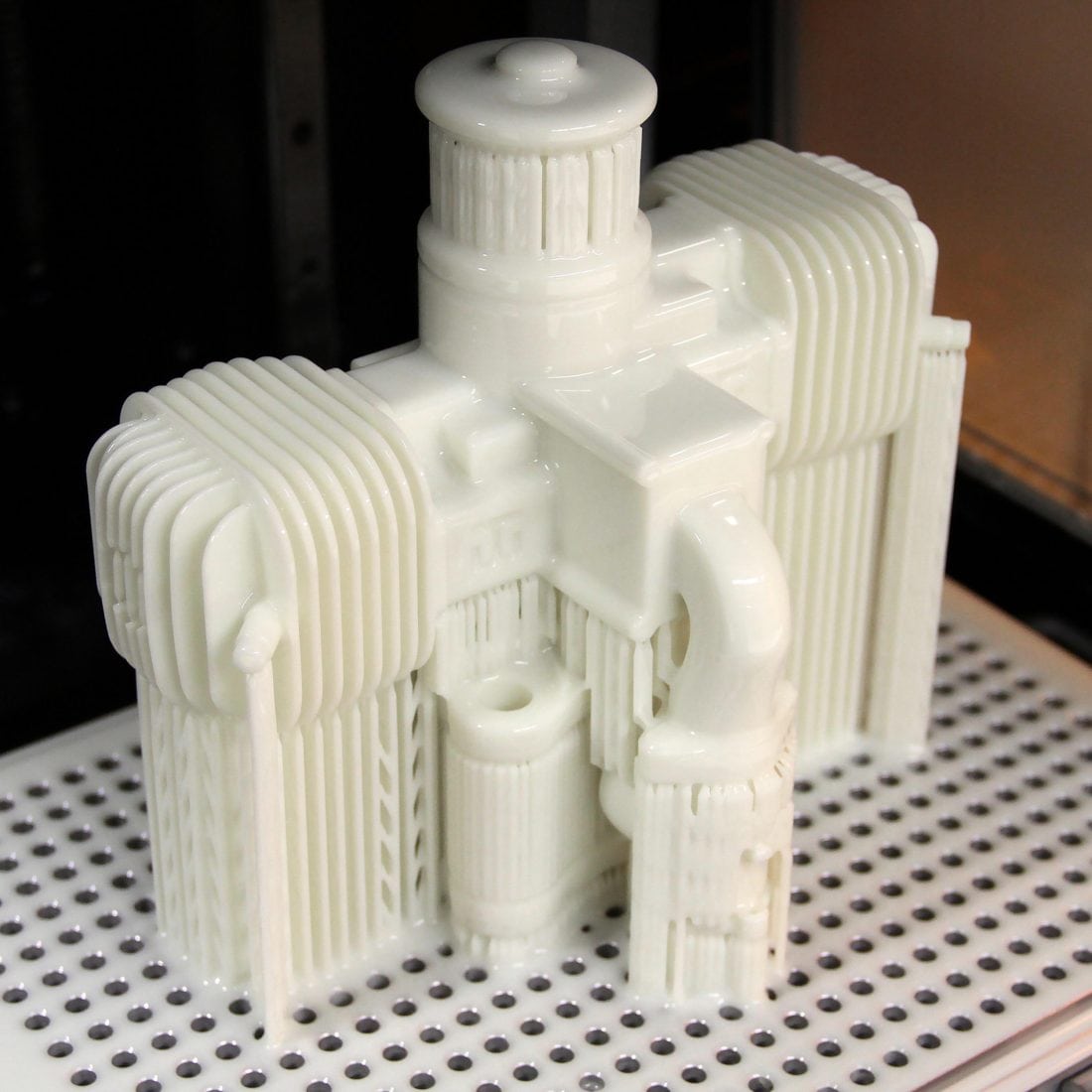

EnvisionTEC’s ULTRA 3SP Series 3D printers use ground-breaking 3SP (Scan, Spin and Selectively Photocure) technology to quickly 3D print highly accurate parts from STL files regardless of the geometric complexity. The ULTRA 3SP HD is delivered and installed with all the relevant software to enable automatic generation of supports and perfect model production. The surface quality of the printed models show no signs of stairstepping on the inner and outer surfaces. The reliability of the imaging light source and the high-speed productivity makes it the most competitive 3D printer on the market today.

Machine Properties

Build Envelope

266 x 175 x 193 mm (10.5 x 6.9 x 7.6 in.)

XY Resolution*

50 µm (0.002 in.)

Dynamic Voxel Resolution in Z (Material Dependent)

50 – 100 µm (0.002 – 0.004 in.)

Data Handling

STL

Warranty

1 year included

System Properties

- A single material is used for both build and support

- Easily removable, partially cured perforated supports

- Very few moving parts make the system user-serviceable

- Office friendly plug-and-play operation with a built-in touch screen

- Extremely reliable system utilizing 3SP (Scan, Spin, and Selectively Photocure) technology

- Low part cost due to minimal material waste

- Produce everything from concept models to functional parts

- Layerless technology with no stair stepping on inner and outer surfaces

- Quiet operation

- Footprint (L x W x H): 74 x 76 x 117 cm (29 x 30 x 46 in.)

- Optional Stand (L x W x H): 74 x 76 x 64 cm (29 x 30 x 25 in.)

- Weight: 90 kg (198 lbs)

Materials Available

Snap-fit items that require some elasticity

Strong, clear material with flexible capabilities

Prototype and end-use model printing

A glass-filled photopolymer for 3D printing injection molds

Applications

Related Printers:

Xede 3SP

EnvisionTEC’s largest 3SP option, the Xede 3SP produces excellent prototype and production parts with a build area up to 95,045 cubic cm (5800 cubic in.) and a resolution of 100 µm (0.004 in.).

Build Envelope

457 x 457 x 457 mm (18 x 18 x 18 in.)

XY Resolution*

100 µm (0.004 in.)

Primary Markets

Vector 3SP

The Vector 3SP provides excellent surface finish and speed with a build size of up to 30,316 cubic cm (1850 cubic in.) to produce everything from concept models to functional parts in 100 µm (0.004 in.) resolution.

Build Envelope

300 x 200 x 275 mm (11.8 x 7.9 x 10.8 in.)

XY Resolution*

100 µm (0.004 in.)

Primary Markets

Ultra 3SP

A great manufacturing option for a wide variety of consumer and automotive applications, the ULTRA 3SP provides 100 µm (0.004 in.) resolution and a build size of up to 9013 cubic cm (550 cubic in).

Build Envelope

266 x 175 x 193 mm (10.5 x 6.9 x 7.6 in.)

XY Resolution*

100 µm (0.004 in.)

Primary Markets

Materials Available for the Ultra 3SP HD Printer

EnvisionTEC‘s ABS Flex White is an extremely flexible ABS-like 3D printing material for technology. ABS Flex White is an ideal solution for a wide variety of applications including snap-fit items and assembly applications which require some elasticity.

![]()

![]()

![]()

![]()

![]()

![]()

ABS Hi-Impact 3SP is a tough material, suitable for high quality prototypes of items in categories such as automotive and consumer goods as well as stable enough for production-quality end use parts.

![]()

![]()

![]()

![]()

![]()

![]()

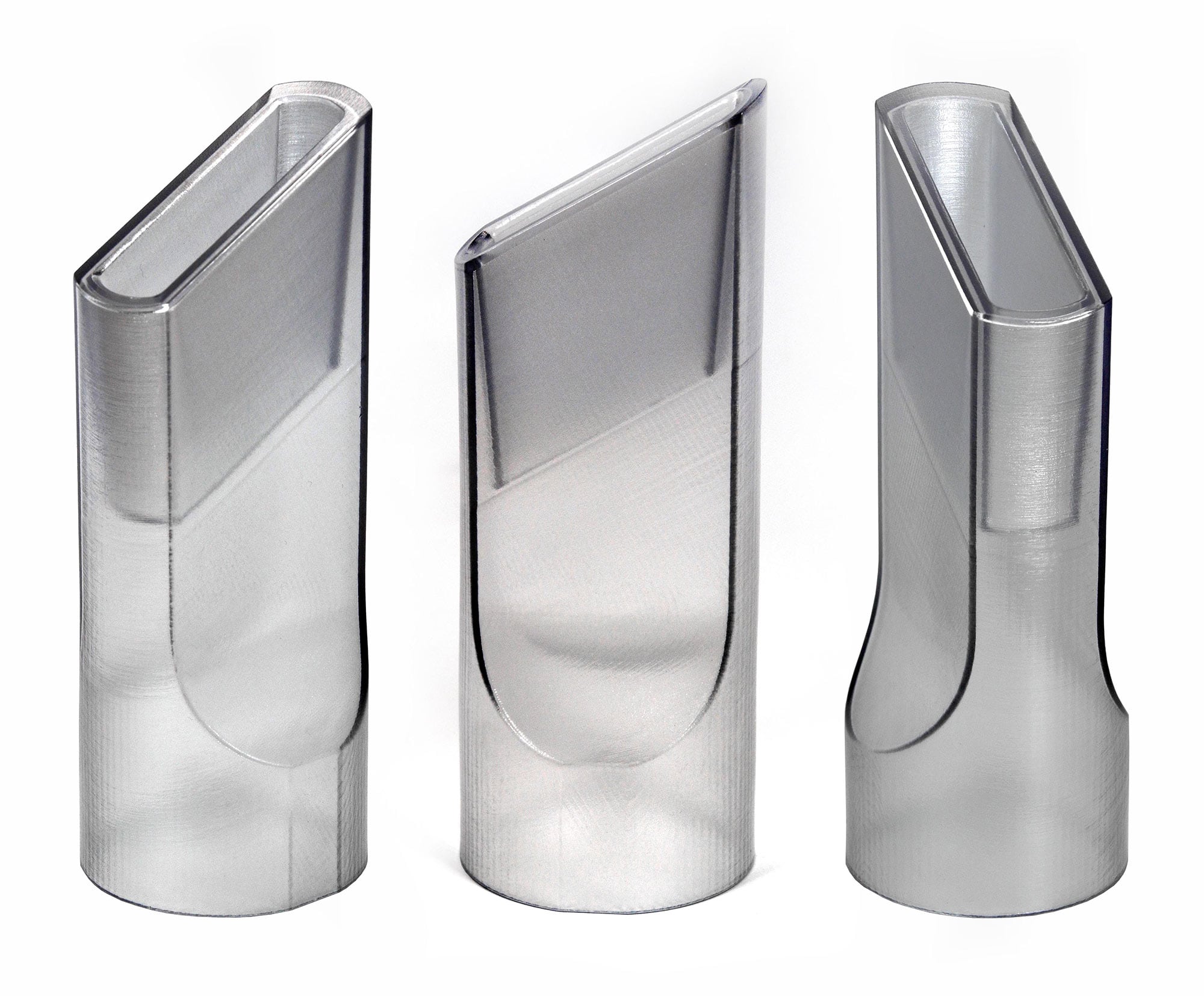

EnvisionTEC’s E-Glass 2.0 material is a transparent material for use on EnvisionTEC's 3D Printers. Featuring excellent surface finish quality and feature resolution, E-Glass 2.0 is an ideal 3D printing solution for simulating clear plastics.

![]()

![]()

![]()

![]()

![]()

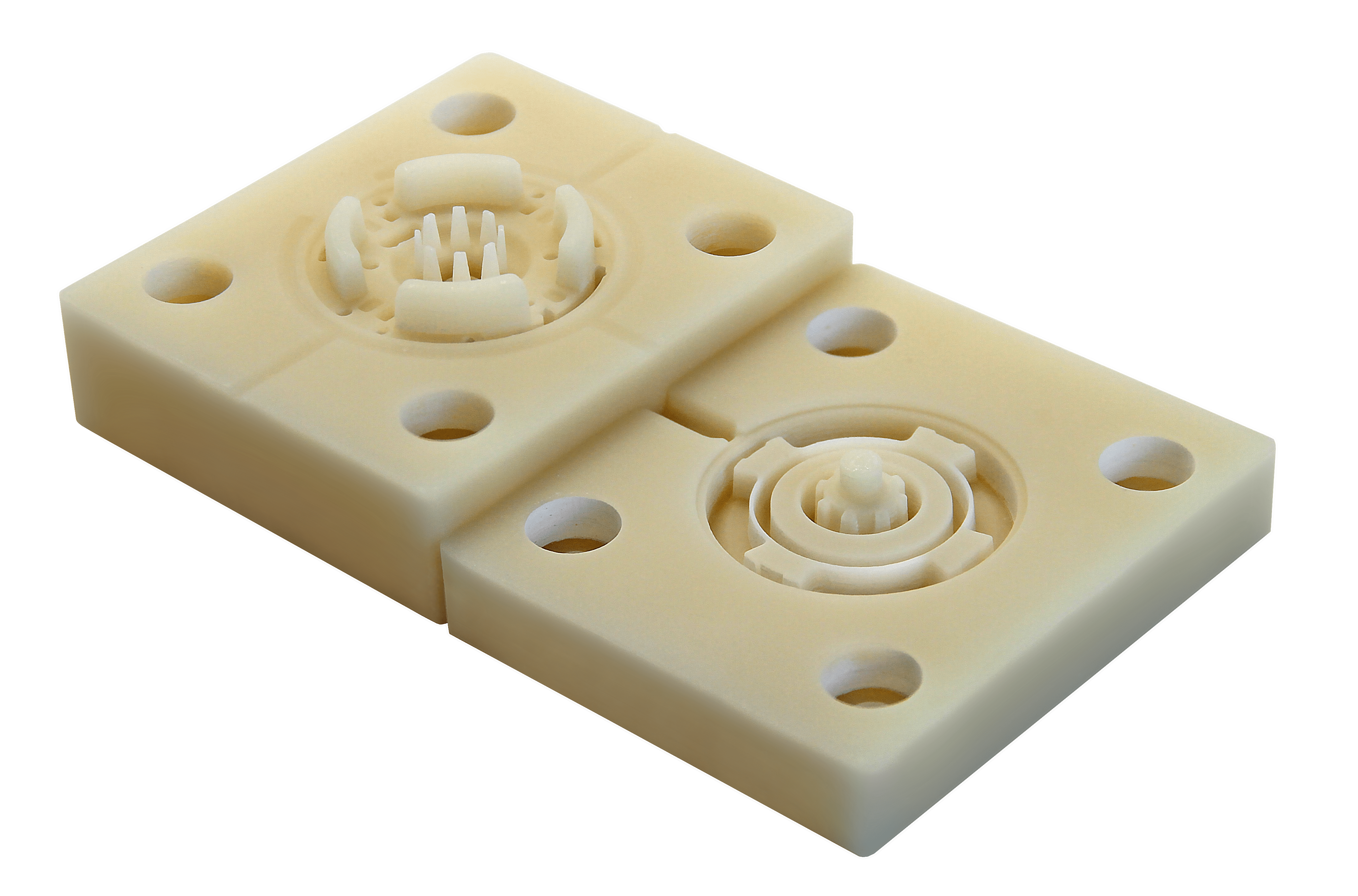

Now available in beta, E-Tool 2.0 is filled with Barium Borosilicate Glass, known for its heat and chemical resistance, to deliver injection molds that can withstand high heat and pressure. Combined with EnvisionTEC’s 3D printing technologies, E-Tool 2.0 delivers highly accurate tooling with an exceptionally smooth surface finish.

![]()

![]()

![]()

![]()

![]()