Calibrated in Detroit —

In many ways, EnvisionTEC was born out of the U.S. automotive industry. Company founder and CEO, Al Siblani, an engineer, began his career in the 3D printing industry placing the first Helisys lamination machines at Ford, GM and Chrysler before coming up with an idea for a better 3D printer using DLP technology in the late 1990s.

Today, EnvisionTEC’s headquarters remains in Detroit — in a former Ford Motor Co. building based in Dearborn, actually — and the company continues to enjoy close ties with automotive OEM and suppliers worldwide.

Today, EnvisionTEC’s headquarters remains in Detroit — in a former Ford Motor Co. building based in Dearborn, actually — and the company continues to enjoy close ties with automotive OEM and suppliers worldwide.

Part of the reason that relationship continues is because EnvisionTEC has dedicated itself to developing new 3D printers and materials that are heat-resistant, impact-resistant, capable of being used in injection molding, flexible enough for snap-fit applications and just plain durable.

Bill Schroer, who retired from Ford Motor Co. after 30 years, is a top engineer at EnvisionTEC.

EnvisionTEC also employs many engineers who previously worked directly in the automotive industry, who are constantly advocating for the needs of the sector. In fact, our seasoned engineering team in Dearborn has more than 60 combined years of experience working directly for OEMs in Metro Detroit.

That’s why automotive companies continue to use our 3D printers and materials for prototypes, design verification, auto show parts, jigs, fixtures, fasteners, molds and more.

Why do automotive customers love our technology? EnvisionTEC’s smooth, accurate 3D builds mean little to no hand finishing. What’s more, our industrial machines are affordable to operate and maintain, incredibly reliable and backed by outstanding support.

Breakthrough Material Development

In 2017, EnvisionTEC is launching E-Model, a breakthrough material for the automotive, aerospace and general manufacturing market. Its low viscosity means that the material is highly flexible and can handle thin-walled projects up the biggest, bulky parts. E-Model, which is available in five colors, is also so accurate — and stays so true through curing — that our dental customers use it for precision model work.

3D Printers for the Automotive Industry

The D4K PRO Industrial is built on the most reliable 4K UV DLP projector and includes EnvisionTEC's patented PSA for low separation forces. Brought to you by the original inventors of DLP 3D printing technology.

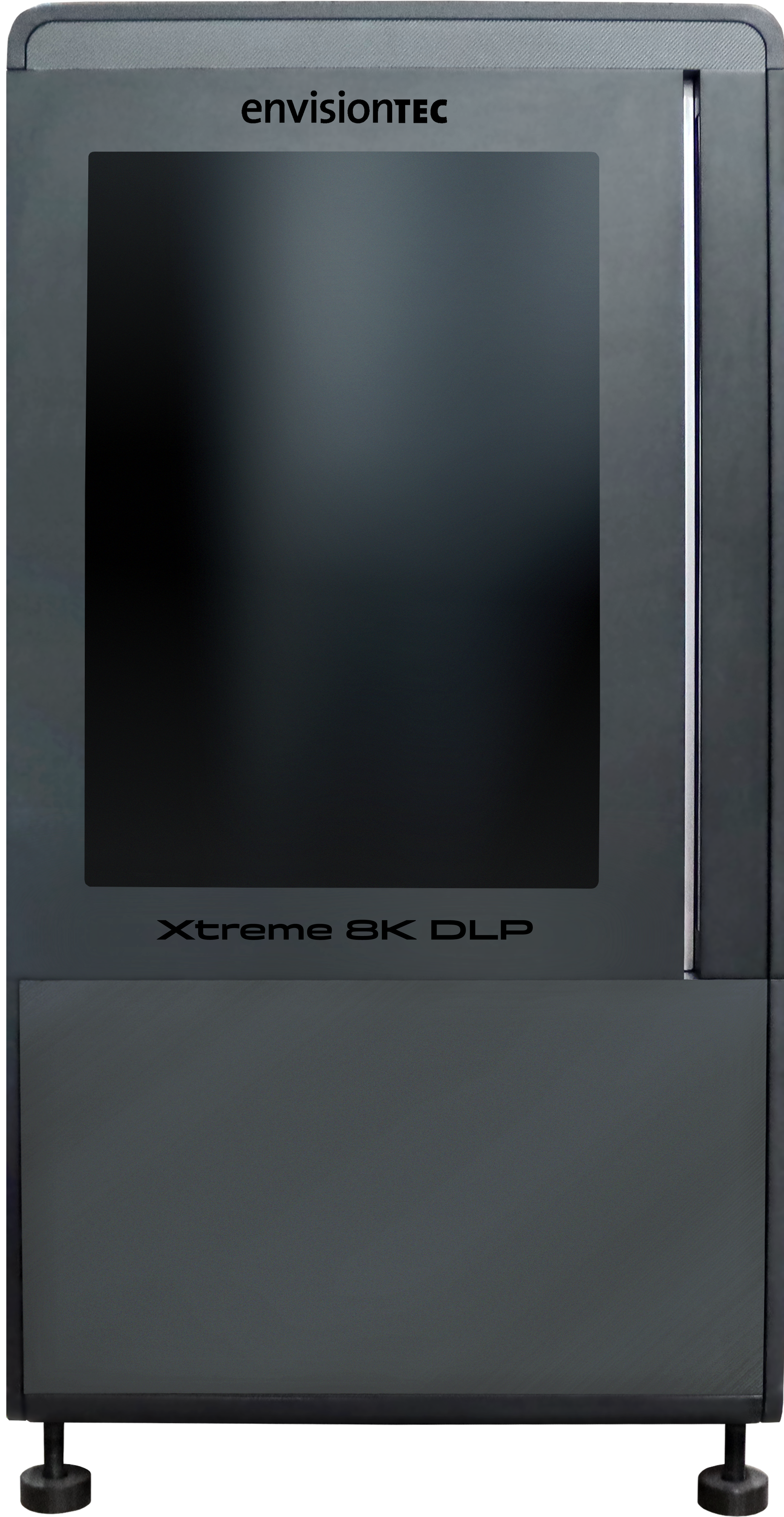

The Xtreme 8K DLP uses dual 4K projector DLP technology to quickly 3D print highly accurate parts from STL files regardless of geometric complexity. With a large selection of materials, you will be able to produce high-quality end-use parts for a variety of applications, including industrial and medical items. A heated material vat allows for additional materials with highly desirable properties.

Perfect for a wide variety of 3D printing applications, the Envision One cDLM is capable of printing up to 45 mm/hour, material dependant.

The ULTRA 3SP HD provides the same excellent surface finish and speed as the original ULTRA 3SP, but adds an incredible 50 µm (0.002 in.) resolution capability to your builds.

Introducing the only DLP-based 3D printers utilizing a true 4M pixel projector with UV optics tuned to 385nm wavelength. The P4K Series delivers the highest accuracy coupled with the highest finished product functionality. Utilizing Artificial Intelligence (AI) in pixel tuning to deliver extremely high quality surface finish, the P4K delivers next generation advanced DLP technology in 3D printing.

The Vector 3SP provides excellent surface finish and speed with a build size of up to 30,316 cubic cm (1850 cubic in.) to produce everything from concept models to functional parts in 100 µm (0.004 in.) resolution.

The Vector HD 3SP is ideal for those who need large parts up to 30,316 cubic cm (1850 cubic in.) with a resolution of 50.8 µm (0.002 in.). High detail parts with smooth surface finishes make the Vector HD 3SP an ideal option for a wide variety of applications.

EnvisionTEC's largest 3SP option, the Xede 3SP produces excellent prototype and production parts with a build area up to 95,045 cubic cm (5800 cubic in.) and a resolution of 100 µm (0.004 in.).

A great manufacturing option for a wide variety of consumer and automotive applications, the ULTRA 3SP provides 100 µm (0.004 in.) resolution and a build size of up to 9013 cubic cm (550 cubic in).

3D Printing Materials for the Automotive Industry

Loctite E-5015 is a one-component, light-cure silicone resin with high durability and flexibility. It offers high resolution printing of shore A70 silicone with good print-speeds.

![]()

![]()

![]()

![]()

![]()

Loctite E-3840 is low viscosity, one-component light-cure acrylic resin used for prototyping via digital light processing (DLP) or Continuous Digital Light Manufacturing (cDLM). It cures with short exposure times which results in fast print speeds and provides very high print resolution which is ideal for parts that require fine features.

![]()

![]()

![]()

![]()

![]()

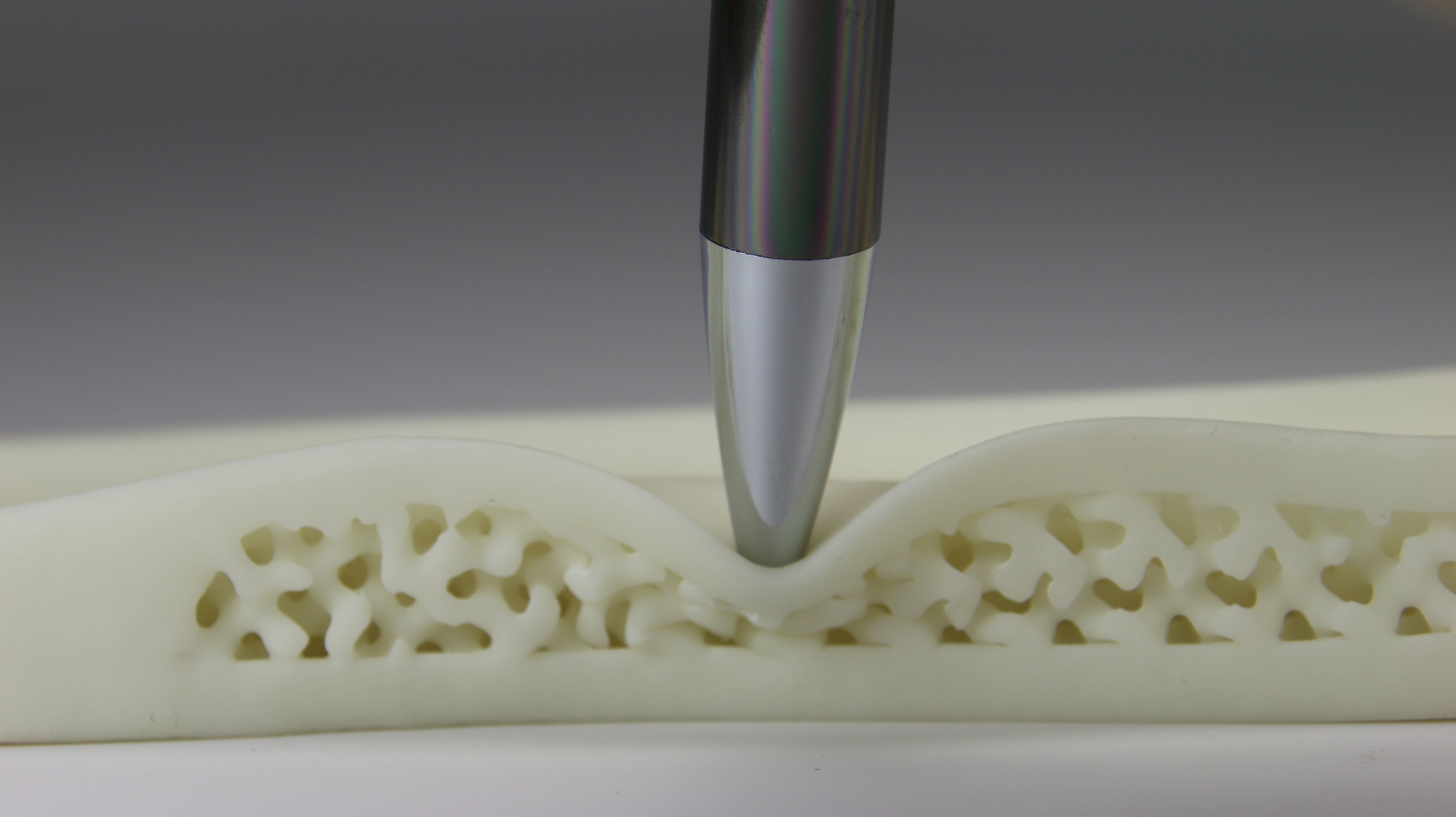

EnvisionTEC's E-RE90 is an elastomeric material with a tough, rubber-like performance, allowing for the 3D printing of parts previously made from technical foams, rubbers, or polyurethanes.

![]()

![]()

![]()

![]()

![]()

E-Aquasol is a water-soluble 3D printing resin, allowsing industrial manufacturers to shell-cast thin-walled parts with high feature resolution.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Loctite E-3955 FST HH is a high performance, high modulus product which boasts excellent flexural and tensile physical properties with outstanding flame retardance.

![]()

![]()

![]()

![]()

A semi-translucent silicone, E-UA90 is a good for general purpose elastomer parts such as robotic grippers.

![]()

![]()

![]()

![]()

![]()

![]()

Loctite E-IND402 is an elastomeric UV photocurable resin that exhibits high resilience while maintaining excellent tensile strength. It is a single component system with excellent green strength and does not require thermal post processing.

![]()

![]()

![]()

![]()

Loctite E-IND406 HDT100 High Elongation is a high-strength engineering plastic with good impact resistance, high temperature resistance, and record elongation at break.

![]()

![]()

![]()

EnvisionTEC's Rubber Elastomer E-RE70 is an elastomeric material with a tough rubber-like performance.

![]()

![]()

![]()

![]()

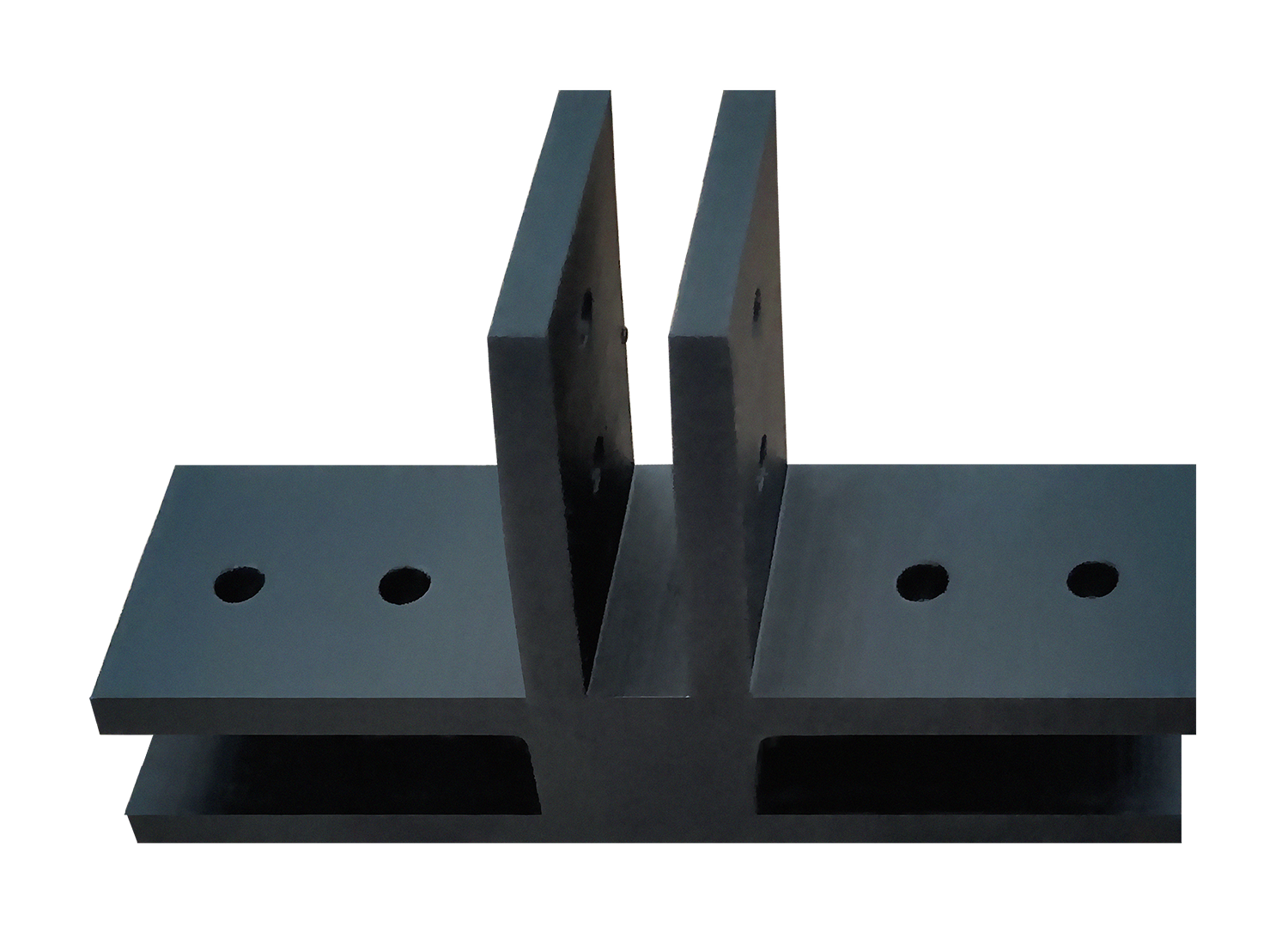

Polypropylene-based material with high impact and compression strength with greater than 100% elongation at break. Ideal for fixtures and tooling.

![]()

![]()

![]()

![]()

Loctite E-3843 is a black resin that may be used for prototyping or functional parts production. It offers good Impact resistance and thermal stability making it suitable for many demanding Engineering applications.

![]()

![]()

![]()

![]()

![]()

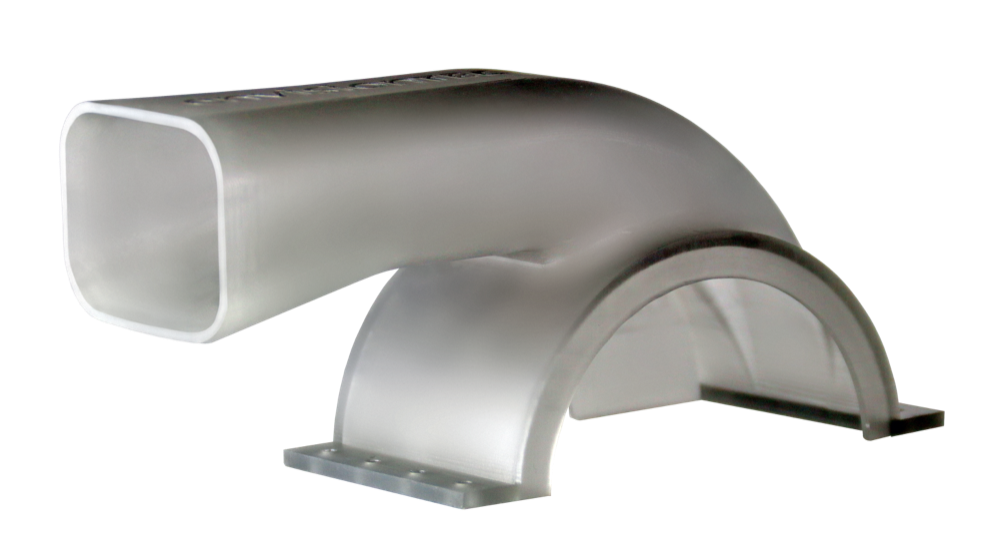

This advanced, engineering-grade material delivers large castable patterns and functional prototypes with best-in-class accuracy and surface finish. FormCast is formulated for use on EnvisionTEC's 3SP family of printers.

![]()

![]()

![]()

![]()

A semi-translucent silicone, E-UA40 has good tear strength and excellent energy rebound. It is also good for general purpose elastomer parts such as robotic grippers.

![]()

![]()

![]()

![]()

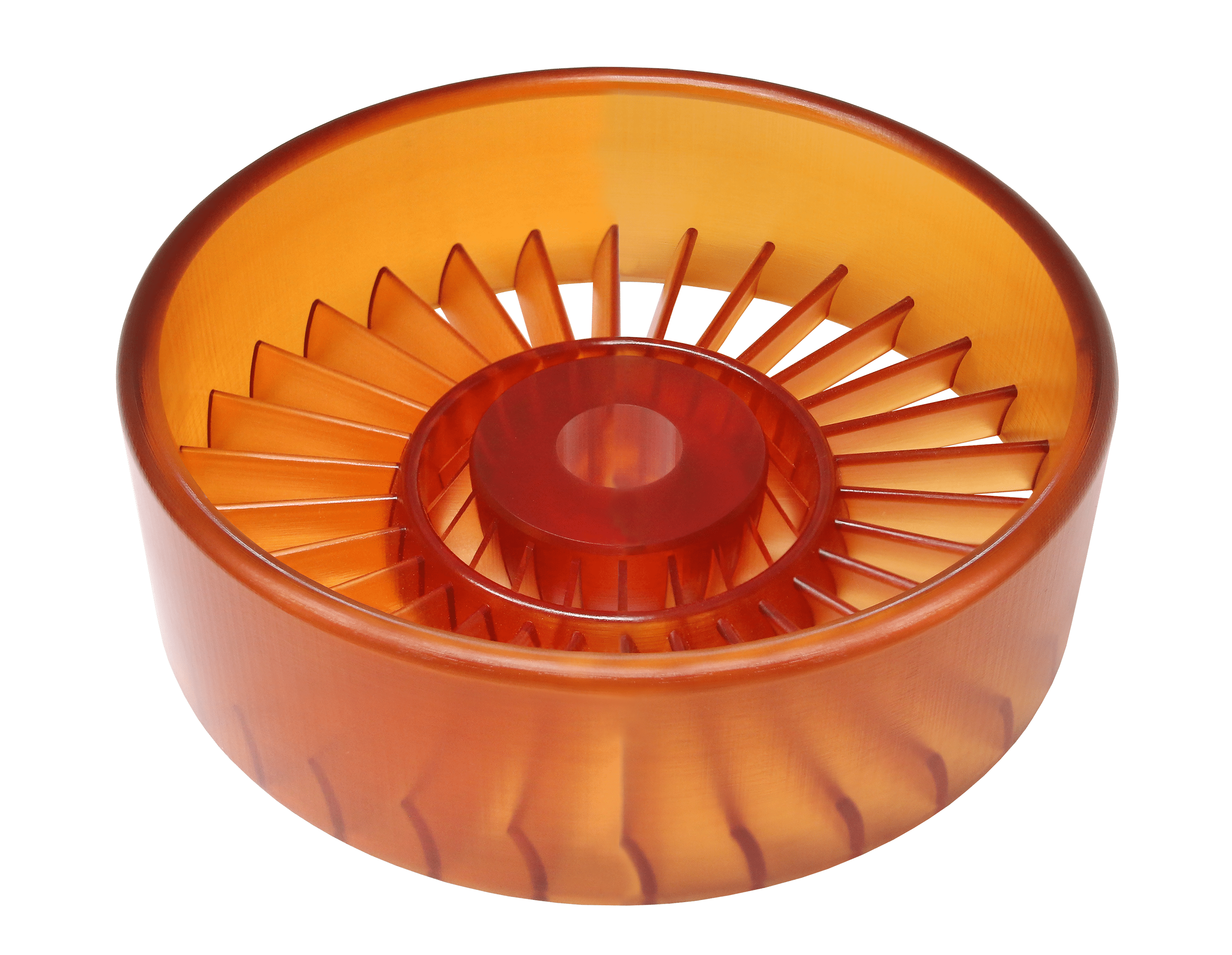

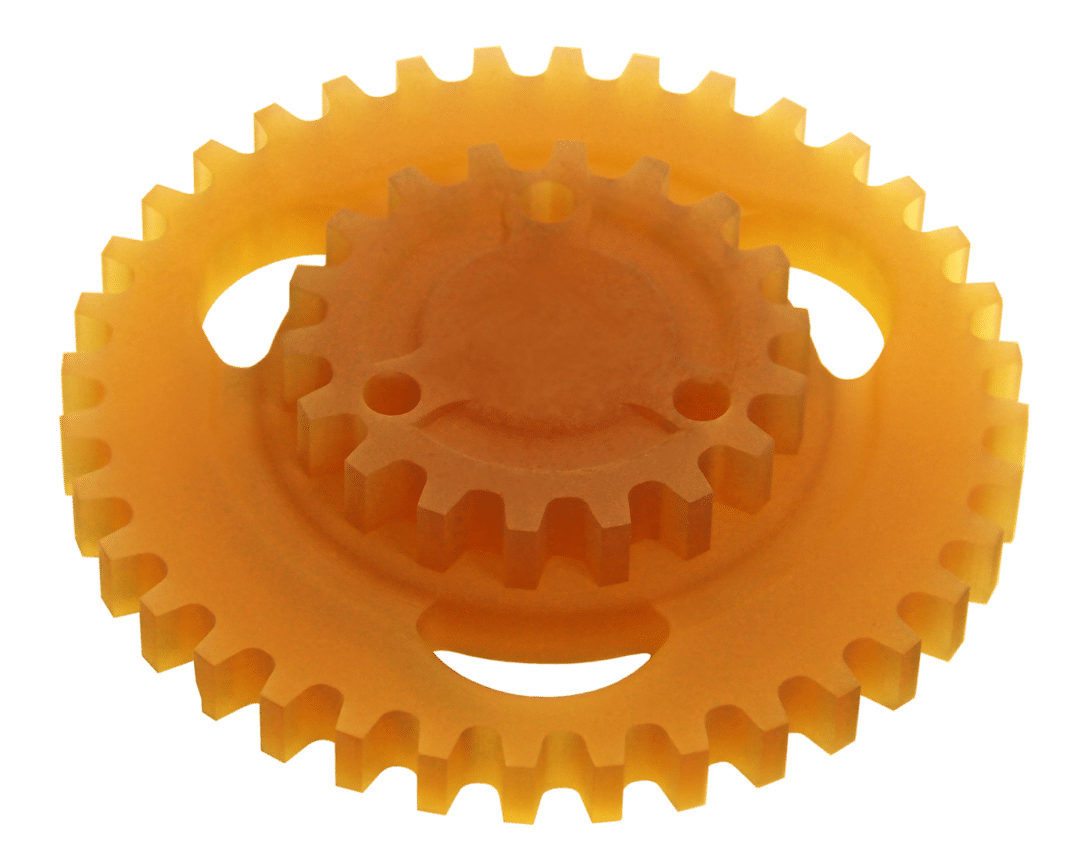

E-RigidForm is a polyurethane-like resin that 3D prints strong, hard and stiff parts that can be used for prototypes and end use. Available in translucent amber, gray and black, E-RigidForm has high tensile strength (68-73 MPa) that compares with acrylic, nylon 6 and polycarbonate. It also delivers good heat deflection and water resistance. With a hardness value of Shore D 87, the same value as a cast urethane plastic, E-RigidForm is a versatile and tough material that is ideal for a wide range of industrial and consumer applications.

![]()

![]()

![]()

![]()

![]()

This advanced engineering-grade material is a polyurethane-like material that produces a final material with soft Shore A values of 40 or 80 depending on your needs. E-Shore A is a material developed for end-use applications such as footwear, sporting goods, and other uses requiring durability, comfort and flexibility.

![]()

![]()

![]()

![]()

E-Rigid PU is a polyurethane-like resin that 3D prints end-use and prototype parts that compete with injection molded plastics. Available in black, natural and white, E-Rigid PU is hard and stiff but also maintains good strength, marked by flexibility and impact resistance. With a Shore D hardness values similar to the value as a cast urethane plastic, E-Rigid PU is a versatile and tough material. It is also an excellent solution for 3D printing dental diagnostic waxups.

![]()

![]()

![]()

![]()

![]()

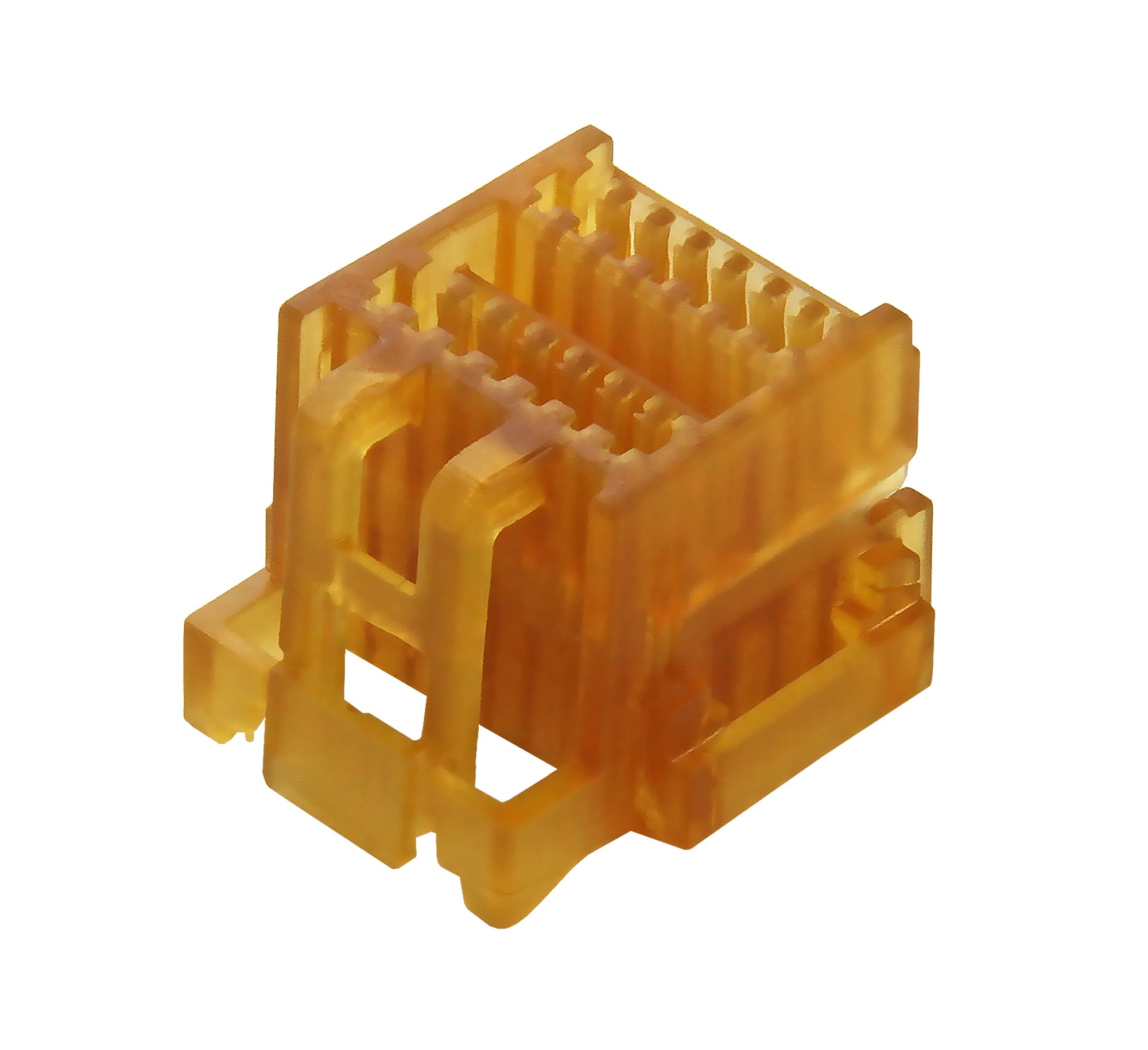

EnvisionTEC’s E-Poxy is a partially biosourced, tough, dual-cure material that delivers strong, thin-walled final products. E-Poxy offers a good relationship between flexibility, hardness and heat resistance that is also ideal for connectors, among other objects.

![]()

![]()

![]()

![]()

![]()

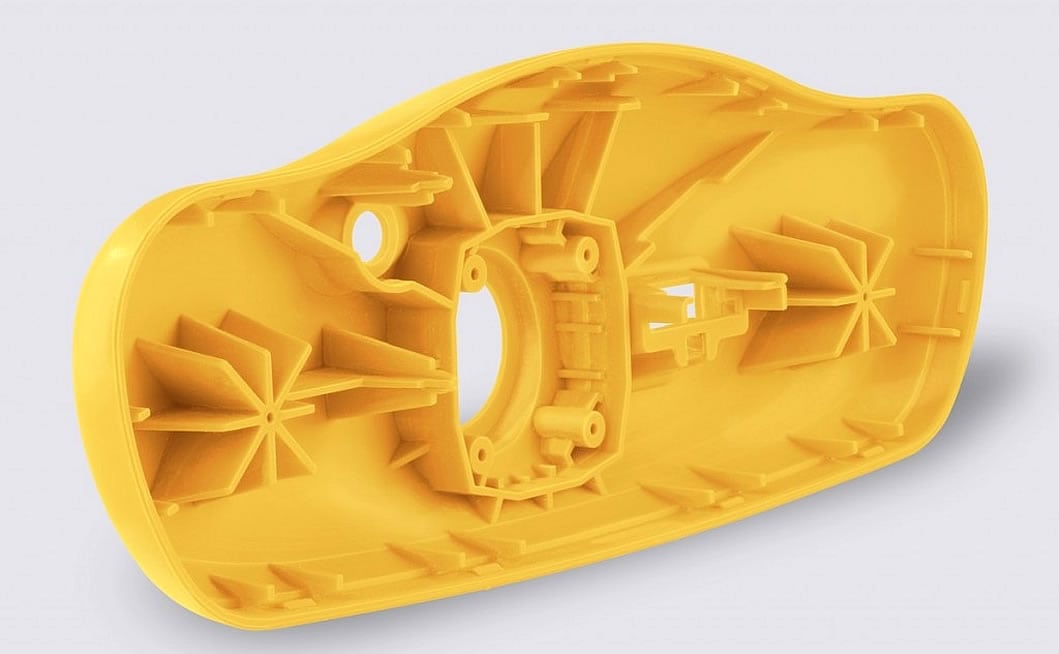

EnvisionTEC’s E-CE is a stiff, heat-resistant, high-performance dual-cure material that also offers chemical resistance. It is perfect for industrial products that require thermal stability such as electronics encasements and under-the-hood parts.

![]()

![]()

![]()

![]()

The latest breakthrough in extremely durable photopolymers for use in producing very accurate parts with high feature detail on EnvisionTEC’s 3D printers. With added stability and surface quality, this material produces parts with high impact resistance similar to thermoplastics.

![]()

![]()

![]()

![]()

![]()