Castable • Prototyping • Manufacturing

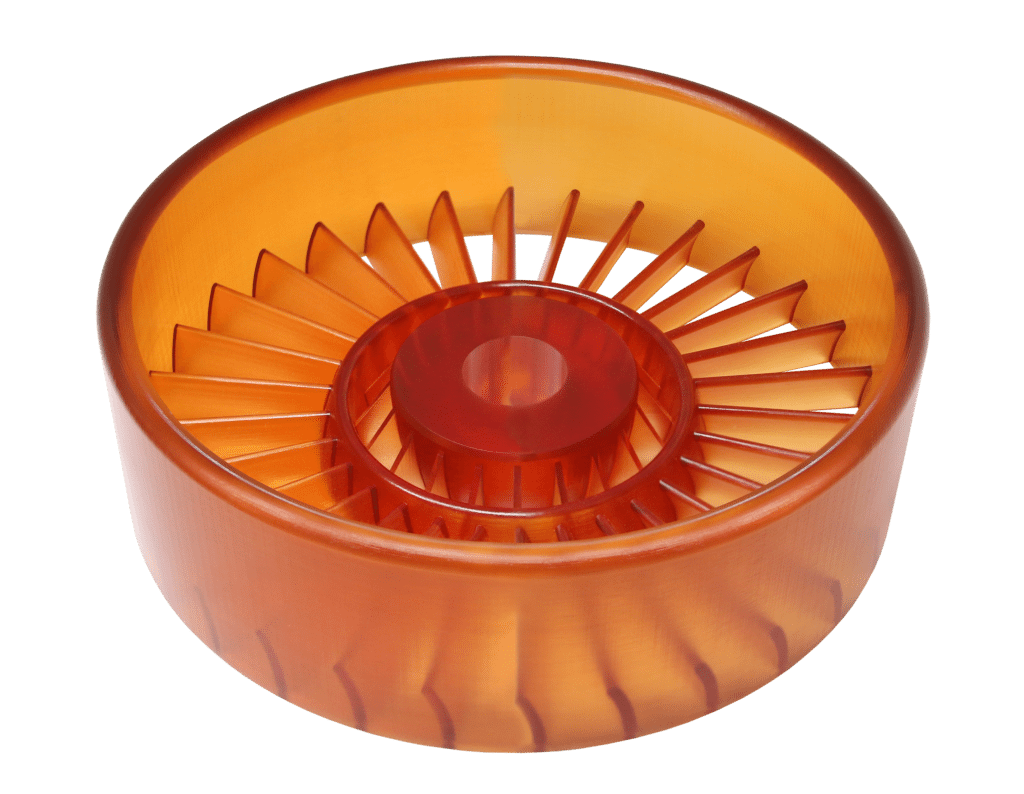

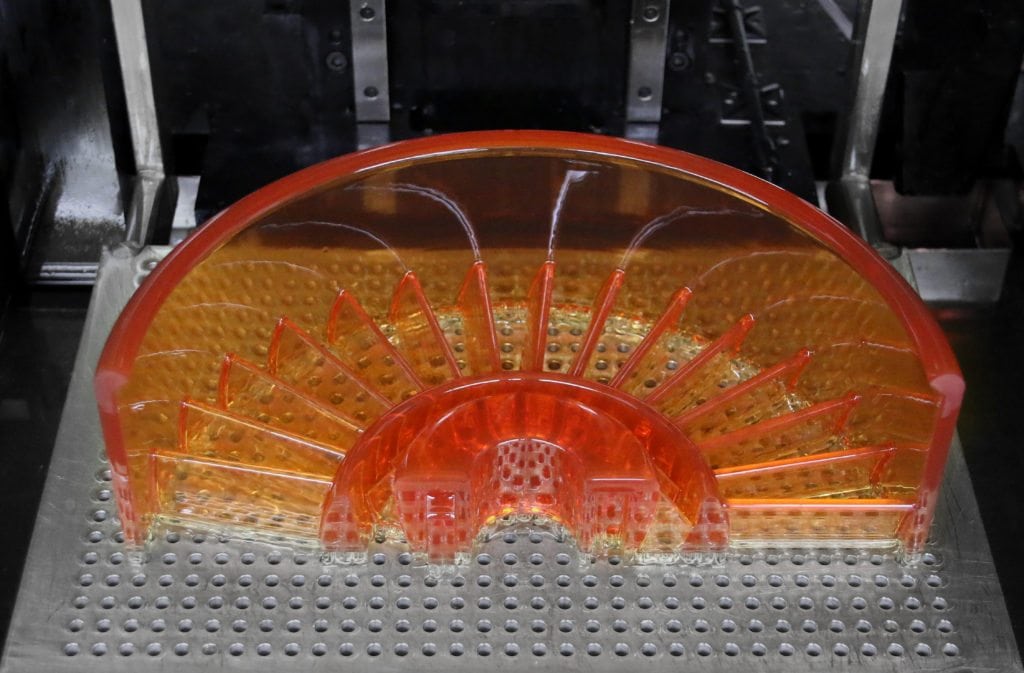

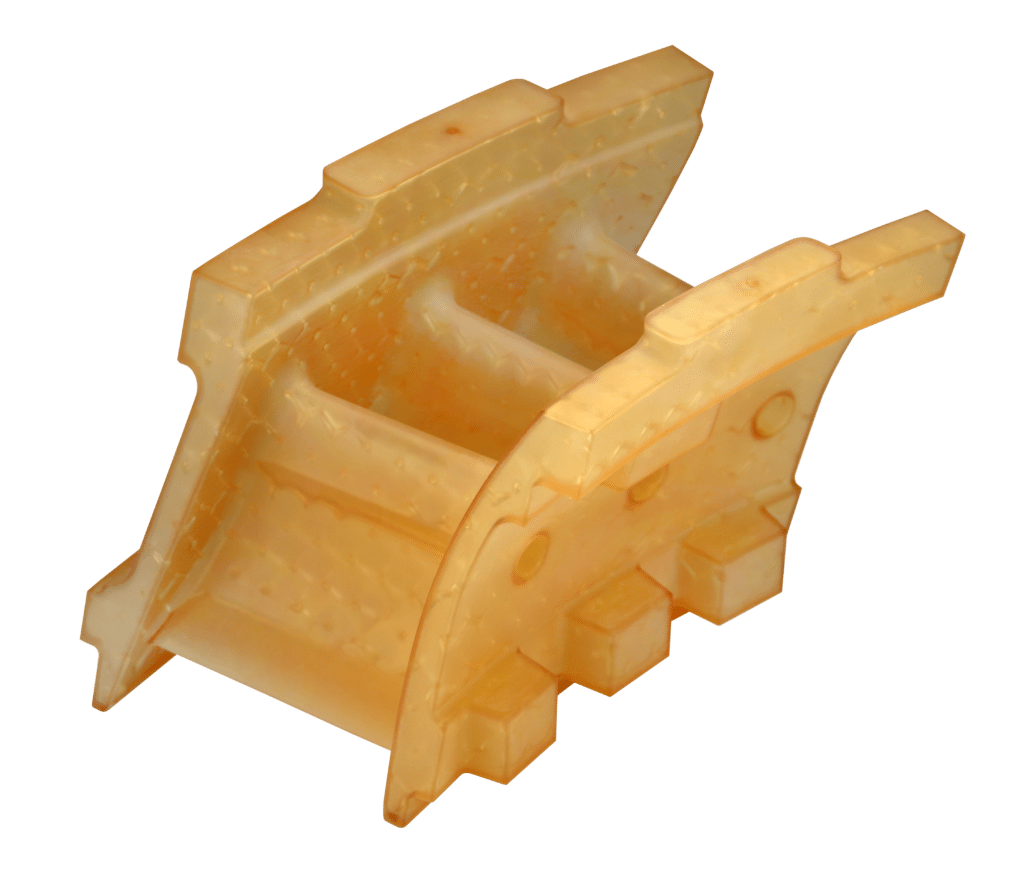

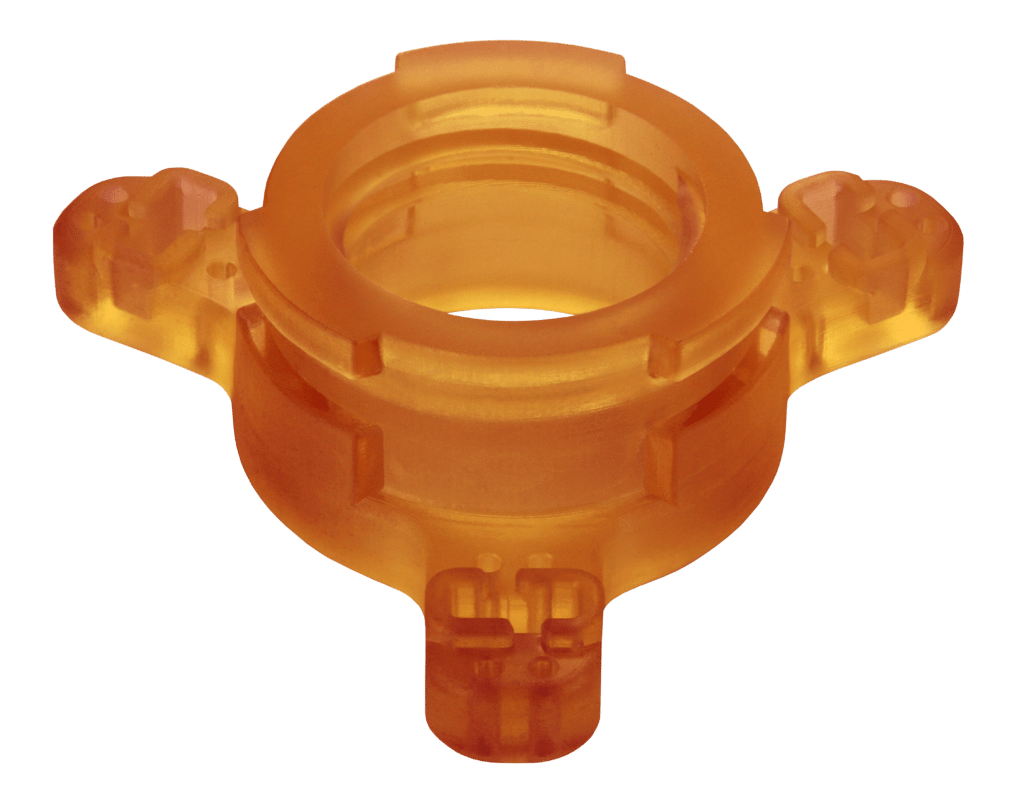

Currently in beta testing with key customers, FormCast Powered by Somos is a dual use material that can be printed on EnvisionTEC’s large-frame 3SP machines, delivering a best-in-class accuracy and surface finish for exceptional large castings.

An advanced, engineering-grade material, FormCast produces highly accurate functional prototype materials with ABS-like properties. Parts printed in FormCast can also be used for large, smooth and accurate investment casting patterns.

Because FormCast is an antimony-free formulation, it delivers a very clean burnout with low residual ash. This results in less time preparing molds and allows for the production of titanium and super alloy metal parts.

FormCast was jointly developed by EnvisionTEC and Somos.

Physical Properties

Tensile Strength

Coming Soon

Elongation at Break

4-5%

Tensile Modulus

3000 MPa

Hardness Shore D

Coming Soon

Heat Deflection Temperature

60 – 100+°C depending on UV post curing and thermal post curing procedures

Viscosity at 30°C

360 cP

Flexural Strength

Coming Soon

Flexural Modulus

Coming Soon

Izod Impact Notched

0.25 – 0.3 J/cm

Color

Transparent Yellow