3D Printers to Transform Your Practice —

EnvisionTEC is the leading choice for orthodontic applications. Whether you are an orthodontist who is new to 3D printing or a lab who may have experience with the technology, our easy-to-use DLP technology delivers superior accuracy, surface finish and speed. We also have the industry-leading materials library for dental applications.

With solutions for both the individual clinic and laboratories serving multiple clinics, 3D printing from EnvisionTEC can help make practices far more efficient by dramatically shortening delivery times, improving service levels, while also potentially reducing costs and creating perfect fitting aligners in minutes!

Read here about how orthodontists, dentists and labs are adopting our technology rapidly with amazing results that are transforming their businesses.

Learn Why Advanced DLP Technology is Better

for Dental 3D Printing

Not all forms of 3D printing are created equal—and that truth is also evident to the visible eye within individual 3D printing processes as well.

Novices may debate whether SLA or DLP is the superior technology. But EnvisionTEC’s team of global engineers — additive manufacturing and software leaders — have developed exclusive, patent-protected processes for 3D printers that deliver fast, smooth and accurate builds, with accuracy down to 10 microns.

In this white paper, EnvisionTEC shares the technical details of why it’s DLP printers are at least twice as good as its competitors when using the same HD projectors.

Orthodontists Choose EnvisionTEC

3D Printing is Transforming the Digital Workflow

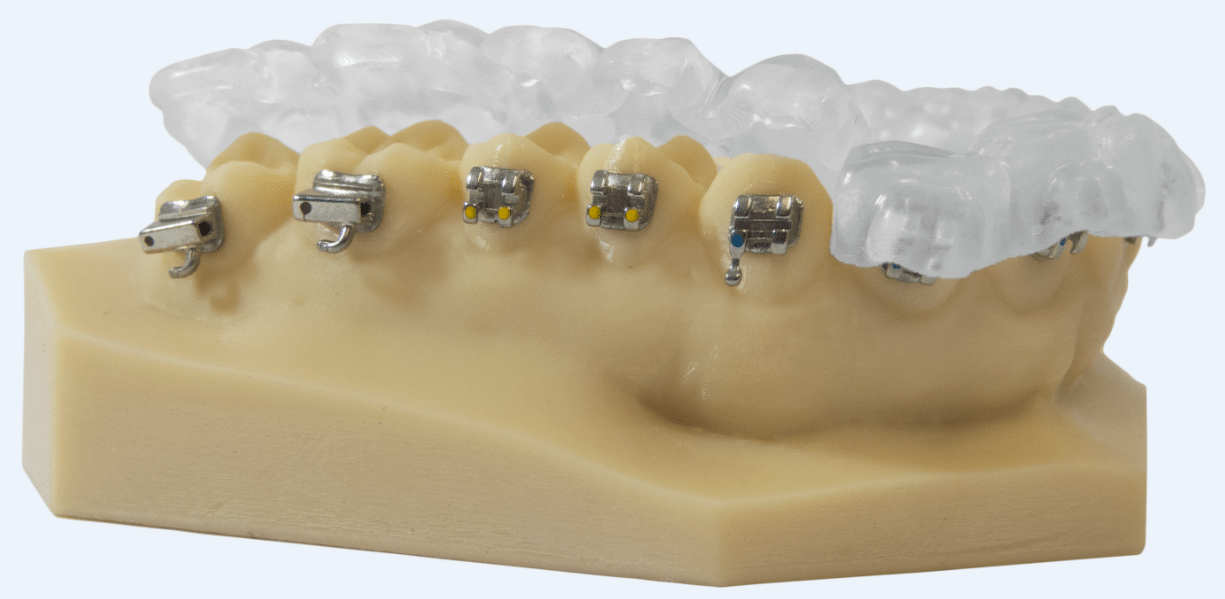

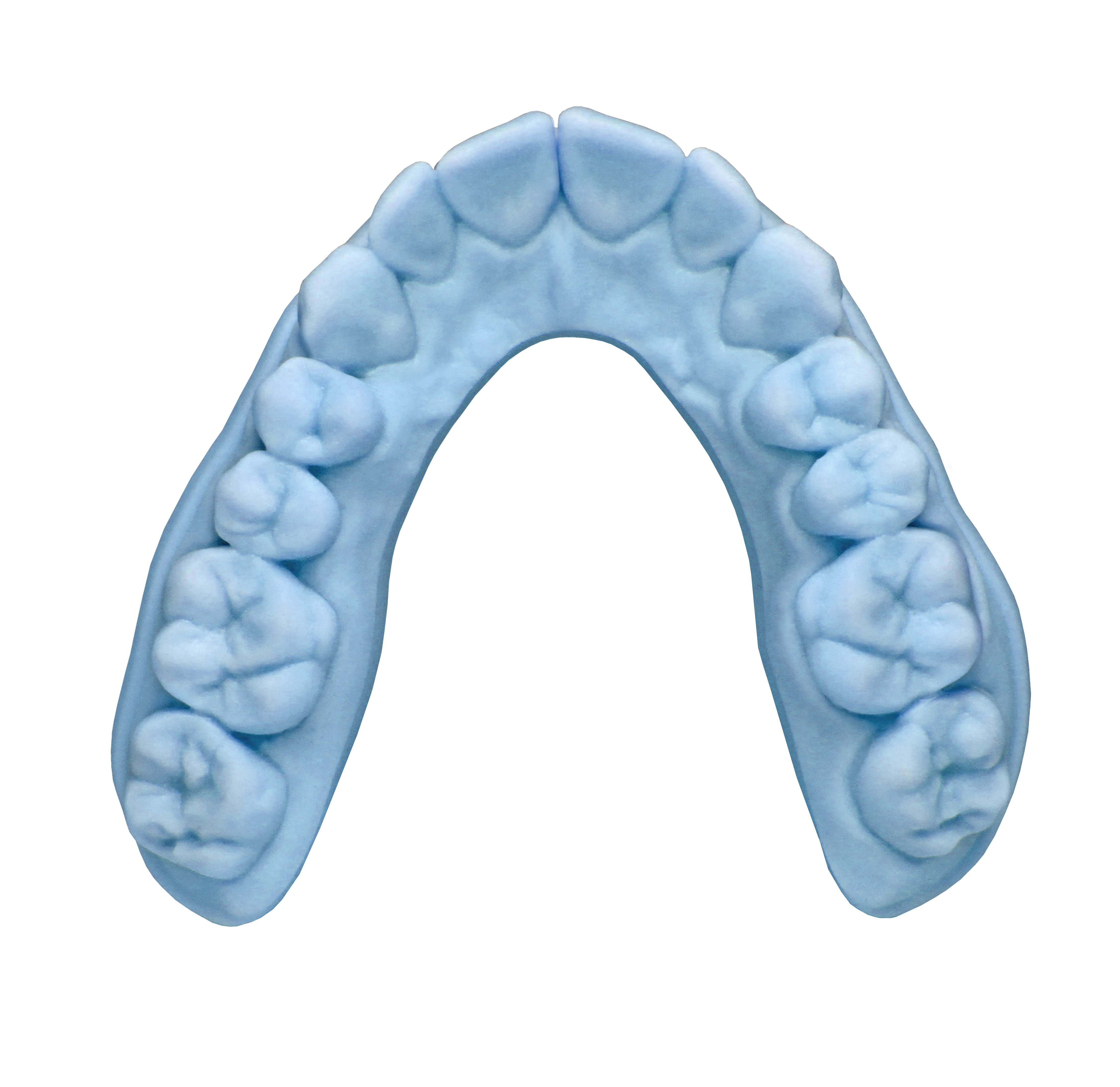

The future is free of gooey impressions and all of the complications that come with them. With an intraoral scanner, software and a thermoforming device, orthodontists can take control of tooth movement and their own appliance manufacturing, saving money and time. Dental labs can also offer time- and money-saving manufacturing of models and appliances, with advances being made all the time. Now, even indirect bonding trays can be 3D printed, saving even more time and money.

Consider how your workflow could be transformed:

Scanning

Intraoral 3D Scanners (Third Party)

The process starts with taking a 3D Scan or regular impression of your patient.

Common scanners: iTero, Lythos, 3 Shape, IOS Fastscan, Motion View, Next Engine

Planning

Orthodontic Treatment Software (Third Party)

Orthodontic Treatment Software allows you to minimize the costs and other hassles of standard appliance design and delivery. Tooth movements, appliance fabrication, and digital storage have never been easier! Orthodontic Treatment Software puts you in control of your treatment planning at a dramatic reduction in overhead.

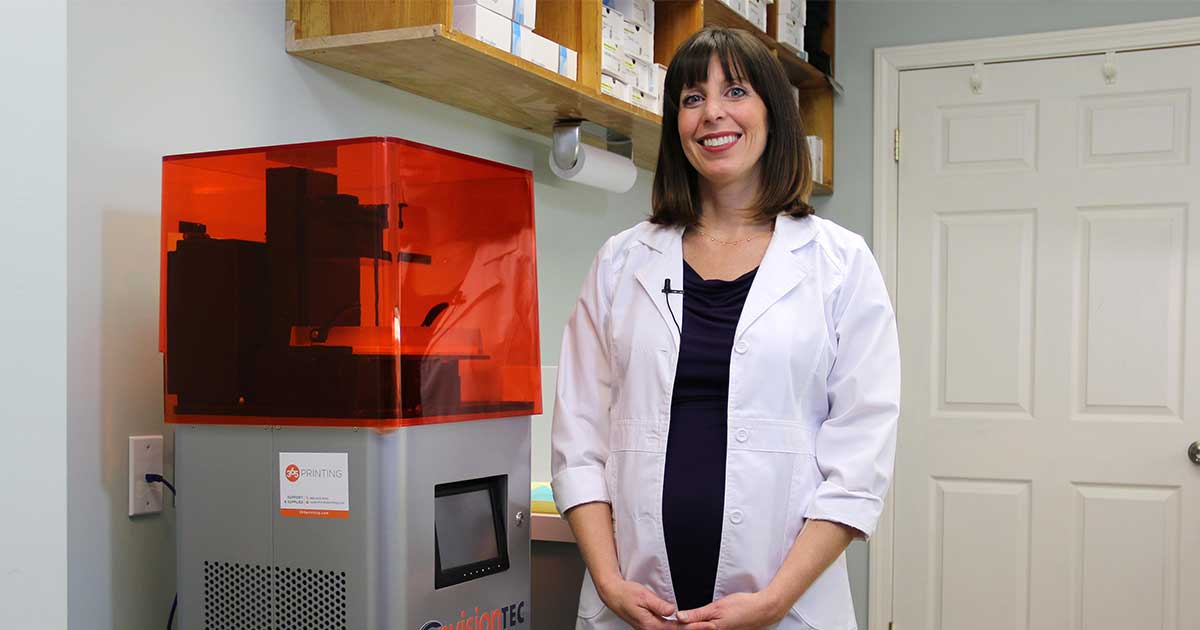

Printing

EnvisionTEC Vida 3D Printer

The Vida 3D printer is an extremely accurate desktop printer. Combined with Orthodontic Treatment Software, this combination offers your practice a tremendous ROI!

Extremely Efficient: Prints 7 models in 4 hours

Extremely accurate: Prints at 50-100 micron voxels.

1 Year Factory Warranty

Thermoforming

Thermoforming Unit (Third Party)

Thermoforming units performs the last critical step to fabricating your patients’ customized 3D aesthetic solution.

Traditional Method

Day 1

The orthodontist creates an impression.

Day 2-5

Impression is shipped to your laboratory.

Day 6-8

Technician pours the model.

Day 8-9

Technician makes the appliance.

Day 10-12

Appliance is shipped to the orthodontist.

Digital Method with EnvisionTEC 3D Printers

Day 1

The orthodontist takes an intraoral scan to create a digital file. (Third Party Scanner)

Day 1

The file is sent directly to the technician through the internet.

Day 1-3

Your lab will use an EnvisionTEC 3D printer to create the model, from which the appliance can be made.

Day 3-6

Appliance is shipped to the orthodontist.

3D Printers for the Orthodontic Industry

Designed to take you from beginner to expert in a single machine, the Envision One cDLM is the only professional 3D printer you’ll ever need. EnvisionTEC delivers an end-to-end solution including design software parameter optimization to deliver accurate parts every time with minimal supports.

Introducing the D4K Pro, the highest resolution 4K desktop 3D printer. Including the highest speed for a standard DLP printer, the D4K pro from EnvisionTEC delivers extremely accurate parts with the finest detail available. The D4K Pro is compatible with all EnvisionTEC DLP resins for the dental industry, providing essential solutions for applications from models to full dentures and everything in between.

Introducing the only DLP-based 3D printers utilizing a true 4M pixel projector with UV optics tuned to 385nm wavelength. The P4K Series delivers the highest accuracy coupled with the highest finished product functionality. Utilizing Artificial Intelligence (AI) in pixel tuning to deliver extremely high quality surface finish, the P4K delivers next generation advanced DLP technology in 3D printing.

High-volume orthodontic practices and labs will appreciate the generous build space available on the Xede 3SP Ortho, allowing for up to 49 appliance models or 77 aligner models to be produced in each job.

The Vector 3SP Ortho provides excellent surface finish and speed with a generous build size for the production of high quality orthodontic models in 100 µm (0.004 in.) resolution.

3D Printing Materials for the Orthodontic Industry

E-Guard is a biocompatible transparent material for the production of accurate orthodontic bite splints and night guards. The results produced by combining E-Guard with EnvisionTEC technology are superior to traditional methods of manufacturing bite guards and night guards. It is a clear material, allowing for maximum visibility.

![]()

E-Tray is a 3D printing material for use in producing individual customized impression trays.

![]()

KeySplint Soft for EnvisionTEC is a a 3D printing resin ideal for printing splints and night guards.

![]()

E-Model Beige printing material for DLP and cDLM 3D printers is the perfect choice for orthodontic models for thermoforming aligners over.

![]()

NextDent Indirect Bonding Tray is a biocompatible Class I material for orthodontic applications.

![]()

E-Model HS is a high speed 3D printing material for use in producing orthodontic arch models extremely quickly on EnvisionTEC cDLM 3D printers.

![]()

E-SepFree is easy to release when directly building orthodontic appliances as it does not require a separator. It is also easy to carve when hand contouring contact areas, opening interproximals, and much more.

![]()

A material developed specifically for the rapid production of highly accurate, scannable dental models. Looks and feels similar to traditional gypsum models.

![]()

E-OrthoShape is a grey ABS-like material that prints in 100 micron layers. It is recommended for the affordable volume production of models on which to produce clear thermoformed aligners by orthodontic professionals.

![]()

The Vida has really helped our office with the work-flow of creating a retainer It's a really clean, hygienic process and ultimately the biggest difference is that I have yet to put a retainer in someone's mouth and find that it doesn't fit. That would happen about once a week when we were using the old technology.

Dr. Kelly Walters, Owner of Dutchess Orthodontics

The Vida has really helped our office with the work-flow of creating a retainer It's a really clean, hygienic process and ultimately the biggest difference is that I have yet to put a retainer in someone's mouth and find that it doesn't fit. That would happen about once a week when we were using the old technology.

Dr. Kelly Walters, Owner of Dutchess Orthodontics “I scan the case, send it to them (OrthoSelect), and they return an already decently set up case. I then spend 3 minutes fine-tuning the final positions of the teeth and hit approve. They then actually go in and design the indirect bonding tray for me, so I don’t have to. Then they send it to my (EnvisionTEC) Vida printer, and I hit print. Now I have a digital IDB solution that only requires about 3 minutes of doctor time. ... That's a huge value position."

“I scan the case, send it to them (OrthoSelect), and they return an already decently set up case. I then spend 3 minutes fine-tuning the final positions of the teeth and hit approve. They then actually go in and design the indirect bonding tray for me, so I don’t have to. Then they send it to my (EnvisionTEC) Vida printer, and I hit print. Now I have a digital IDB solution that only requires about 3 minutes of doctor time. ... That's a huge value position." Incorporating OrthoSelect and the EnvisionTEC Vida into our indirect bonding procedures has greatly changed the amount of preparation involved. We have scanned and printed our models for several years. The lab time it requires to make your own IDB trays can be quite time consuming. The multistep process can often require several hours. Implementing DIBS has reduced the workload by at least 60 percent. We are now able to 3D print only indirect bonding trays and simply place the brackets in them the day of the initial bonding. It has made us more efficient on a daily basis and freed up so much time to concentrate on patients.

Incorporating OrthoSelect and the EnvisionTEC Vida into our indirect bonding procedures has greatly changed the amount of preparation involved. We have scanned and printed our models for several years. The lab time it requires to make your own IDB trays can be quite time consuming. The multistep process can often require several hours. Implementing DIBS has reduced the workload by at least 60 percent. We are now able to 3D print only indirect bonding trays and simply place the brackets in them the day of the initial bonding. It has made us more efficient on a daily basis and freed up so much time to concentrate on patients. 3D printing is putting more tools into the orthodontists' hands. ...

It changes the practice dramatically because you have a faster turnover time and you have more freedom of movement versus working with an intermediary.

3D printing is putting more tools into the orthodontists' hands. ...

It changes the practice dramatically because you have a faster turnover time and you have more freedom of movement versus working with an intermediary.