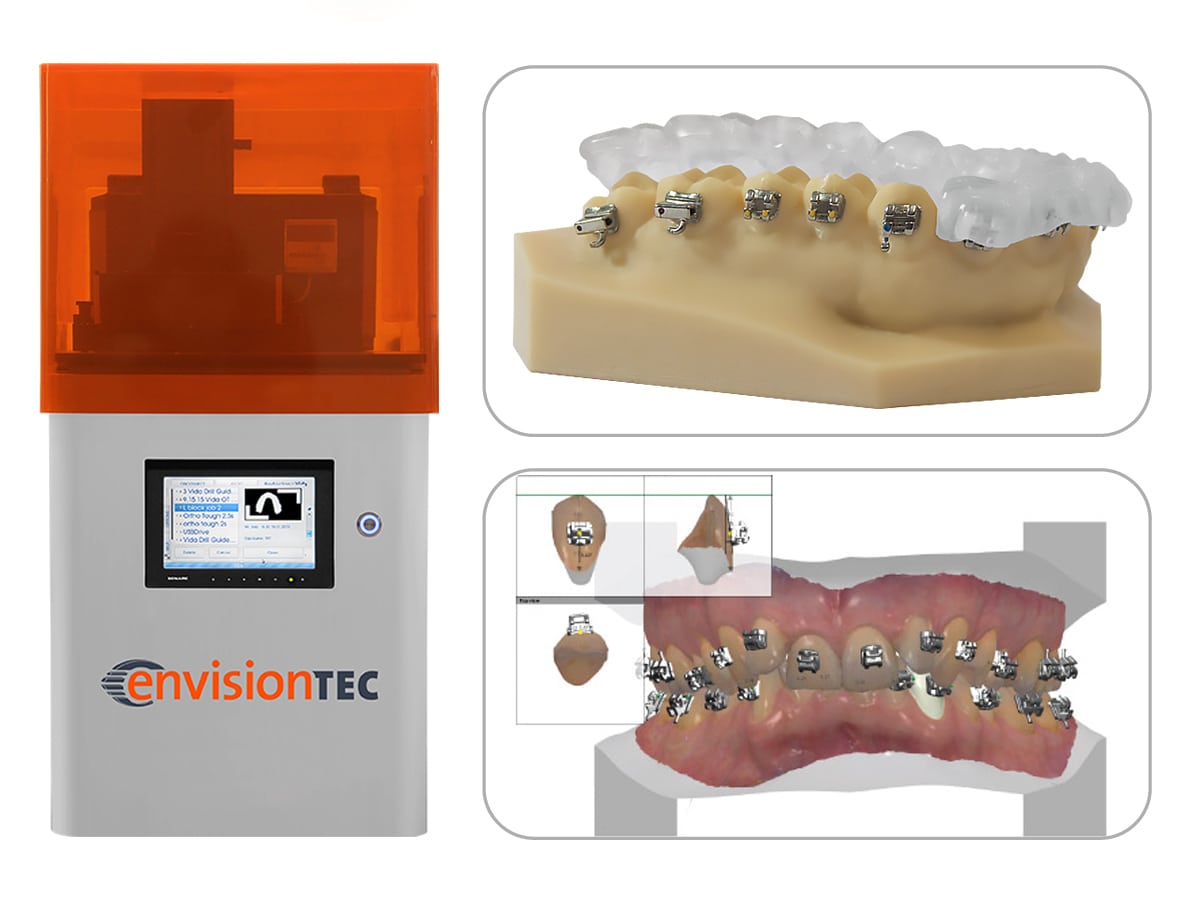

EnvisionTEC Previews New Material for 3D Printing Indirect Bonding Trays at World’s Largest Dental Show

• New E-IDB material joins industry-leading dental library for production of dental and orthodontic models, castables, appliances and restorations

• Trusted, accurate EnvisionTEC Vida 3D printer line for dental industry expands with high-speed cDLM model

• New partnership with 3Shape, whose 3Shape Trios scanner and Ortho Analyzer software work hand-in-hand with Vida for tray production

DEARBORN, Mich., March 20, 2017 — EnvisionTEC, a leading global manufacturer of desktop and full-production 3D printers and materials for the dental industry, this week previews a new dental material for 3D printing indirect bonding trays at IDS, the world’s largest dental show in Cologne, Germany.

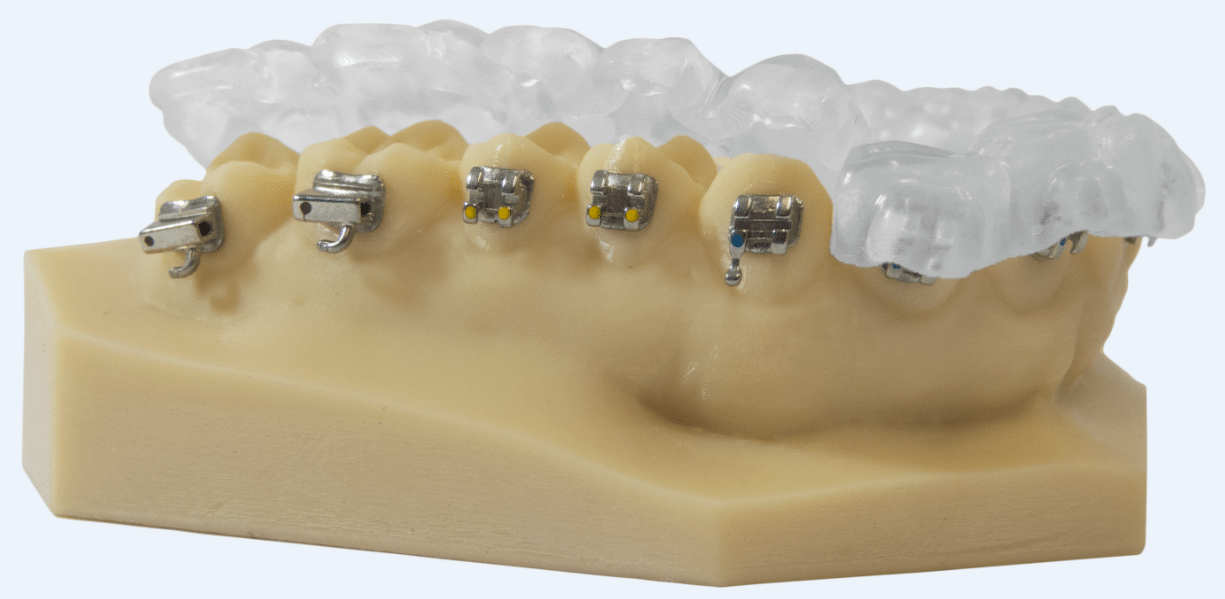

EnvisionTEC’s new E-IDB material joins the company’s industry-leading materials library for dental applications and builds highly accurate and flexible custom trays that allow for fast, accurate application of orthodontic brackets that release with ease.

In addition to printing quickly — four trays can be built in E-IDB in 45 minutes on an EnvisionTEC Vida 3D printer — the new material requires virtually no post-processing.

“EnvisionTEC’s flexible E-IDB material finally allows doctors to 3D print their own indirect bonding trays right in the office rather than rely on suppliers,” said EnvisionTEC CEO Al Siblani. “This change gives clinicians more control over their trays, and how tight or loose they prefer them, as well as the entire treatment process.”

3Shape, an EnvisionTEC partner and a global leader in 3D scanning and CAD/CAM software for the dental industry, will also be showcasing the Vida and new E-IDB capabilities in its booth at IDS, to be held March 21-25. The technologies will also be shown jointly at the upcoming American Association of Orthodontists annual session to be held April 21-25 in San Diego, Calif.

About Indirect Bonding Trays

Indirect bonding trays allow orthodontic offices to place brackets on a patient’s teeth in about half the time as individual bracket placements, which can take about two hours.

A custom tray is first created in a digital environment to match a digital representation of the patient’s mouth, making room for the specific brackets that should be adhered to each individual tooth. In fact, software to create indirect bonding trays locates the precise position on a patient’s tooth to shorten treatment times. After 3D printing the tray, a technician places the individual brackets into the tray.

The custom 3D printed tray containing all of the brackets is then placed into the patient’s mouth, quickly lining up brackets to the optimal position on each tooth. A UV light is then used to adhere the brackets to the teeth and the guide is removed, transferring all the individual brackets to the teeth.

Other Show Highlights

Also at IDS, EnvisionTEC will be previewing the new Vida cDLM high-speed 3D printer and several other recently released materials.

The Vida cDLM is the second 3D printer based on EnvisionTEC’s patented and groundbreaking Continuous Digital Light Manufacturing (cDLM) technology, which allows for accurate, high-speed 3D printing with fewer supports. The Vida cDLM will have limited availability in the second quarter, with a full production launch to follow.

The original Vida 3D printer launched in 2015 and helped drive EnvisionTEC’s unit sales up 29% in 2016 over 2015. Overall, sales of 3D printers to the dental industry grew 75% in 2016 over the prior year.

EnvisionTEC also will be showcasing E-Model, a highly accurate and durable resin that has been in development for more than a year. It is suitable for creating models for thermoformed aligners, crown and bridge models and more. The material can also be printed on EnvisionTEC’s large production 3D printers such as the Vector 3SP, which does not require consumable parts.

Additionally, EnvisionTEC will showcase new additions to its dental material library:

• E-Dent 400, which is more affordable than E-Dent 100, for the direct printing of temporary crowns, bridges and roundhouses.

• E-Gum, which creates flexible gingiva masks for integration into 3D printed dental models.

• E-Guard, a biocompatible crystal clear material for direct production of accurate night guards, bite splints and retainers.

About EnvisionTEC

EnvisionTEC is a leading global provider of professional-grade 3D printing solutions. Founded in 2002 with its pioneering commercial DLP printing technology, EnvisionTEC now sells more than 40 printers based on six distinct technologies that build objects from digital design files. The company’s premium 3D printers serve a variety of medical, professional and industrial markets, and are valued for precision, surface quality, functionality and speed. EnvisionTEC’s intellectual property includes more than 100 pending and granted patents and 70 proprietary materials. Learn more at EnvisionTEC.com.

Media Contact

Sarah A. Webster, +1-313-888-4460

swebster@envisiontec.ciwebstudio.com

Click image below for hi-res download.