With applications so far-reaching, it is becoming more and more important that students are not only exposed to 3D printing, but also to have experience in it to benefit their future careers.

High schools, colleges and universities are quickly adopting 3D printing technology to allow their students to be at the forefront of this technological advance. With applications so far-reaching, it is becoming more and more important that students are not only exposed to 3D printing, but also to have experience in it to benefit their future careers. Research is relying more heavily on 3D printing than ever before, from prototyping to bioprinting. At a younger level, elementary and middle school students can also benefit from the ability to see their ideas come to life in a tangible form. Teachers can print models of anything they might want to demonstrate to their classes as needed.

3D Printers for the Education Industry

The D4K PRO Industrial is built on the most reliable 4K UV DLP projector and includes EnvisionTEC's patented PSA for low separation forces. Brought to you by the original inventors of DLP 3D printing technology.

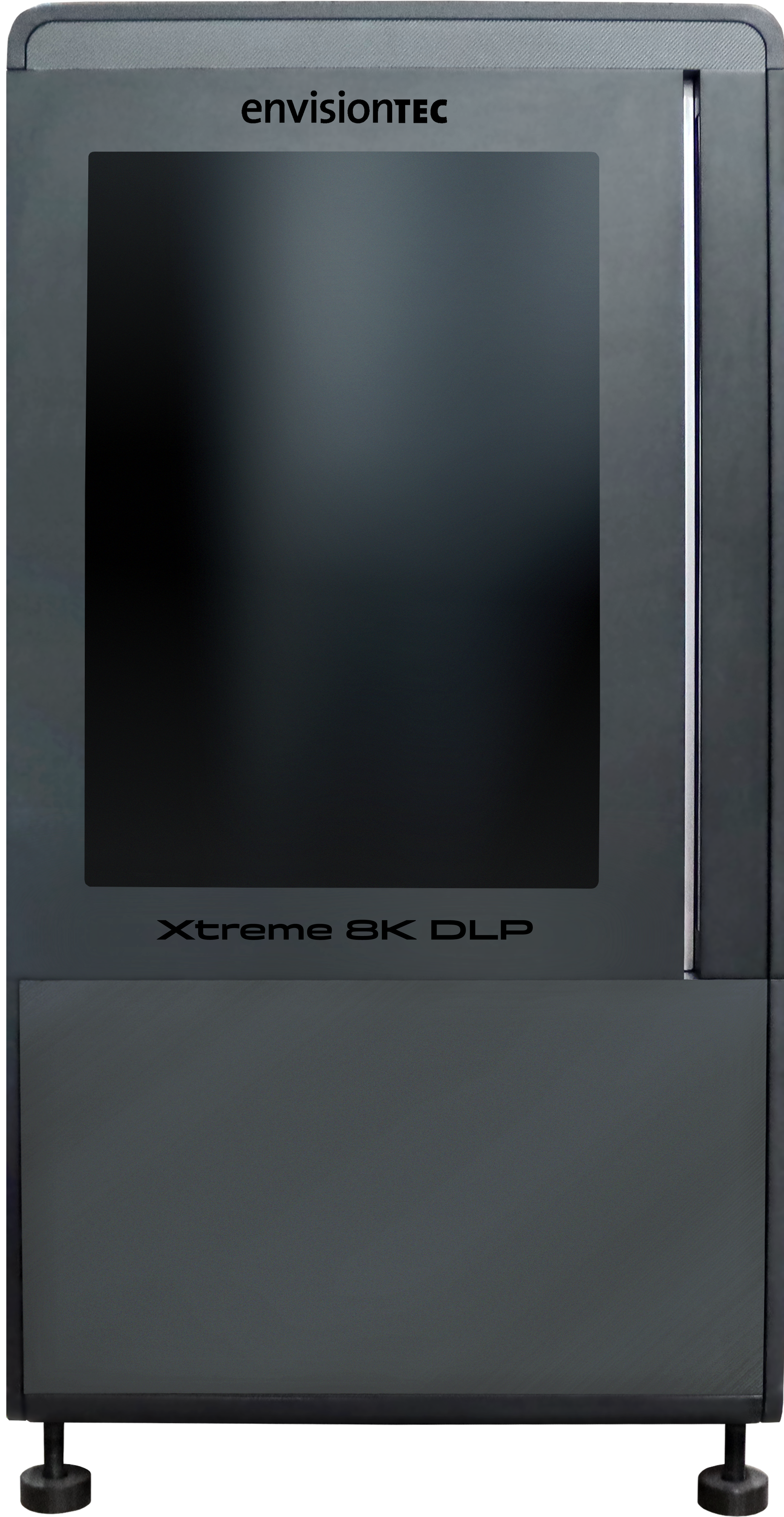

The Xtreme 8K DLP uses dual 4K projector DLP technology to quickly 3D print highly accurate parts from STL files regardless of geometric complexity. With a large selection of materials, you will be able to produce high-quality end-use parts for a variety of applications, including industrial and medical items. A heated material vat allows for additional materials with highly desirable properties.

Perfect for a wide variety of 3D printing applications, the Envision One cDLM is capable of printing up to 45 mm/hour, material dependant.

EnvisionTEC's largest 3SP option, the Xede 3SP produces excellent prototype and production parts with a build area up to 95,045 cubic cm (5800 cubic in.) and a resolution of 100 µm (0.004 in.).

The Vector HD 3SP is ideal for those who need large parts up to 30,316 cubic cm (1850 cubic in.) with a resolution of 50.8 µm (0.002 in.). High detail parts with smooth surface finishes make the Vector HD 3SP an ideal option for a wide variety of applications.

The Vector 3SP provides excellent surface finish and speed with a build size of up to 30,316 cubic cm (1850 cubic in.) to produce everything from concept models to functional parts in 100 µm (0.004 in.) resolution.

The ULTRA 3SP HD provides the same excellent surface finish and speed as the original ULTRA 3SP, but adds an incredible 50 µm (0.002 in.) resolution capability to your builds.

A great manufacturing option for a wide variety of consumer and automotive applications, the ULTRA 3SP provides 100 µm (0.004 in.) resolution and a build size of up to 9013 cubic cm (550 cubic in).

Introducing the only DLP-based 3D printers utilizing a true 4M pixel projector with UV optics tuned to 385nm wavelength. The P4K Series delivers the highest accuracy coupled with the highest finished product functionality. Utilizing Artificial Intelligence (AI) in pixel tuning to deliver extremely high quality surface finish, the P4K delivers next generation advanced DLP technology in 3D printing.

The Vida cDLM delivers outstanding surface quality with no signs of stairstepping. With the largest build envelope available in cDLM technology, the Vida cDLM allows for high quality results from a manufacturer with more than 15 years of experience in 3D printing technologies.

3D Printing Materials for the Education Industry

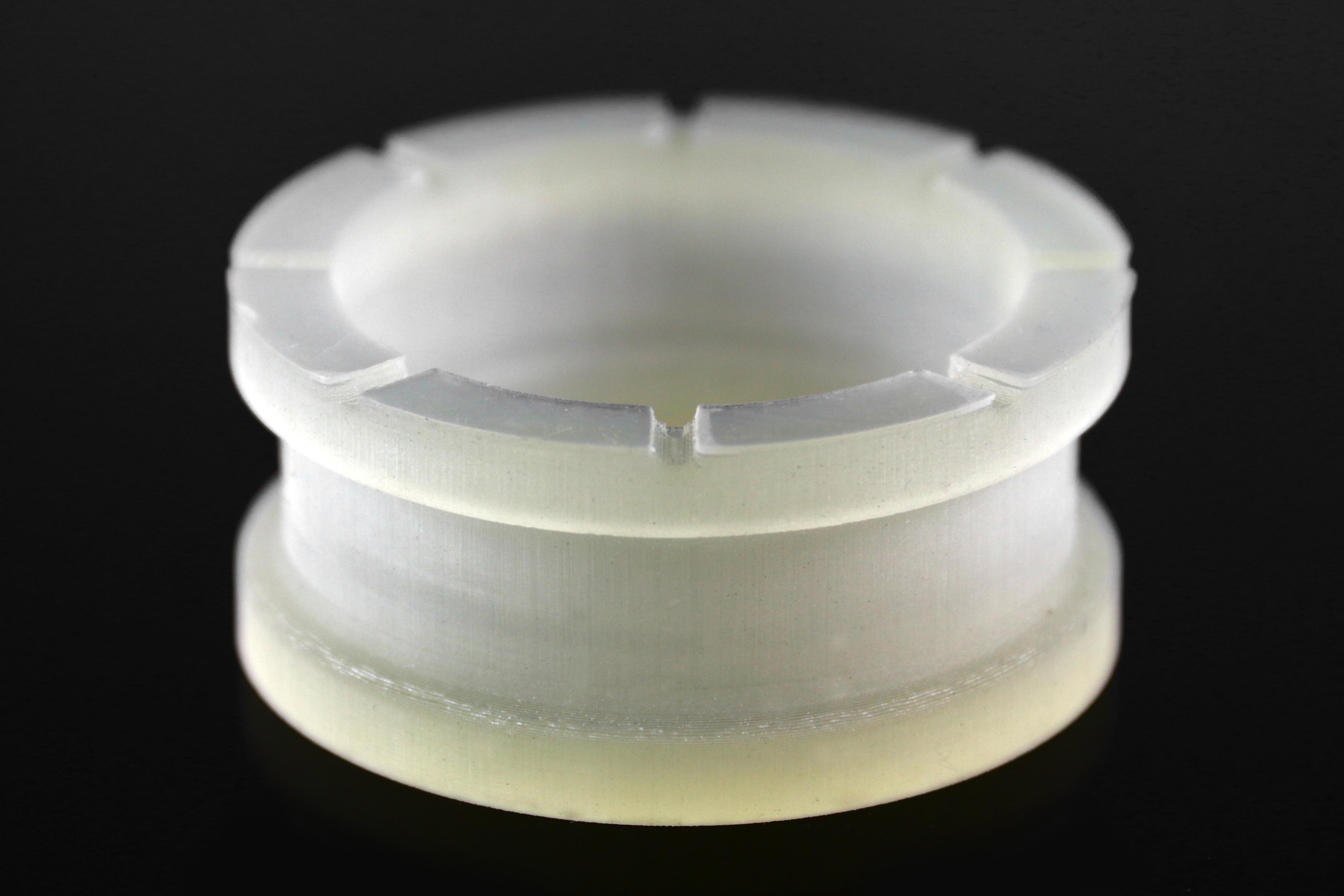

EnvisionTEC‘s ABS Flex White is an extremely flexible ABS-like 3D printing material for technology. ABS Flex White is an ideal solution for a wide variety of applications including snap-fit items and assembly applications which require some elasticity.

![]()

![]()

![]()

![]()

![]()

![]()

A semi-translucent silicone, E-UA90 is a good for general purpose elastomer parts such as robotic grippers.

![]()

![]()

![]()

![]()

![]()

![]()

A semi-translucent silicone, E-UA40 has good tear strength and excellent energy rebound. It is also good for general purpose elastomer parts such as robotic grippers.

![]()

![]()

![]()

![]()

E-Aquasol is a water-soluble 3D printing resin, allowsing industrial manufacturers to shell-cast thin-walled parts with high feature resolution.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

EnvisionTEC's E-RE90 is an elastomeric material with a tough, rubber-like performance, allowing for the 3D printing of parts previously made from technical foams, rubbers, or polyurethanes.

![]()

![]()

![]()

![]()

![]()

Loctite E-3840 is low viscosity, one-component light-cure acrylic resin used for prototyping via digital light processing (DLP) or Continuous Digital Light Manufacturing (cDLM). It cures with short exposure times which results in fast print speeds and provides very high print resolution which is ideal for parts that require fine features.

![]()

![]()

![]()

![]()

![]()

Loctite E-5015 is a one-component, light-cure silicone resin with high durability and flexibility. It offers high resolution printing of shore A70 silicone with good print-speeds.

![]()

![]()

![]()

![]()

![]()

Loctite E-3843 is a black resin that may be used for prototyping or functional parts production. It offers good Impact resistance and thermal stability making it suitable for many demanding Engineering applications.

![]()

![]()

![]()

![]()

![]()

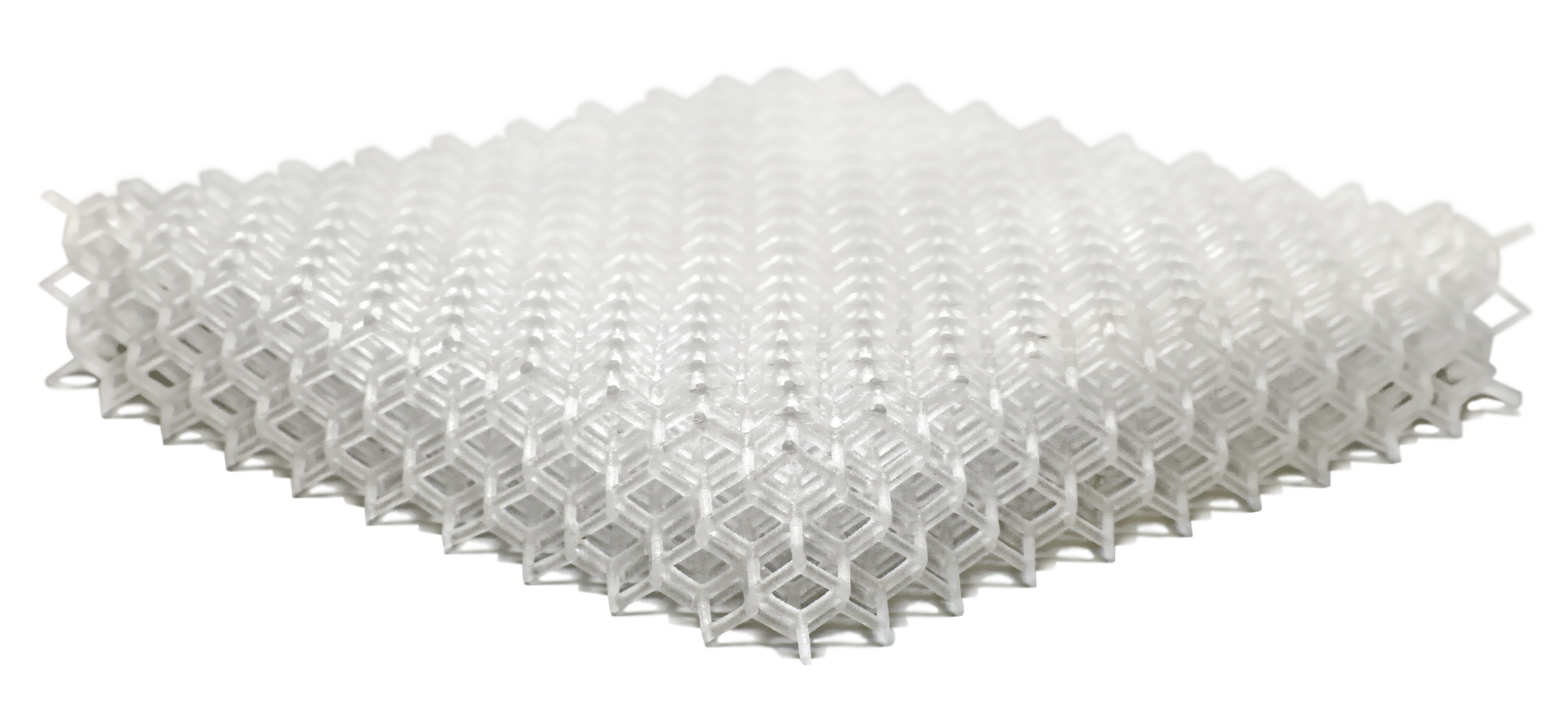

High flexural modulus and strength in a hydrophobic material that produces super tough parts, with nearly 4x the impact resistance as most engineering plastics.

![]()

![]()

![]()

EnvisionTEC‘s E-ABS Tough is an extremely tough ABS-like 3D printing material. E-ABS Tough is an ideal solution for a wide variety of applications including snap-fit items and assembly applications which require some elasticity.

![]()

![]()

![]()

![]()

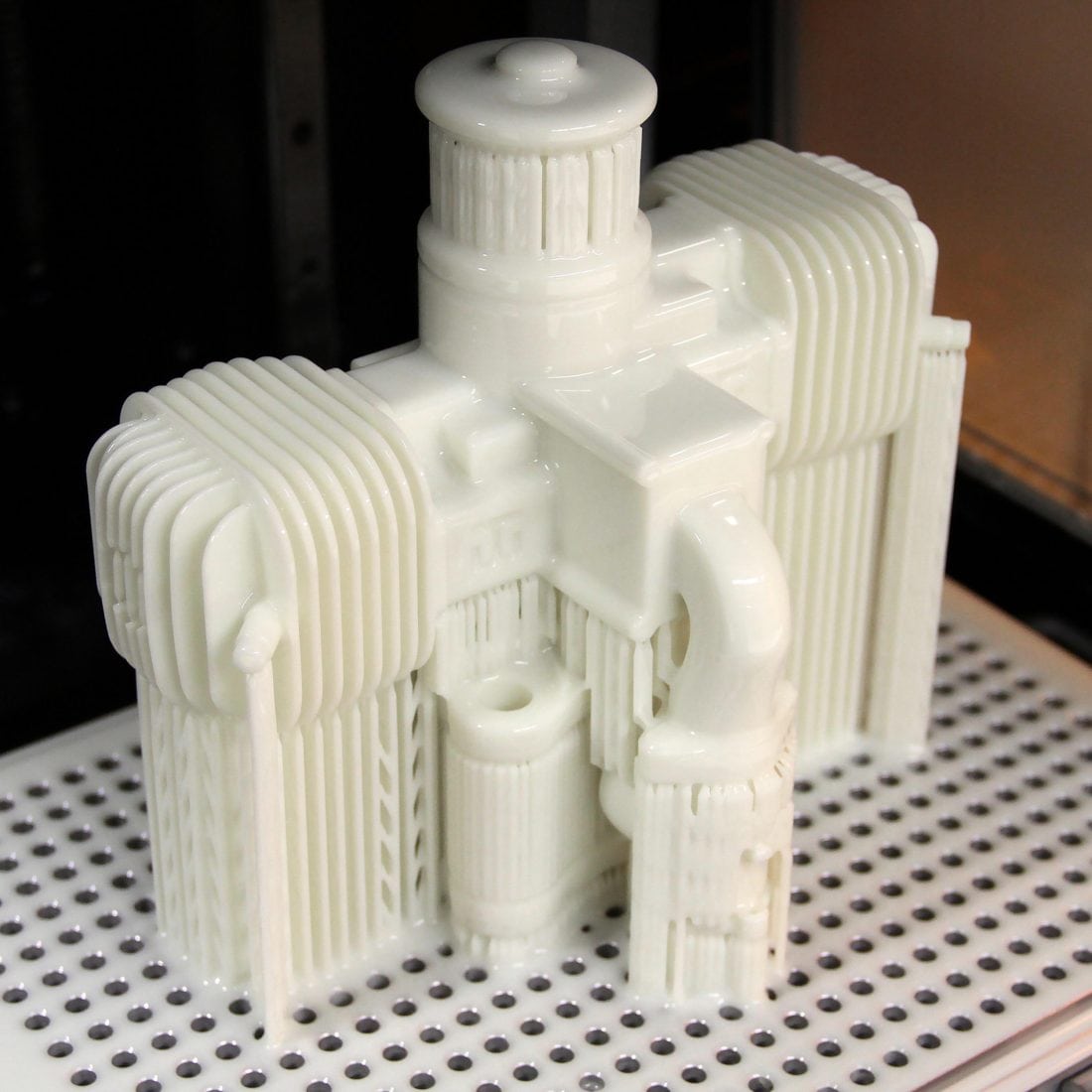

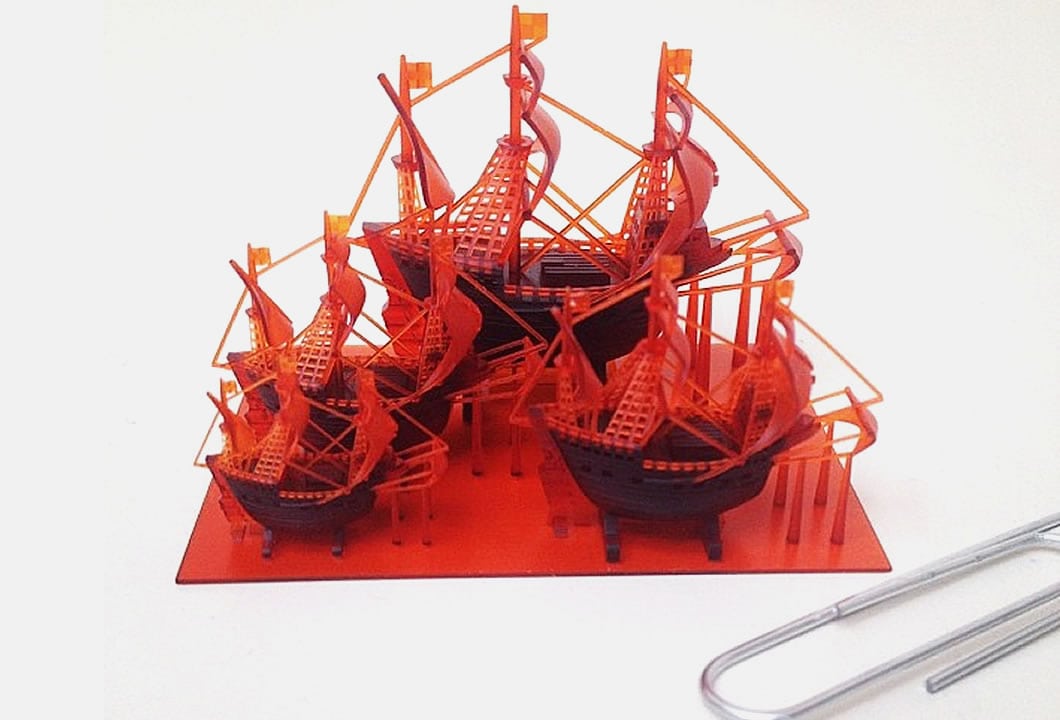

A popular line of photosensitive resins that contain ceramic particles, EnvisionTEC's RC materials build tough and stiff parts at very high resolutions. Parts made with these materials are also resistant to high temperatures and are ideal for silicone molding, pump housings, blades, test parts for wind tunnels, light reflectors and various automotive applications. These materials are also perfect for high detail jewelry and animation applications and can be finished with a variety of methods including painting or plating.

![]()

![]()

![]()

![]()

![]()

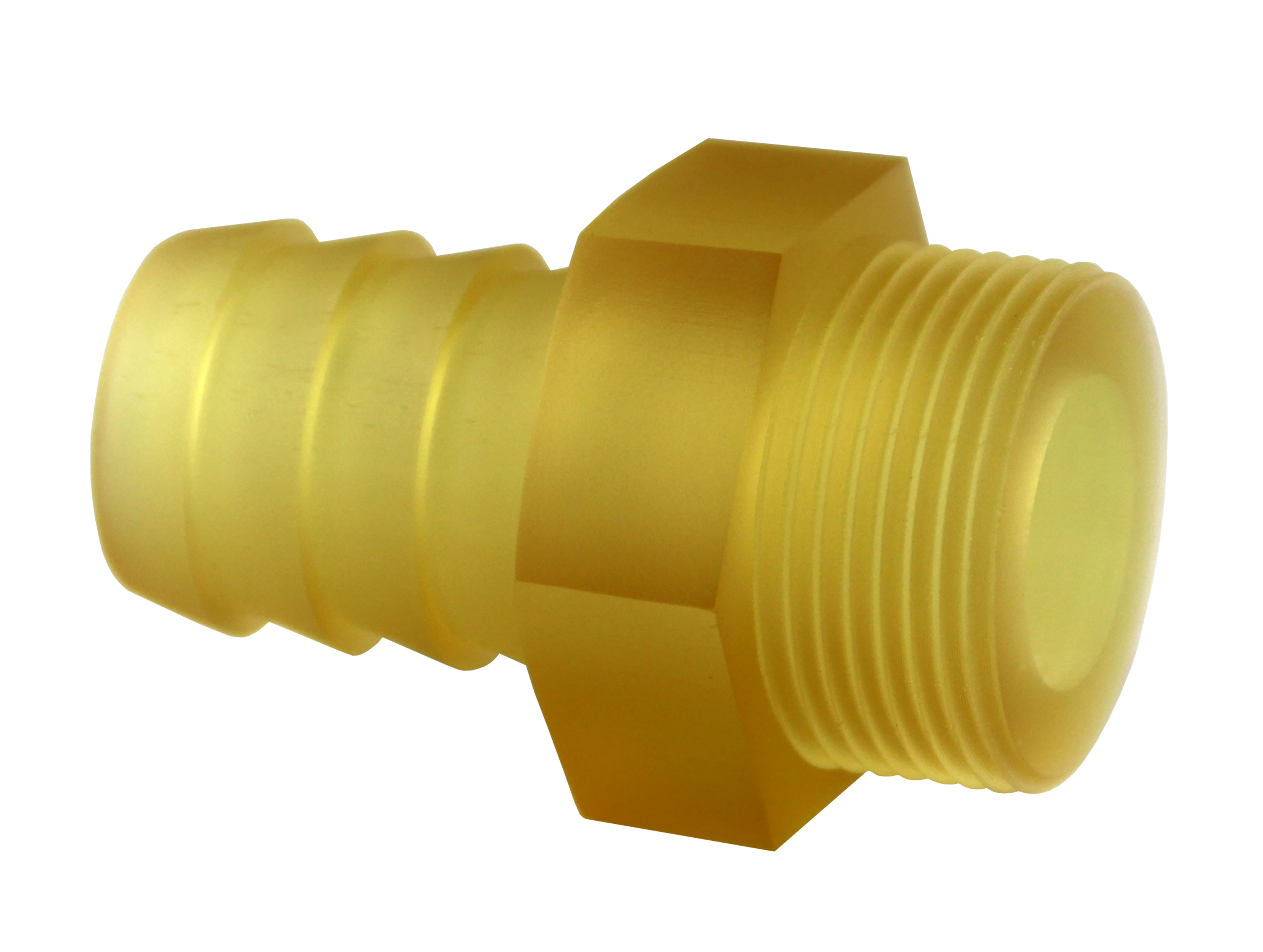

R5 3D printing material is a liquid photopolymer that produces robust, accurate, and functional parts. Exhibits superior fatigue properties, strong memory retention, and high quality up-facing and down-facing surfaces. Offering a good balance of properties between rigidity and functionality. Parts that mimic polypropylene. Ideal for master patterns in rubber molding applications.

![]()

![]()

![]()

![]()

Accurate and functional resin for producing robust and durable parts. Pro Gray 3D Printer Material is a liquid, photo-reactive acrylate with a wide processing latitude, which is used to produce parts with high quality up-facing and down-facing surfaces.

![]()

![]()

![]()

![]()

A popular production casting material, PIC 100 is ideal for printing jewelry, dental and other parts requiring exceptional detail and surface finish. In jewelry, PIC is recommended for pieces up to 5 grams finish weight, such as bridal jewelry.

![]()

![]()

![]()

![]()

![]()

The latest breakthrough in extremely durable photopolymers for use in producing very accurate parts with high feature detail on EnvisionTEC’s 3D printers. With added stability and surface quality, this material produces parts with high impact resistance similar to thermoplastics.

![]()

![]()

![]()

![]()

![]()

High temperature molding material for non-metal masters dramatically changes 3D printing capabilities for manufacturers. With a heat deflection temperature of 140°C straight out of the machine, high definition parts printed in HTM140 can be directly vulcanized in rubber, eliminating the need for a metal master.

![]()

![]()

![]()

![]()

![]()

![]()

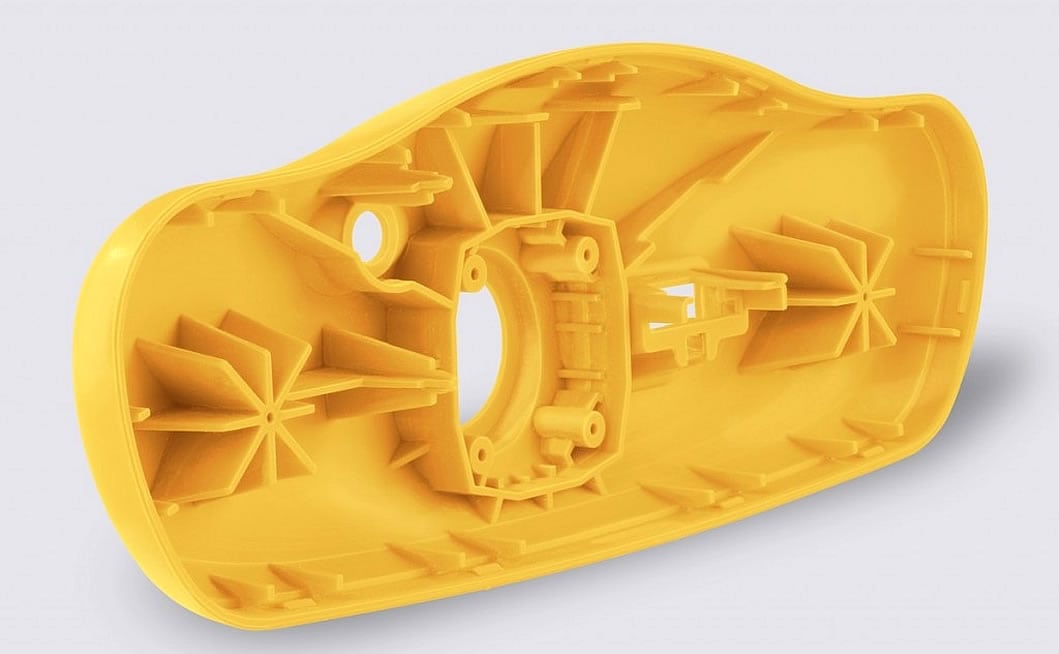

ABS Hi-Impact 3SP is a tough material, suitable for high quality prototypes of items in categories such as automotive and consumer goods as well as stable enough for production-quality end use parts.

![]()

![]()

![]()

![]()

![]()

![]()

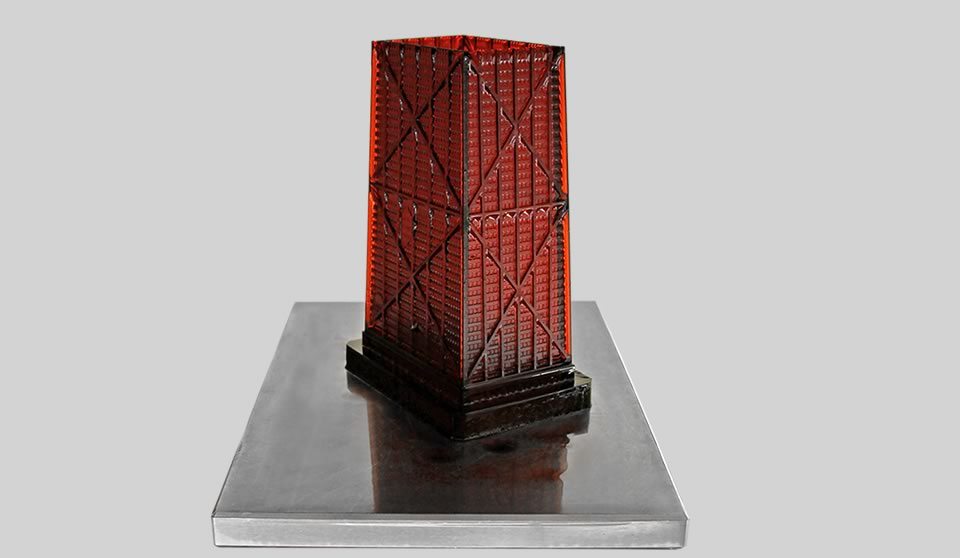

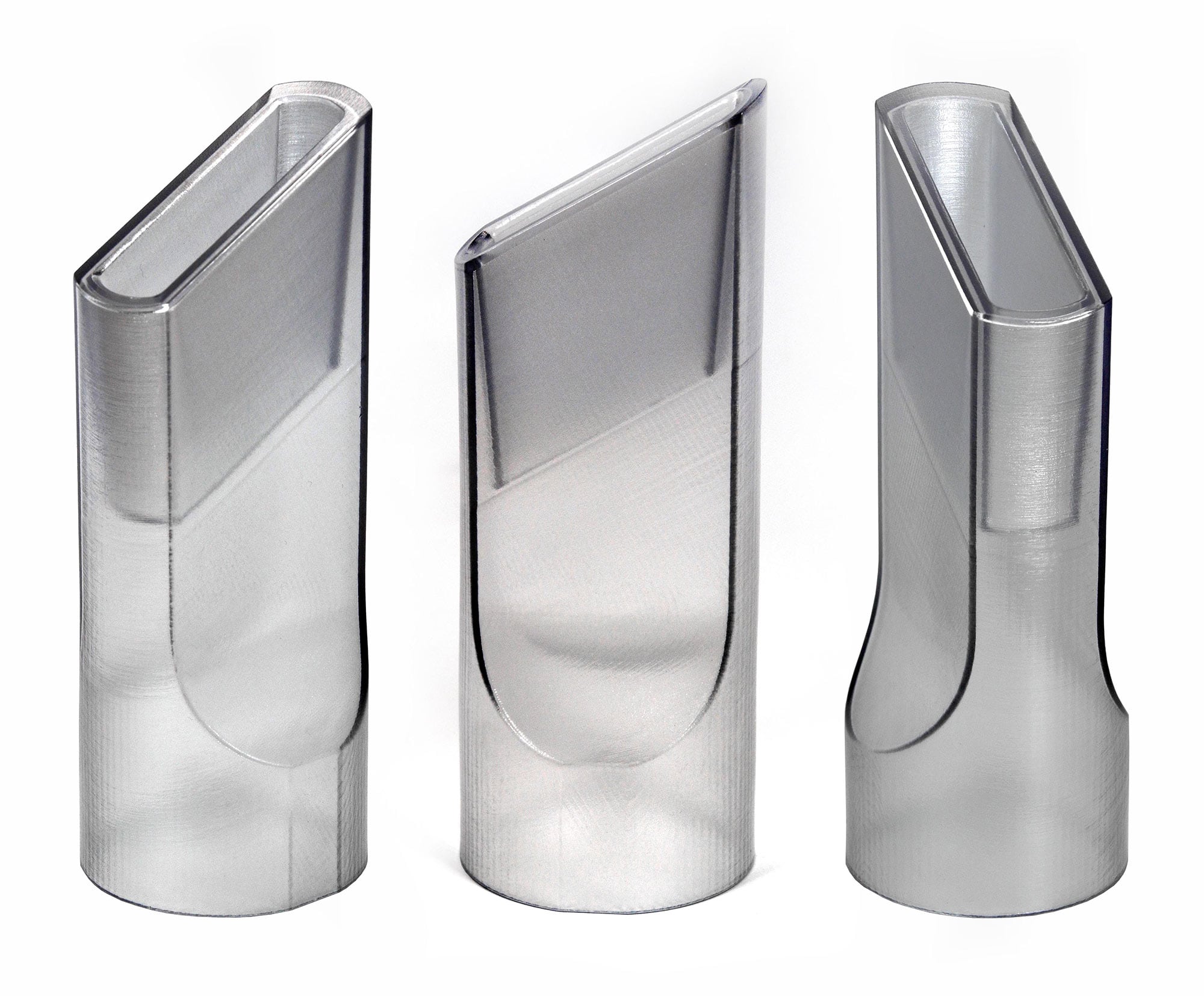

EnvisionTEC’s E-Glass 2.0 material is a transparent material for use on EnvisionTEC's 3D Printers. Featuring excellent surface finish quality and feature resolution, E-Glass 2.0 is an ideal 3D printing solution for simulating clear plastics.

![]()

![]()

![]()

![]()

![]()

R11 3D printing material is a liquid photopolymer that produces robust, accurate, and functional parts. Exhibits superior fatigue properties, strong memory retention, and high quality up-facing and down-facing surfaces. Offering a good balance of properties between rigidity and functionality. Parts that mimic polypropylene. Ideal for master patterns in rubber molding applications.

![]()

![]()

![]()

![]()

R5-385 material is an update on the original R5 material, one of EnvisionTEC's earliest materials still in use around the world, re-engineered for optimal performance in 3D printers utilizing 385nm wavelength light sources.

![]()

![]()

![]()

![]()

![]()

![]()