These EnvisionTEC materials are for the company’s line of high-speed continuous 3D printers.

High flexural modulus and strength in a hydrophobic material that produces super tough parts, with nearly 4x the impact resistance as most engineering plastics.

![]()

![]()

![]()

Create strong, stiff parts with excellent high heat resistance, including wind tunnel models for aerospace and automotive applications, as well as rapid tooling for injection molding.

![]()

Stiffness combined with toughness make this material ideal for use in a wide variety of impact-resistant medical devices.

![]()

![]()

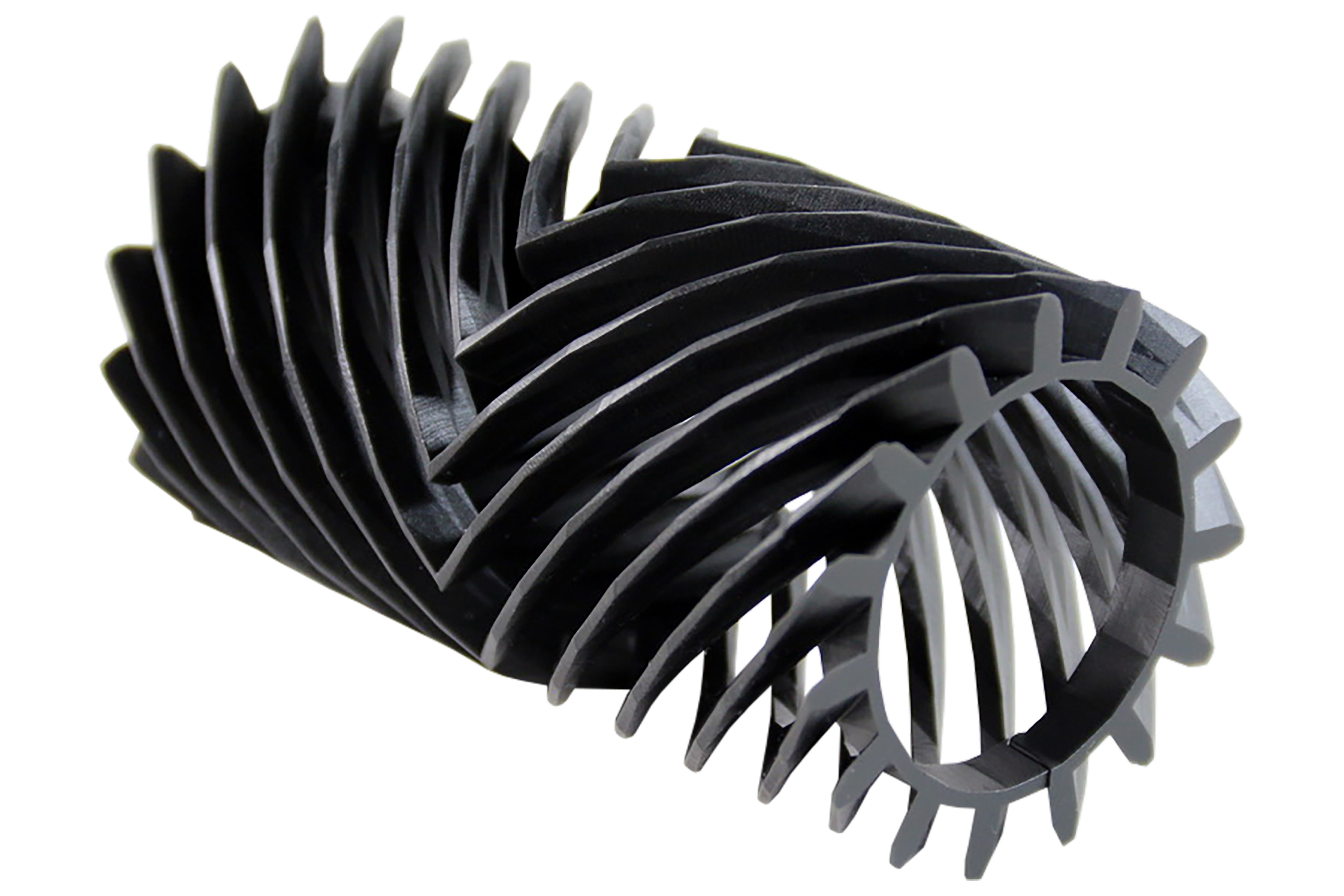

EnvisionTEC's Rubber Elastomer E-RE70 is an elastomeric material with a tough rubber-like performance.

![]()

![]()

![]()

![]()

EnvisionTEC's E-RE90 is an elastomeric material with a tough, rubber-like performance, allowing for the 3D printing of parts previously made from technical foams, rubbers, or polyurethanes.

![]()

![]()

![]()

![]()

![]()

Loctite E-IND402 is an elastomeric UV photocurable resin that exhibits high resilience while maintaining excellent tensile strength. It is a single component system with excellent green strength and does not require thermal post processing.

![]()

![]()

![]()

![]()

Loctite E-3955 FST HH is a high performance, high modulus product which boasts excellent flexural and tensile physical properties with outstanding flame retardance.

![]()

![]()

![]()

![]()

KeySplint Soft for EnvisionTEC is a a 3D printing resin ideal for printing splints and night guards.

![]()

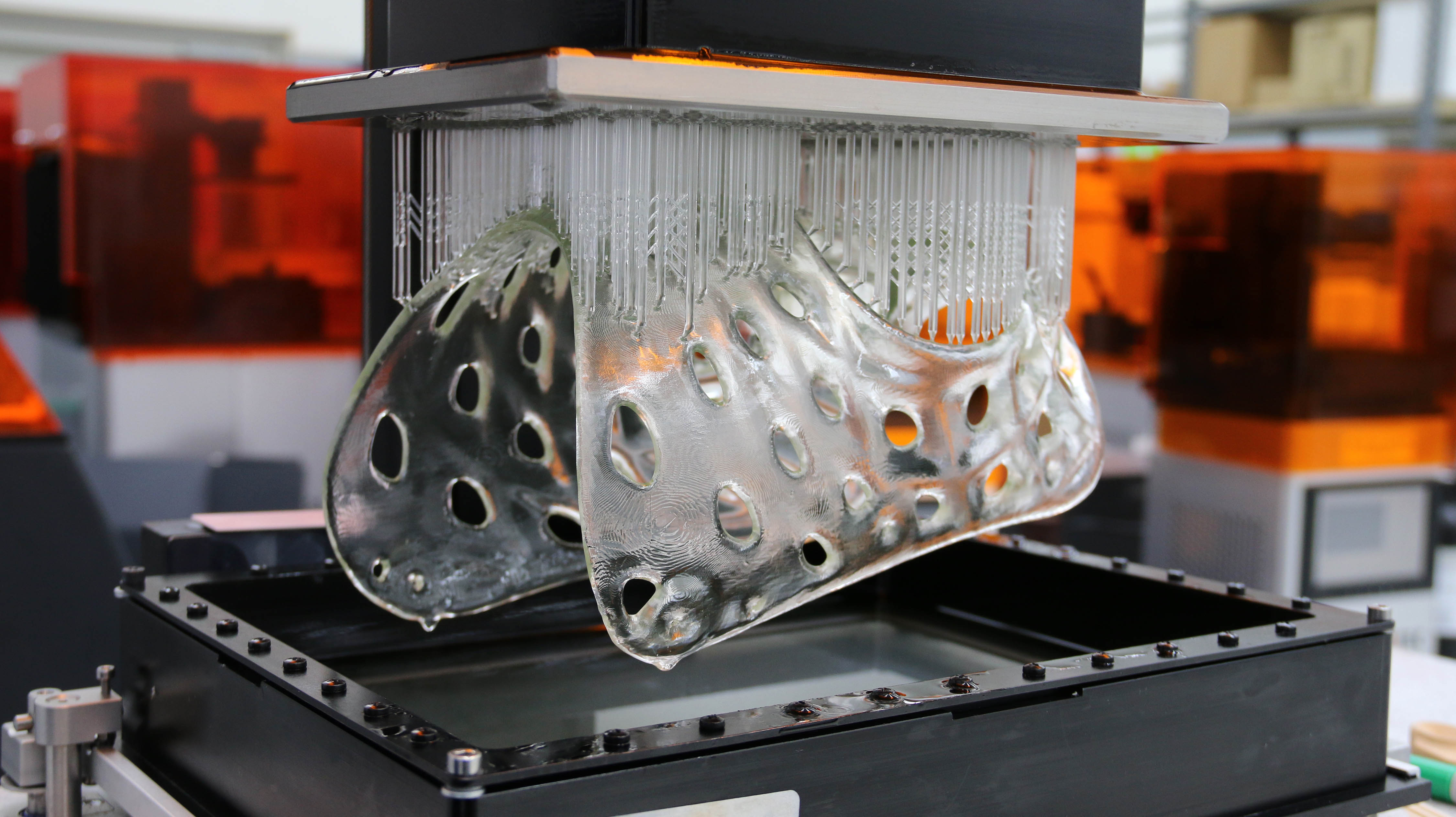

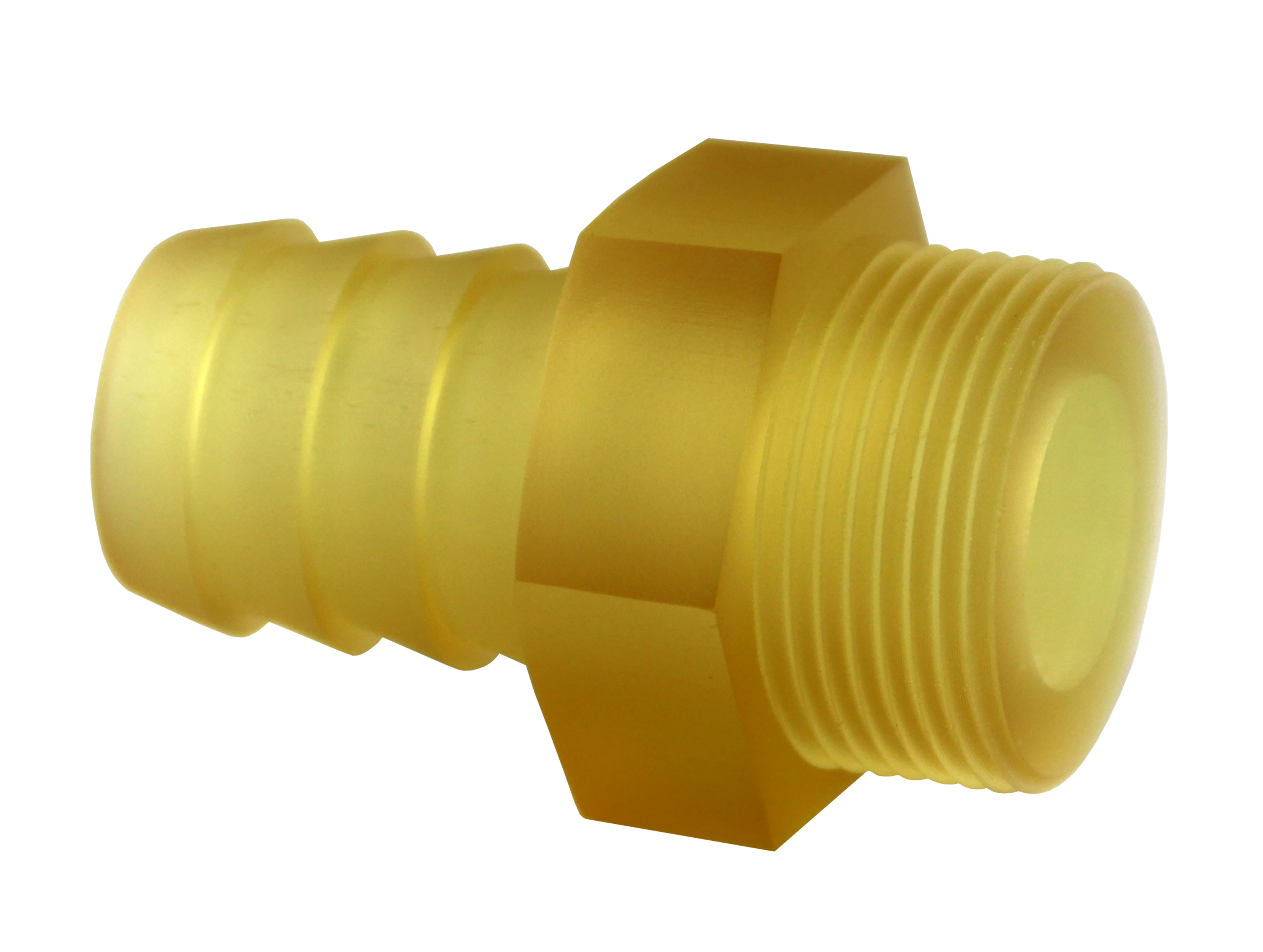

E-Aquasol is a water-soluble 3D printing resin, allowsing industrial manufacturers to shell-cast thin-walled parts with high feature resolution.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

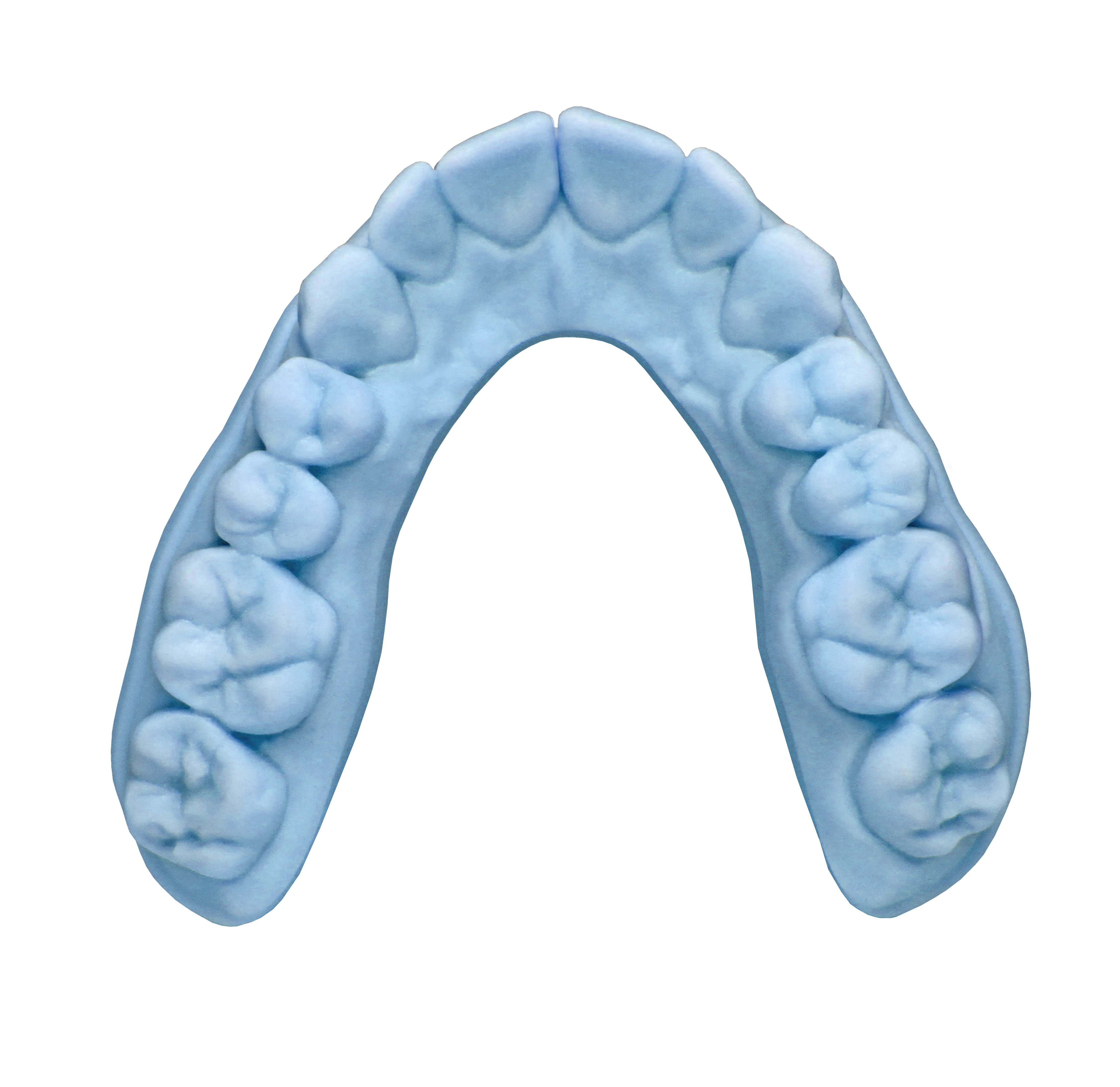

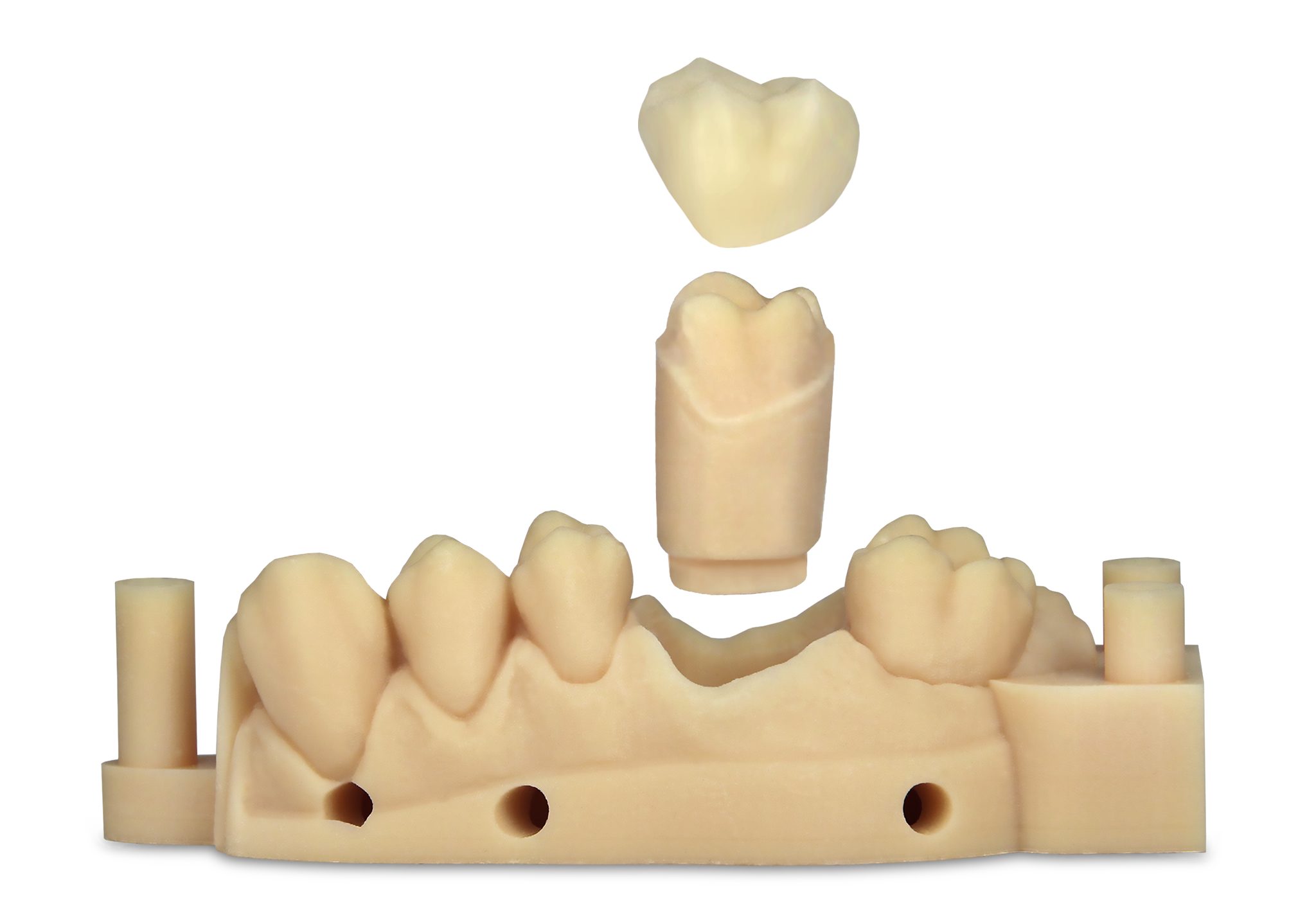

E-Model HS is a high speed 3D printing material for use in producing orthodontic arch models extremely quickly on EnvisionTEC cDLM 3D printers.

![]()

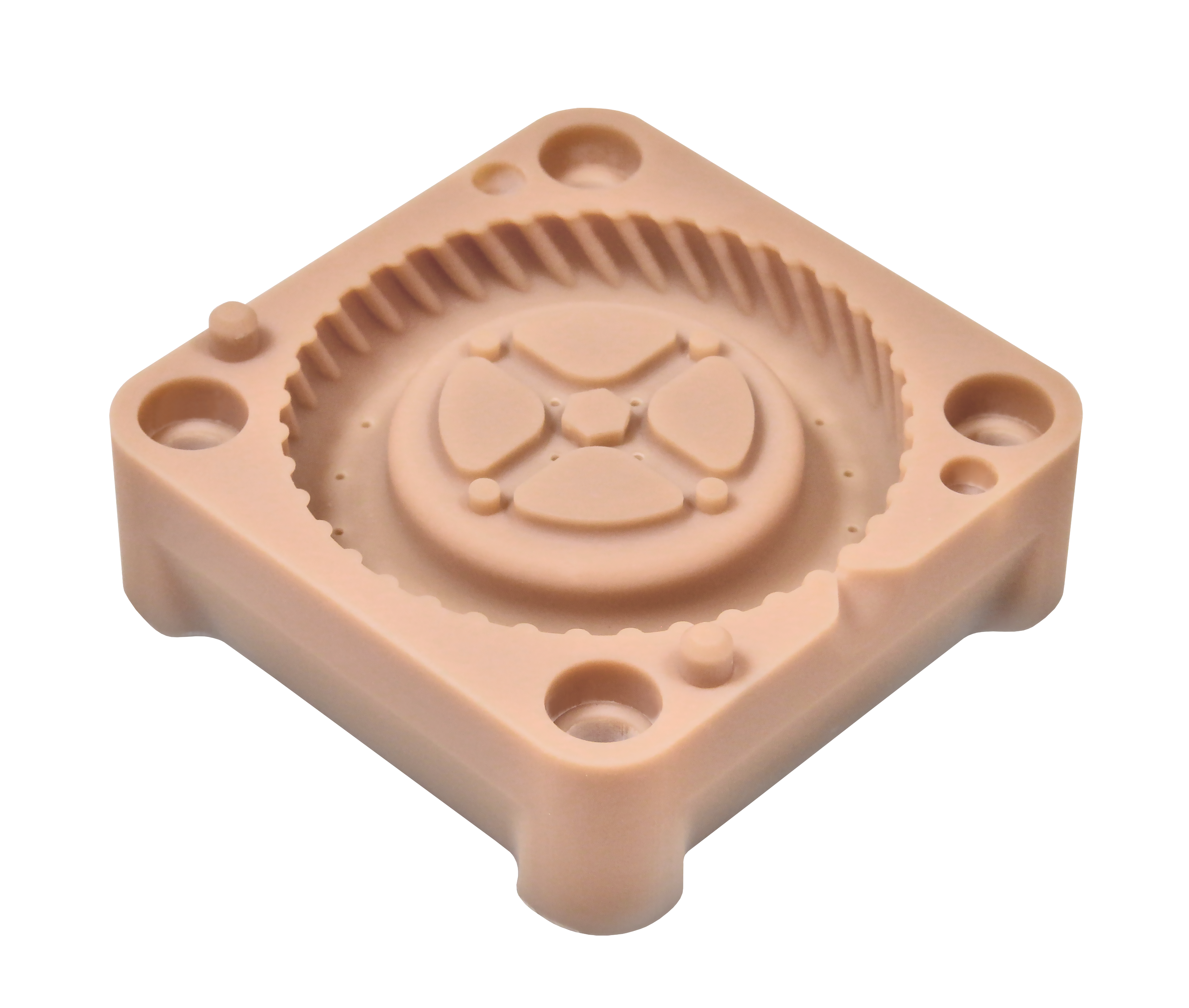

EnvisionTEC’s E-Mould provides a new solution for injection molding with a validated process chain.

![]()

![]()

![]()

![]()

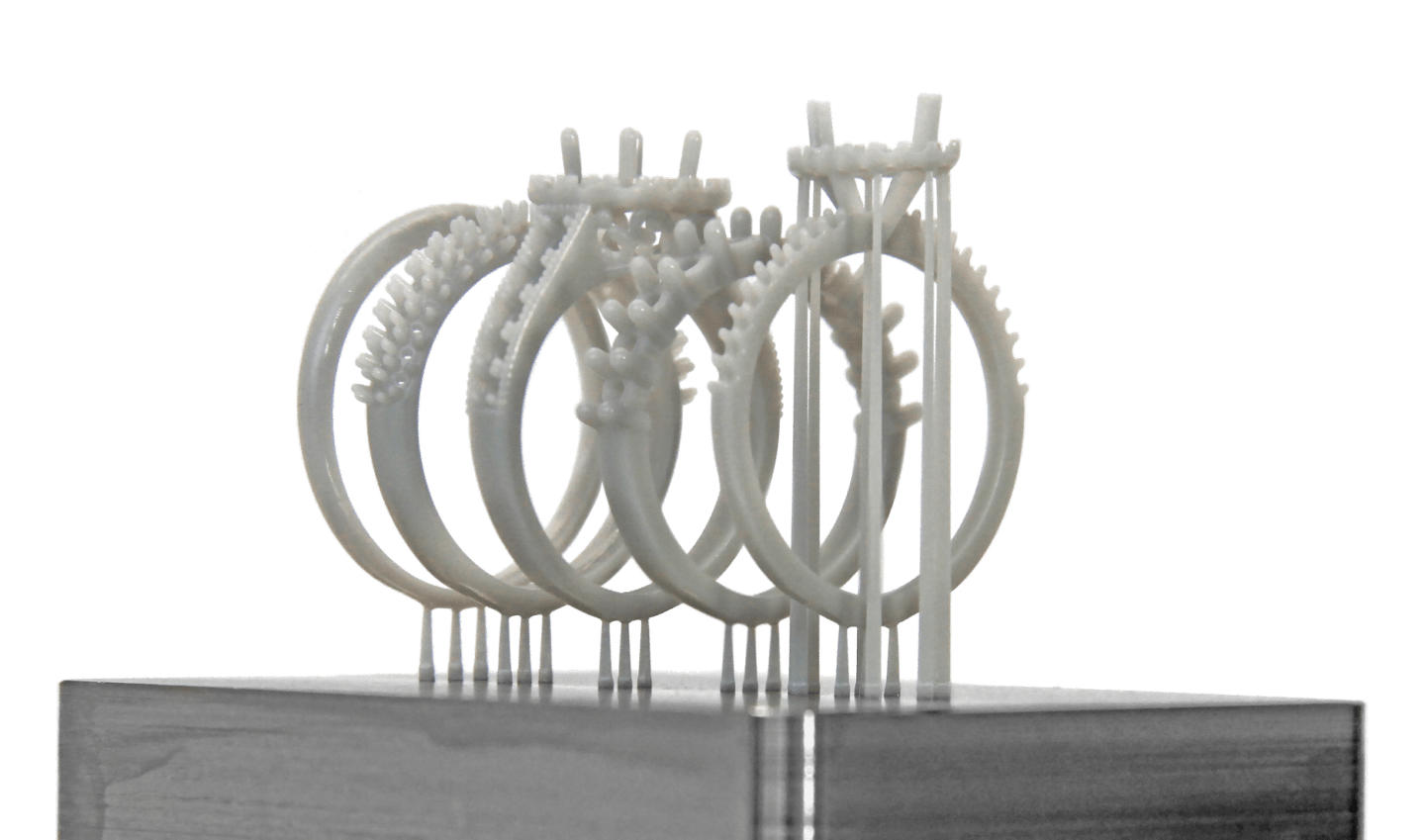

A breakthrough material for the high-speed printing of a castable photopolymer with the highest wax content available in 3D printing.

![]()

A popular production casting material, PIC 100 is ideal for printing jewelry, dental and other parts requiring exceptional detail and surface finish. In jewelry, PIC is recommended for pieces up to 5 grams finish weight, such as bridal jewelry.

![]()

![]()

![]()

![]()

![]()

E-Tray is a 3D printing material for use in producing individual customized impression trays.

![]()

NextDent Gingiva Mask is a flexible material that can be used in combination with a model material. This makes it possible to print parts of the model that need a certain flexibility, such as Gingiva Masks on implant models.

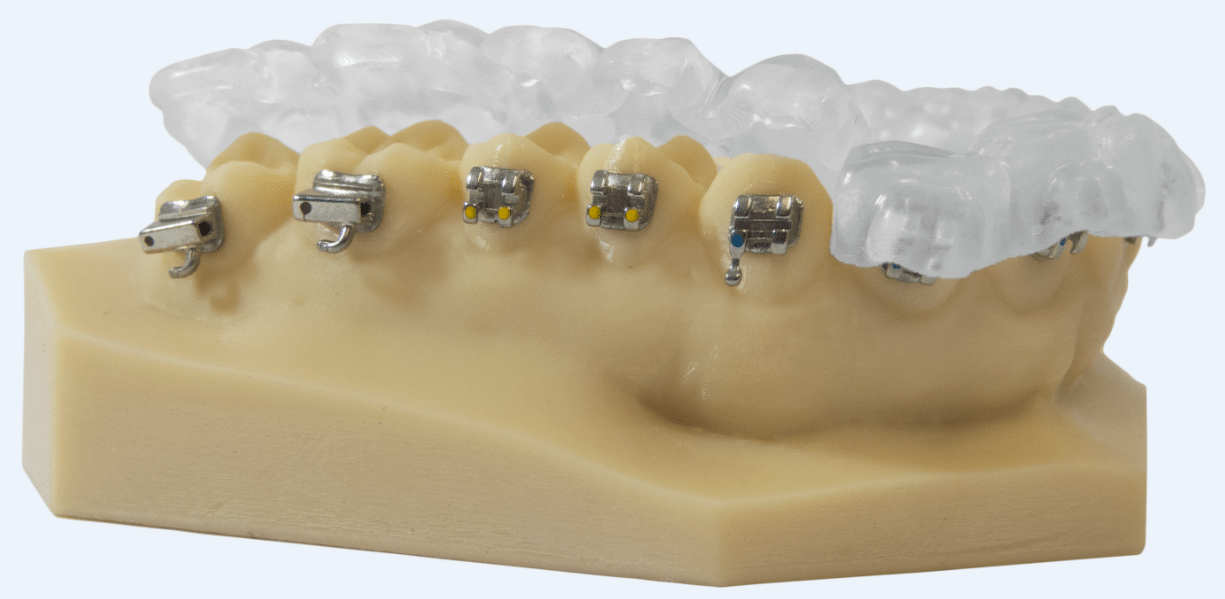

NextDent Indirect Bonding Tray is a biocompatible Class I material for orthodontic applications.

![]()

E-Model Beige printing material for DLP and cDLM 3D printers is the perfect choice for orthodontic models for thermoforming aligners over.

![]()

E-Model Light DLP printing material for DLP and cDLM 3D printers is the perfect choice for a wide variety of high-accuracy dental modeling needs.

EnvisionTEC’s E-Guide is a biocompatible certified Class I material, developed for the production of high precision surgical drill guides for use in implant surgery. The results produced by combining E-Guide with EnvisionTEC technology are superior to traditional methods of manufacturing implant placement guides.

E-Guard is a biocompatible transparent material for the production of accurate orthodontic bite splints and night guards. The results produced by combining E-Guard with EnvisionTEC technology are superior to traditional methods of manufacturing bite guards and night guards. It is a clear material, allowing for maximum visibility.

![]()

EnvisionTEC’s quick building QView resin is ideal for providing fast design verification models. This exciting new material is capable of impressive print speeds for the full build envelope. This allows designers to put their custom design pieces into their customers’ hands in record time for final fit and design verification. It can also be used as a pattern when built in high resolution to make a silicone mold.

![]()

![]()

![]()

R5-385 material is an update on the original R5 material, one of EnvisionTEC's earliest materials still in use around the world, re-engineered for optimal performance in 3D printers utilizing 385nm wavelength light sources.

![]()

![]()

![]()

![]()

![]()

![]()