In this paper, learn the difference between SLA, DLP and 3SP for additive manufacturing in a large build envelope when high accuracy, repeatability, reliability and throughput are required.

In this paper, learn the difference between SLA, DLP and 3SP for additive manufacturing in a large build envelope when high accuracy, repeatability, reliability and throughput are required.

SLA has inherent difficulties building large parts that are expensive to correct with galvo mirrors, optical systems and multiple laser systems.

See why DLP and a new method called 3SP offer more economical solutions that are also faster for production.

Manufacturers who require large build envelopes, for large parts or a series of smaller parts, are adopting 3SP rapidly as a replacement for expensive SLA systems.

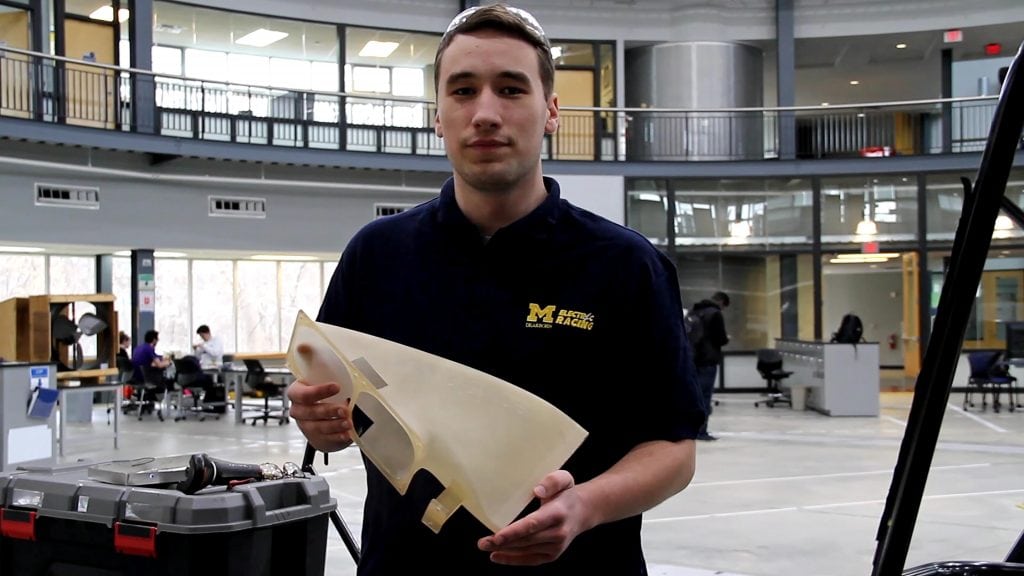

See How UM-Dearborn Students Use 3SP in Electric Car Project

Download Now

By downloading this case study, you’ll be added to our additive manufacturing list and agree to be contacted by our sales team in regards to your requirements.