UK Based Dental Startup Trusts EnvisionTEC to Provide the Best Dental Models

3D Printed Dental Models, based in Sunderland, UK, was founded by brothers Louis and Liam Monte in June 2018. The brothers identified a gap in the market and tailored their business model to capitalise on the growing requirement within dental for ‘additive manufacturing’, using 3D printers to create layered 3D models.

3D Printed Dental Models saw that although a lot of dentists, labs and orthodontists were being pushed to switch to digital techniques, many did not have facilities in house, and there were few external businesses able to support them.

Why 3D printing?

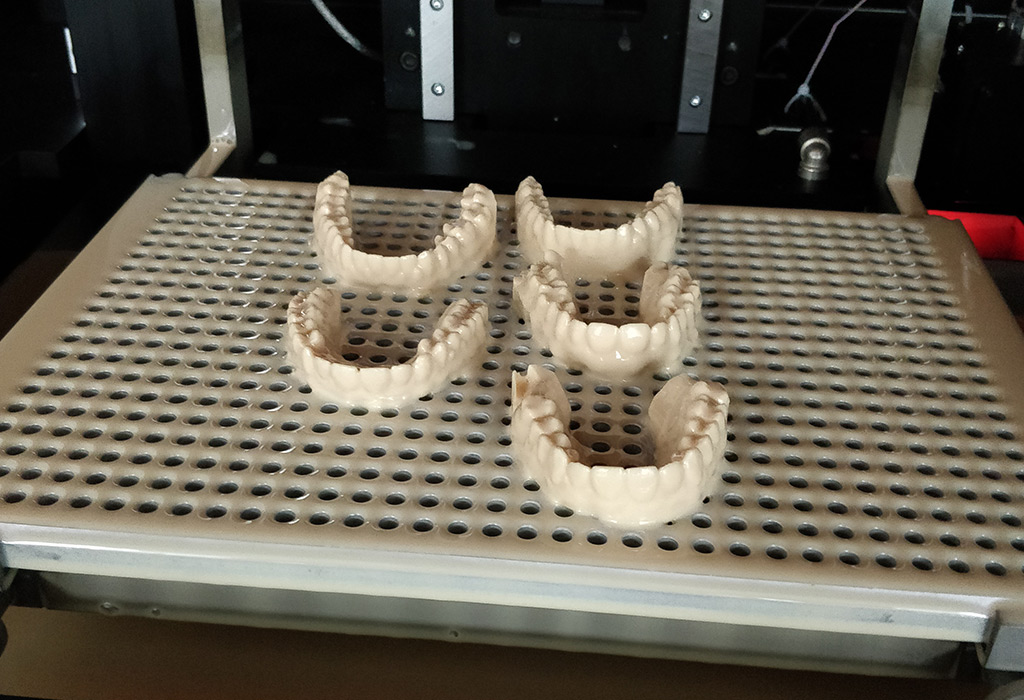

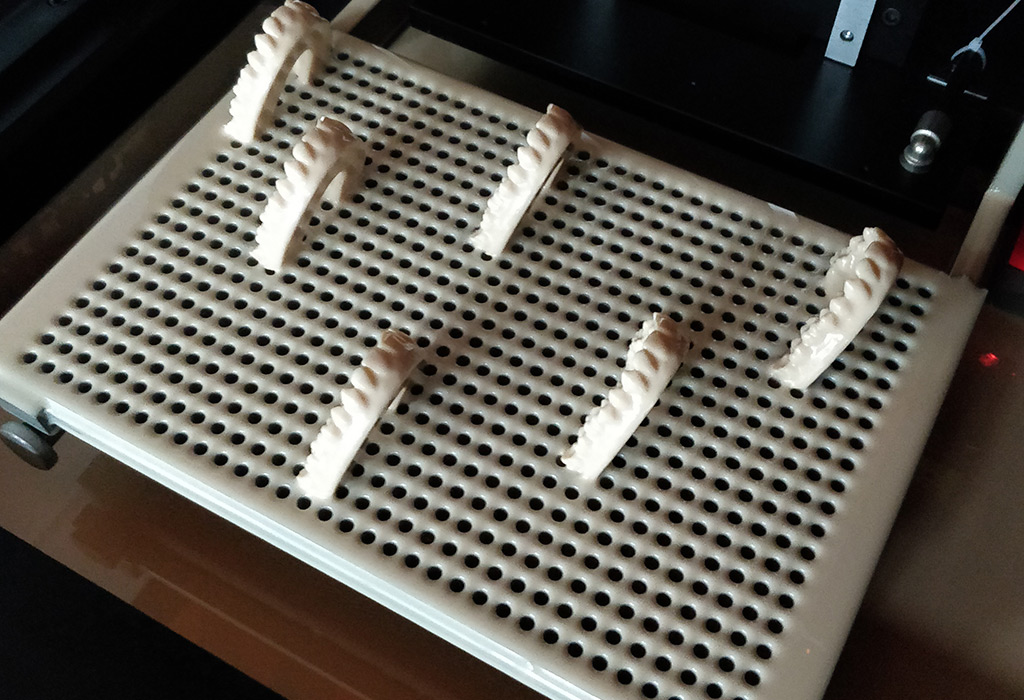

3D printing is becoming a key element in the manufacture of dental and orthodontic appliances. 3D printing provides a superior surface finish and fit compared to traditional methods. These appliances can also be manufactured faster, resulting faster patient turnaround.

3D Printed Dental Models saw that by investing in the correct 3D printers and technology it could fill the niche, and act as a third party in the production of these dental models and appliances.

Why EnvisionTEC?

With many competing 3D printer brands in the market the team had to ensure that their investment would build models with the highest accuracy, out performing those produced via traditional methods and the desktop printers being commonly used within the industry. They needed to produce models quickly and in large batches without loss of quality.

To this aim, and being new to the 3D printing industry at the time, the brothers ensured that they had investigated all of their options before settling on the printer and technology that fitted their needs.

They first encountered EnvisionTEC at FormNext 2017 where they were impressed with the print quality. There were also a number of other SLA and DLP printers considered, including FormLabs and Carbon, but the choice ultimately came down to Carbon and EnvisionTEC branded machines.

“There were a number of areas in which we felt EnvisionTEC was superior to the competition, but the one most important to us was the quality and detail of the final product. We were also very impressed with the speed of the technology and the size of the build platform on the larger machines.” - Louis Monte, Director, 3D Printed Dental Models

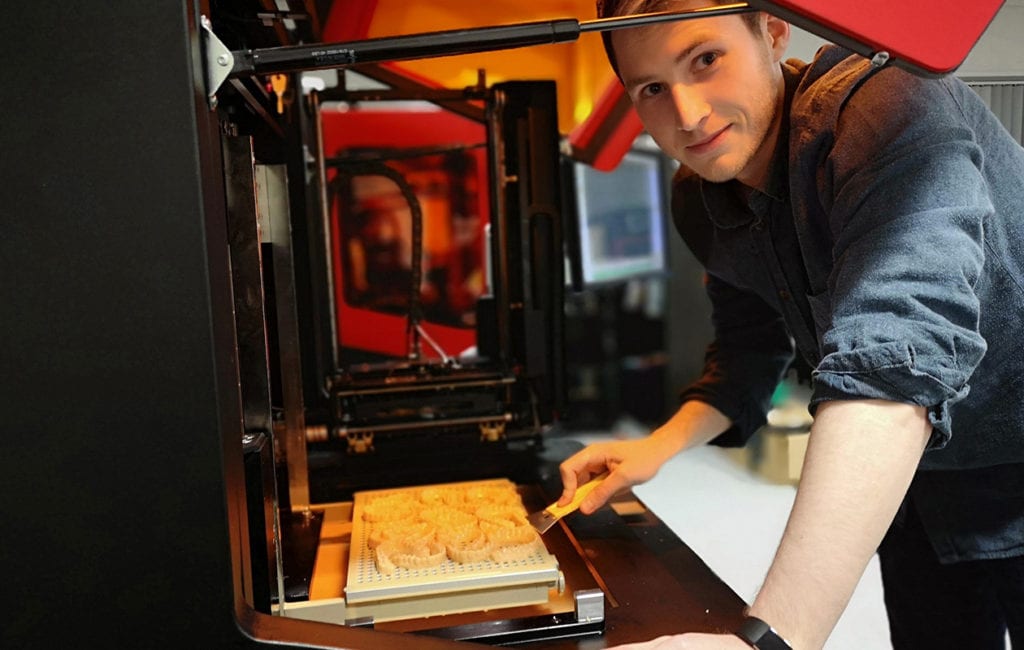

After consideration the brothers settled on an EnvisionTEC Vector 3SP with E-Model Peach material. The Vector uses patented technology to ensure a superior surface quality and accuracy across a large build area. The price of the machine was very competitive compared to larger models from rivals, and allowed for the high speed production of a large number of models simultaneously.

“We opted for EnvisionTECs Vector 3SP because of the quality of prints, its price and its size, which provides the ability to print a large number of dental models per print at high speed.” - Louis Monte, Director, 3D Printed Dental Models

The business got off to an swift start, with the team experiencing huge demand for its services. So much so that it had to both move to a bigger premises and invest in a second Vector printer. The Vector 3SP printers are in constant use but have stayed reliable. The brothers and their team can rely on the printers to run jobs successfully time after time, even leaving them to run prints overnight, knowing that when they return they will be completed ready for customers.

EnvisionTEC and its partner AM3D provide the 3D Printed Dental Models team with support and are on hand when required to give advice and keep the business moving.

The Future.

Having worked closely with dentists and orthodontists across the UK, the brothers now have an even better understanding of the industry and gaps in the market. The aim is to fill these gaps and widen their manufacturing to include even more products. The investment in EnvisionTEC and its huge range of printers and dental materials ensures that they can, in the future easily move between applications and meet the needs of their customers.

“Due to the quality and accuracy of the models created on the EnvisionTEC printers, as well as the high level of service EnvisionTEC provide, I would definitely recommend them.” - Louis Monte, Director, 3D Printed Dental Models

Partners

Thanks go to UK distribution partner AM3D for their support in the making of this case study (http://am3d.co.uk/)

Thanks go to UK distribution partner AM3D for their support in the making of this case study (http://am3d.co.uk/)

“EnvisionTEC provides great after care and are always at the end of the phone. If there are any issues they are quickly dealt with which is really important to us as we have customers needing our product. So to have a machine out of action would really damage us.” - Louis Monte, Director, 3D Printed Dental Models