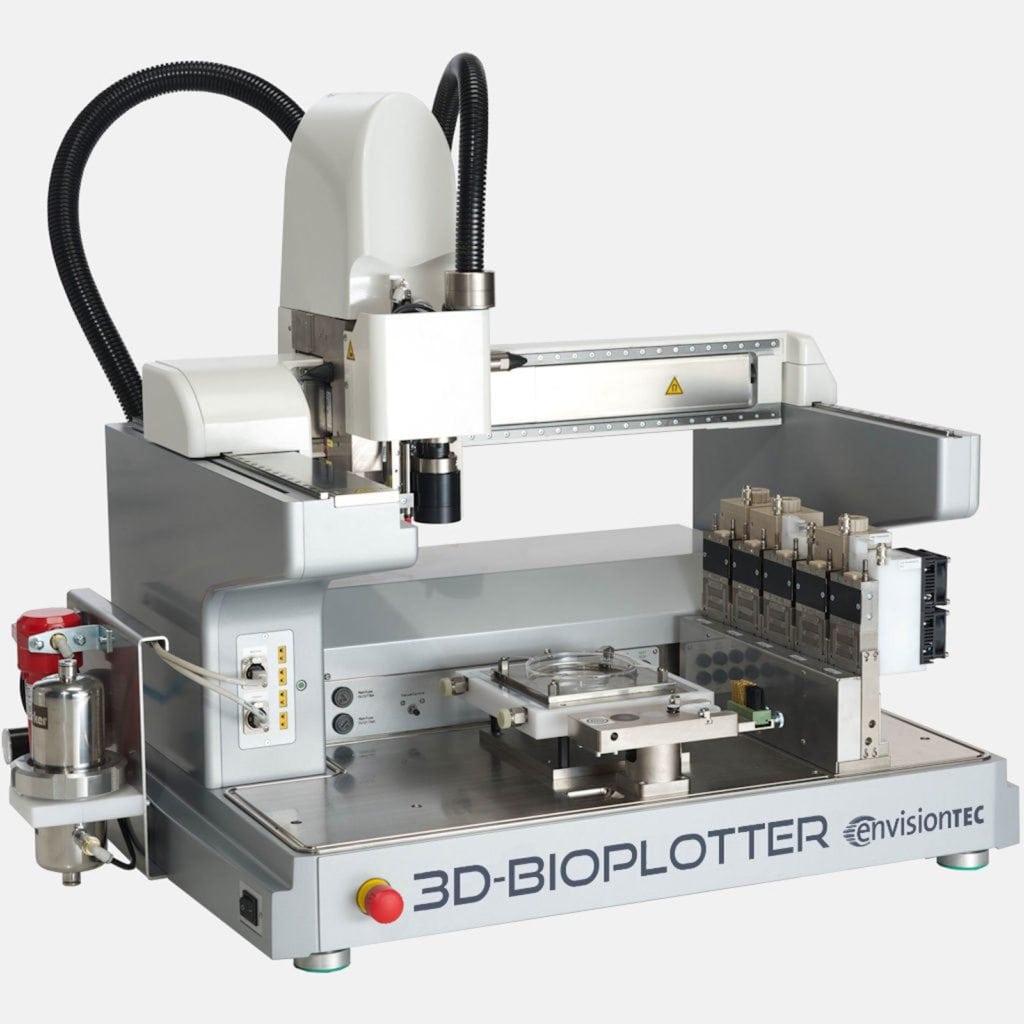

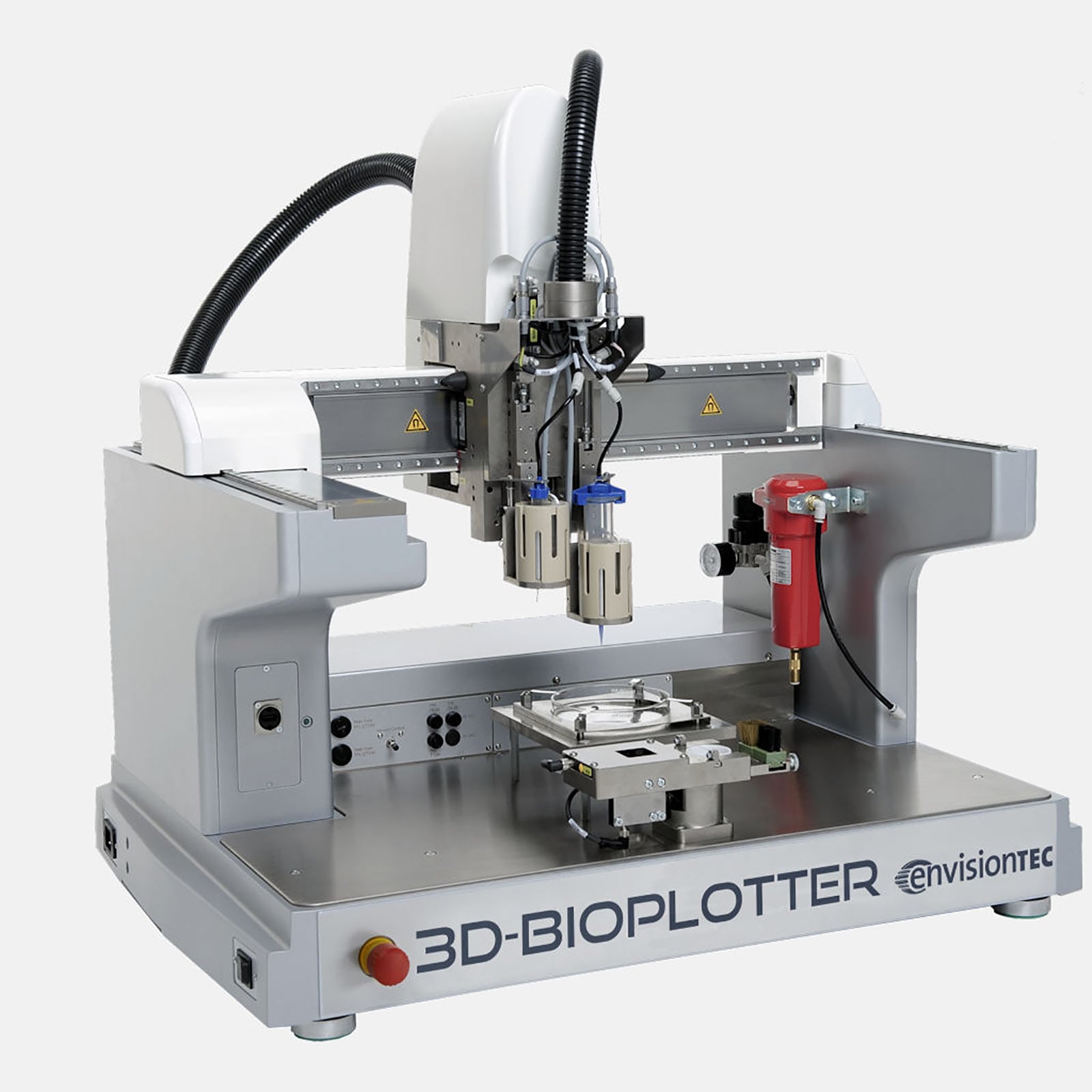

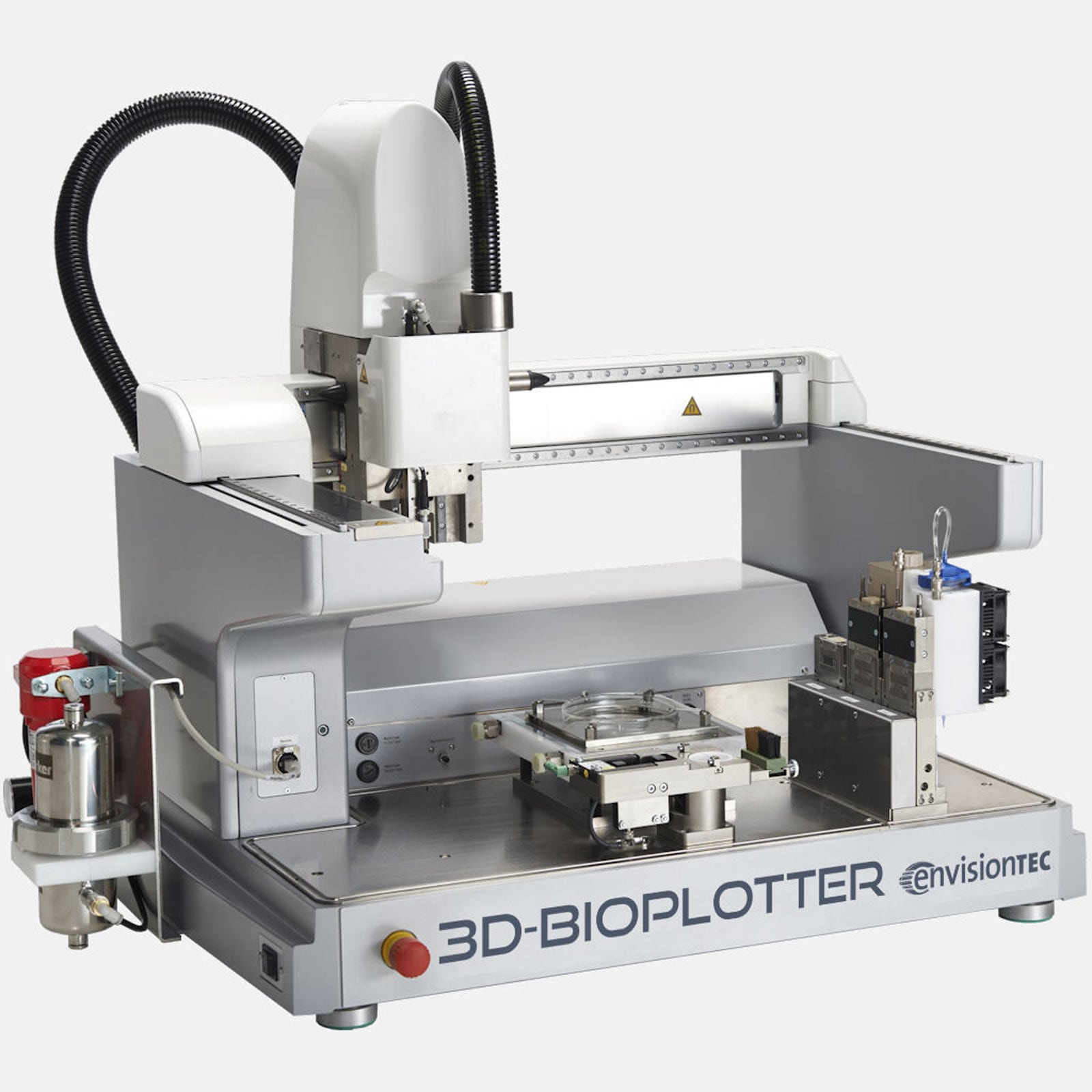

The 3D-Bioplotter System is a versatile rapid prototyping tool for processing a great variety of biomaterials for computer-aided tissue engineering (CATE), from 3D CAD models and patient CT data to the physical 3D scaffold with a designed and defined outer form and an open inner structure.

- Built-in camera to enhance needle calibration and to ensure consistent prints

- Temperature controlled build platform and sensor ports. This allows greater material variety and finely tuned environments for low tolerance scaffolding.

- Five cartridges slots for more materials in a single print.

Machine Properties

Filters Included

Sterile and Particle

Platform Temperature Control

Yes (Chiller Included): -10° – 80°C (15° – 176° F)

Max Heads

5

Head Temperature Range

Low: 0° – 70°C (32° – 158°F) or High: 30° – 250°C (86° – 482°F)

No. of Heads Included

2

Tool Changer Type

Modular Tool Changer

Cartridge Sizes

10 – 30 ml (.3 – 1.0 fl oz)

Other Usable Modules

All

Platform Height Control

Automatic

Needle Calibration

Camera

Material Calibration

Semi-automatic

External Temp. Ports

4

Included PC

Professional PC

Build Volume (XYZ)

150 x 150 x 150 mm (5.91 x 5.91 x 5.51 in.)

Speed

0.1 – 150 mm/s (0.004 – 5.91 in/s)

Minimum Strand Diameter

0.100 mm (0.004 in.) Material Dependent

Axis Resolution (XYZ)

0.001 mm (0.00004 in.)

System Properties

- A new user management allows users to both share projects, materials and patterns, as well as have their own separate set of files for improved overview and security.

- Input of outer shapes through STL files

- Multi-part and multi-material capable through the use of an automatic tool changer and multiple print heads.

- Generation of volume support structures for complex shapes.

- Database of inner patterns (user-editable) in the controlling software, avoiding requiring patterns in the STL files.

- Complex inner pattern with straight lines, zig-zag shapes and wave forms as well as hexagon shapes, including shift functions for “in between the lines”printing

- Database of materials (user-editable) with all process parameters.

- Material life time control to avoid scaffold fabrication with degraded materials.

- Complete control of all printing parameters (temperature, pressure, speed, etc) through the software.

- Photographic log of the full platform for each layer available for verification of error-free object interior after printing.

- Mid-print measurement of strand dimensions using the built-in camera.

- Automatic platform height control for petri dishes, well plates, as well as other printing surfaces.

- Improved surface finish of fabricated parts using randomized start position in outer contours.

- 2D Dot-Printing (Biopatterning) capability

- Individual temperature control of each printing head, both in the parking positions, as well as during printing

- Low-Temperature Print Head: 0° – 70°C (32° – 158°F) with disposable PE cartridges.

- High-Temperature Print Head: 30° – 250°C (86° – 482°F) with reusable stainless steel cartridges.

- UV Curing Head (365 nm).

- Needle cleaning station, with automatic cleaning before and during the print project available.

- Luer Lock needle tips, 0.1mm to 1.0mm inner diameter available.

- Automatic recalibration of park position coordinates in extensively used 3D-Bioplotters.

- LOG file creation after project completion with all relevant data.

- Footprint (L x W x H): 976 x 623 x 773 mm (38.4 x 24.5 x 30.4 in.)

- Weight: About 130 kg (286 lbs)

Materials Available

A versatile medical-grade silicone that 3D prints objects with medium hardness

A versatile thermoplastic materials for tissue engineering applications

A versatile thermoplastic materials for tissue engineering applications

A versatile technical-grade silicone that 3D prints objects with medium hardness

A versatile thermoplastic materials for tissue engineering applications

A cellulose derivative for 3D printing sacrificial supports at high temperatures

A cellulose derivative for 3D printing sacrificial supports at low temperatures

Applications

Related Printers:

3D-Bioplotter® Starter Series

Der 3D-Bioplotter Starter Series wurde für neue Forschungsgruppen im Bereich Tissue Engineering entwickelt, die wenige Anforderungen bezüglich multiple parallele Materialverarbeitung und Automatisierung haben. Es besteht aus derselben Basis-Hardware und Software wie die anderen zwei 3D-Bioplotter Modelle, jedoch ohne modulares Design und Temperaturkontrolle der Plattform. Der 3D-Bioplotter Starter Series wird mit 2 fest montierten Hochtemperaturköpfen geliefert.

3D-Bioplotter® Developer Series

Der 3D-Bioplotter Developer Series wurde für neue Forschungsgruppen im Bereich Tissue Engineering entwickelt, sowie spezialisierte Anwender, deren Anforderungen durch die limitierten Fähigkeiten dieser Maschine noch abgedeckt werden. Es besteht aus derselben Basis-Hardware und Software wie der 3D-Bioplotter Manufacturer Series, jedoch ohne Kamera, sowie eine niedrigere Anzahl an Parkpositionen beim Werkzeugwechsel.

Eingebaute Filter

Particle and Sterile

Temperaturkontrolle der Plattform

Yes (Chiller not included): -10° - 80°C (14° - 176°F)

Primärmarkt

Materials Available for the 3D-Bioplotter® Manufacturer Series Printer

Medical grade Polycaprolactone (PCL) is a biodegradable thermoplastic polyester that is processed at high temperatures. It is suitable for both short-term and long-term use in the body (longer than 29 days) and ideal for applications such as bone regeneration, cartilage regeneration, drug release and hybrid scaffolds.

![]()

Medical grade Polycaprolactone (PCL) is a biodegradable thermoplastic polyester that is processed at high temperatures. It is suitable for both short-term and long-term use in the body (longer than 29 days) and ideal for applications such as bone regeneration, cartilage regeneration, drug release and hybrid scaffolds.

![]()

This sugar derivative can easily be processed as a melt in prolonged jobs with no measurable degradation. The material is biocompatible and cell friendly, ensuring that residue material does not negatively affect the final object’s biological properties.

![]()

LT Support RG can easily be processed as a hydrogel in short to medium long jobs. The material is biocompatible and cell friendly, ensuring that residue materials do not negatively affect the final object's biological properties.

![]()

Polycaprolactone (PCL) is one of the most versatile thermoplastic materials for Tissue Engineering Applications. With little thermal degradation, it is an excellent material for large, time-consuming parts.

![]()

This very versatile material can be used for numerous demo applications: from trying out new shapes and patterns using a cheap material; through making technical parts (e.g. gaskets); to medical device casings

![]()

Silicone 60A UV MG is a biocompatible, bio-inert, non-biodegradable liquid silicone rubber that is cured with a UV light and delivers a Shore A hardness of 60. A transparent material, it can also be mixed with pigments. Approved only for short-term use in the body (29 days or less), it is suitable for microfluidics, wound dressings, bio-sensor housings, and prototyping.

![]()