French Bureau Chooses EnvisionTEC Printers and Materials to Enhance its Offerings

Do’in3D was established in September 2014 and provides bureau printing services to companies across France.

The company workshops and offices, located in Le Bourget-du-Lac provide a range of prototype manufacturing services together with small series parts and design mock-ups. Its consultancy services match the needs of the customers with the correct technology to meet their individual requirements. Do’in3D provides scanning facilities and a large range of printing technologies to meet the needs of its customers.

“We were looking for a 3D printer capable of producing larger parts, with exceptional surface quality. It had to be a medium-sized machine based on liquid resin.”- Stephane Chat , CEO, Do’in3D

Why look at 3D printing?

Since the millennium, the Do’in3D team watched industry trends, and saw the rise in the adoption of additive manufacturing technology. They watched as its use was rapidly expanded into prototyping across a range of industries.

Do’in3D was established based on this demand, and a need to provide outsourced 3D printing and production services to individuals and businesses. At the time of its inception and in the years that followed it became clear that different companies needed different technologies to achieve their results. To this end Do’in3D invested in a variety of machines to allow for their needs to be met.

“The EnvisionTEC Ultra completes our portfolio of technologies, providing clients with the ability to print large objects, and multiple smaller objects at outstanding resolutions.” – Stephane Chat, CEO, Do’in3D

Why EnvisionTEC?

Though Do’in3D had invested in a number of technologies including FDM, PolyJet, ColorJet, Multi Jet Fusion and even SLS machines, one technology the company did not have was a high quality polymer based solution. This left a gap in their customer offering.

Do’in3D was aware of EnvisionTEC and the quality available from its DLP and 3SP series of printers. Having experienced the surface quality available and seen the extensive portfolio of case studies, the team engaged with EnvisionTEC and were passed to local distribution partner ARKETYP3D.

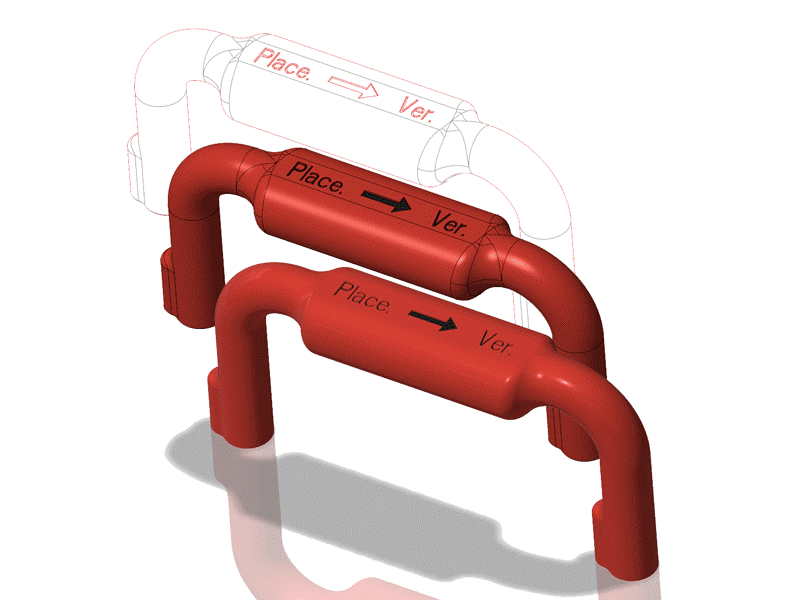

ARKETYP3D engaged with Do’in3D and demonstrated a number of models within the EnvisionTEC range, from smaller desktop models through to large frame 3SP machines. Following these demonstrations and seeing a number of materials to suit the needs of it’s customers, including E-OrthoShape and E-RigidForm, Do’in3D settled on an Ultra 3SP model.

EnvisionTEC, the perfect choice for manufacturing…anything.

EnvisionTEC offers a full range of desktop, full-production and high-speed continuous 3D printers for a variety of industries including: manufacturing (jewelry, aerospace, automotive, consumer goods), medical , dental/orthodontic, audiology and even biotechnology.

Whether you are looking for faster, more accurate prototypes for design verification and testing or for real mass production of custom products, EnvisionTEC can help.

Partners

Thanks go to French distribution partner ARKETYP3D for their support in the making of this case study.

Télécharger en français

Le service Bureau Do’In3D choisit les imprimantes EnvisionTEC pour améliorer son offre