SSK Dental

Our Experience

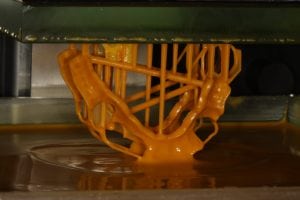

SSK Dental Technik is a dental lab in Germany that produces crowns, bridges, dentures and drill guides using the PixCera and the new Perfactory® Digital Dental Printer.

SSK Dental has been working with EnvisionTEC 3D printers since January 2009. The lab uses both the Perfactory DDP and the desktop system PixCera to produce models from 3D designs both quickly and accurately.

Investing in 3D

Prior to purchase, Sokalla researched other 3D printing manufacturers. Sokalla was not initially certain about bringing EnvisionTEC machinery to the lab, but time has proven he made the right choice.Bearbeitung-Beispiel-fotogen-gkIMG_0247 klein

“The decision was not easy for me to make a large investment,” he said. “However, after more than 5 years of work with these printers we have learned to appreciate the easy handling and the good results.” Another EnvisionTEC 3D printer may be in store for SSK. Says Sokalla, “I would make this decision from today’s perspective and experience again.”

“The decision was not easy for me to make a large investment,” he said. “However, after more than 5 years of work with these printers we have learned to appreciate the easy handling and the good results.” Another EnvisionTEC 3D printer may be in store for SSK. Says Sokalla, “I would make this decision from today’s perspective and experience again.”

Integrating EnvisionTEC

The lab intended both the Perfactory DDP and the PixCera to increase speed and accuracy in production. Both machines were quickly integrated into everday work. Sokalla attests that the 3D printers as well as the Perfactory RP software are easy to use, and his employees learned quickly to produce high-quality results with the two printers.

SSK Dental smoothly introduced the EnvisionTEC systems to their lab work. With an EnvisionTEC 3D printer, material changes are efficient, without changing used basements or resin reservoirs. Sokalla and his technicians find that switching materials for different applications requires little effort.

In addition to the everyday work of a dental laboratory, SSK Dental also experiments with various softwares and materials. The lab uses the EnvisionTEC 3D printers to experiment with new processes for several applications, including implant prosthetics.

Digital Drill Guides

“The material supply, the simple handling of the software and the price range made it crucial for me to acquire the Perfactory DDP.”

When the Perfactory DDP system hit the market, SSK Dental decided relatively quickly to bring the machine into their work process. Sokalla reasoned that the printer is easy to use, quickly created prints, and was impressed by the good fit of the drill guides the 3D printer creates.

“Particularly impressive is the variety of materials, the quick easy change of material and also the almost loss-free exchange of the materials,” said Sokalla.

Working continuously the DDP 3D printer achieves 60 units in 3.5 hours for crowns and bridges, or up to 5 model castings in 5 to 6 hours. Sokalla says about 300 to 400 units of crowns or bridge work could be made in 24 hours. “You could also go faster,” he notes, and estimates that the machine could build as much as 500 units per day should he ever have a need for it. Depending on the size and arrangement of the building platform, he estimated SSK Dental achieves about 20 model castings each day.

Superior Service

SSK Dental has received excellent service and support from EnvisionTEC. Lab employees can carry out small maintenance like lamp replacement or calibration themselves, while more difficult repairs are handled through phone and email tech support, as well as instructional videos.

The few problems SSK Dental has had were addressed and quickly eliminated. Sokalla stated that even the process of adjusting build parameters is typically “carried out immediately,” so that SSK Dental can use their facilities without significant disruption:

“With the support, and expertise of the EnvisionTEC staff, we are very satisfied.”