Rocky Tuan, PhD, is a professor and executive vice chairman of the department of orthopedic surgery as well as the director of the Center for Cellular and Molecular Engineering at the University of Pittsburgh School of Medicine developing 3D printed cartilage with the EnvisionTEC Perfactory®. This research is the first success of living human cartilage tissue composed atop a chip using 3D printing.

The process to create cartilage fuses stem cells, activating biological components, and a tissue scaffolding. Tuan’s team uses DLP® technology to fabricate an extracellular matrix inside a solution — cells are then introduced into the solution where they may proliferate. The light technology of the Perfactory® is best for an application building with living cells– some 3D printing processes which use filaments or deposition would harm human cells while photopolymers preserve cell vitality. The amalgamation not only can sustain the shape in which it is designed — that is, in the shape of a potential patient’s defibrillated or damaged cartilage — the research team has found it can also sustain human cells.

The process to create cartilage fuses stem cells, activating biological components, and a tissue scaffolding. Tuan’s team uses DLP® technology to fabricate an extracellular matrix inside a solution — cells are then introduced into the solution where they may proliferate. The light technology of the Perfactory® is best for an application building with living cells– some 3D printing processes which use filaments or deposition would harm human cells while photopolymers preserve cell vitality. The amalgamation not only can sustain the shape in which it is designed — that is, in the shape of a potential patient’s defibrillated or damaged cartilage — the research team has found it can also sustain human cells.

Though the research isn’t ready to take the place of non-organic replacement joints, as Tuan has said, “It’s very promising and looking good.” At the least the research developed by the team can help scientists better understand what causes osteoarthritis and how to combat degenerative bone diseases with drug therapy.

The researchers use the chip to study effects on human joints in order to be able to comprehensively fight osteoarthritis and bone degeneration. This research may also eventually aid United States soldiers with traumatic injuries incurred in Iraq and Afghanistan. Pitt’s Center for Cellular and Molecular Engineering works in a partnership with Wake Forest University, the University of Pittsburgh Medical Center (UPMC) and the U.S. Department of Defense’s Armed Forces Institute of Regenerative Medicine (est. 2008), a cooperative which seeks to develop treatment for soldiers wounded in battle abroad.

Professors at the Tshwane University of Technology states that the three necessary components of tissue engineering are “signals for morphogenesis, stem cells that respond to morphogens and scaffolds that are biomimetic of the extracellular matrix to create human spare parts.” In order for a bioprinter to be a useful tool in human tissue engineering work, it needs to be able to commission a biomimetic extracellular structure.

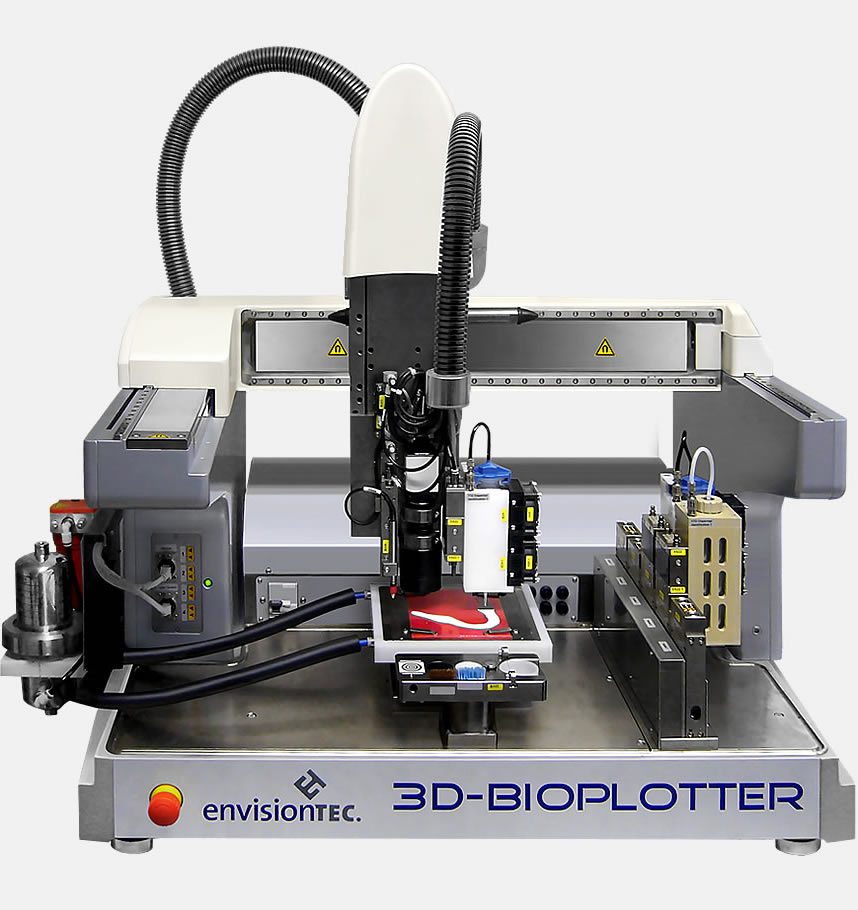

The 3D-Bioplotter® plots scaffolding out of organic materials for the purpose of supporting intracellular processes and function within a supportive structure. The bioprinter system uses a scaffolding technique to achieve a “biomimetic” reaction. Rather than placing spheroids of cells, the Bioplotter prints a much smaller amount of cells into the 3D scaffold shape.

“After some time, the cells will have multiplied and digested the scaffold material, created its own ECM [extracellular matrix], which holds the 3D shape in place and thus creates a scaffold-free part,” says EnvisionTEC’s bioprinting expert Dr. Carlos Carvalho. “For [the EnvisionTEC Bioplotter] we use an otherwise unheard policy in 3D printing: our customers have complete freedom in the choice of materials they wish to use.”

3D-Bioplotter

Dr. Montaug believes that tissue engineering is an imperative research sector to combat organ shortages and organ rejection. Instead of waiting for an organ replacement from a closely-matched donor, patients in need could feasibly grow a replacement organ from their own cells — more quickly and with greater viability.

The process of implanting living cells within a biomimetic organic scaffolding has been employed in several research laboratories aimed at developing tissue replacements for patients. Dr. Ramille Shah, head of SHAH Lab at Northwestern University, uses a 3D-Bioplotter heavily in her research developing viable bone tissue for transplants as well as a new class of 3D printed materials which she dubs “bio-inks”.

Other clients have found success using Perfactory® series 3D printers. Dr. David Dean at Ohio State University uses a Perfactory for constructing craniofacial tissues. Dr. Rocky Tuan at the University of Pittsburgh works with his Perfactory building living cells with the light-based technology. Tuan has made recent advancements in the field of tissue engineering with living joint cartilage as well as skin grafts for burn victims.

Interested in biofabrication from EnvisionTEC? Contact us today