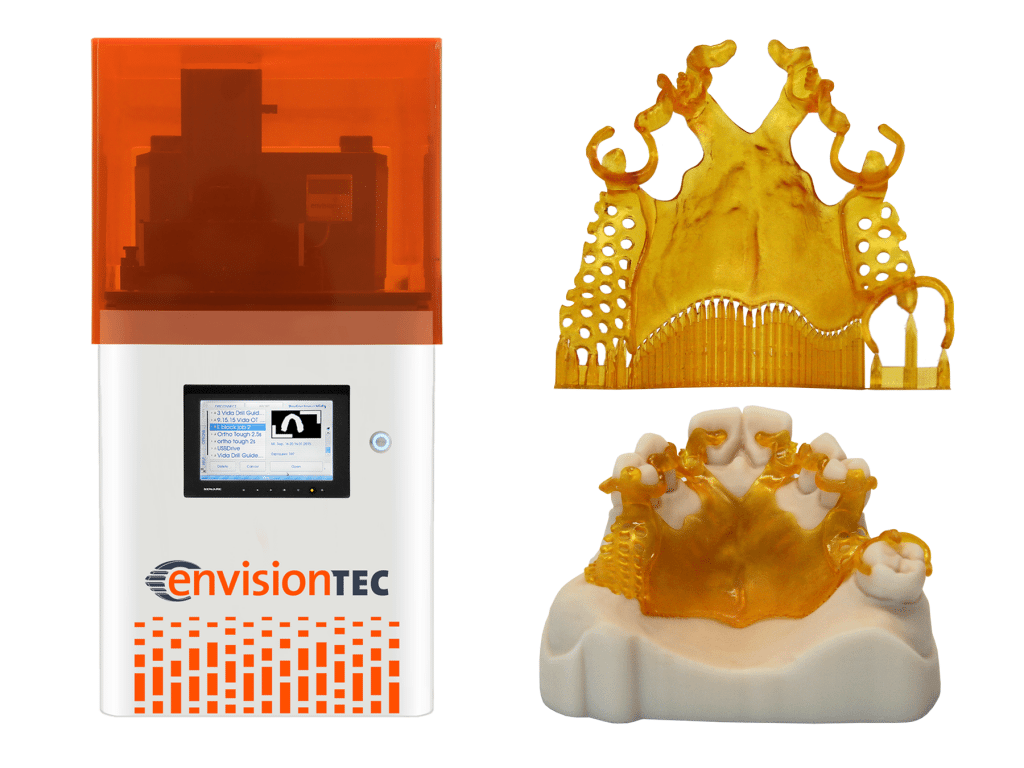

The Vida cDLM is a high-speed continuous 3D printer for the jewelry, dental and general manufacturing markets. This printer is offered using EnvisionTEC’s patented Continuous Digital Light Manufacturing (cDLM) technology and offers high resolution combined with blazing speeds. In addition, the technology also reduces the need for support structures during 3D builds, meaning less finishing is necessary. The larger build envelope allows for larger parts or higher productivity without sacrificing speed.

This groundbreaking technology allows for disruptive printing across a range of industries including:

- Dental

- Jewelry

- Manufacturing

As with all EnvisionTEC technologies, the Vida cDLM delivers outstanding surface quality with no signs of stairstepping. With the largest build envelope available in cDLM technology, the Vida cDLM allows for high quality results from a manufacturer with more than 15 years of experience in 3D printing technologies.

Machine Properties

Build Envelope

145 x 81.5 x 100 mm (5.7 x 3.2 x 3.94 in.)

XY Resolution*

76 µm (0.003 in.)

Dynamic Resolution in Z (material dependent)

25 to 150 µm (0.001 to 0.06 in.)

Light Source

Industrial UV LED

Data Handling

STL

Warranty

1 year back to factory including parts and labor

System Properties

- Compatible with all design software capable of outputting an STL file

- Changeover between materials is quick and easy with no waste.

- Plug and play with an easy to use software interface.

- Very few moving parts guarantees a strong and reliable production system.

- Footprint (L x W x H): 39.5 x 35.0 x 78.7 cm (15.55 x 13.75 x 31 in.)

- Weight: 34 kg (75 lbs)

Materials Available

A biocompatible crystal clear material for accurate bite and night guards

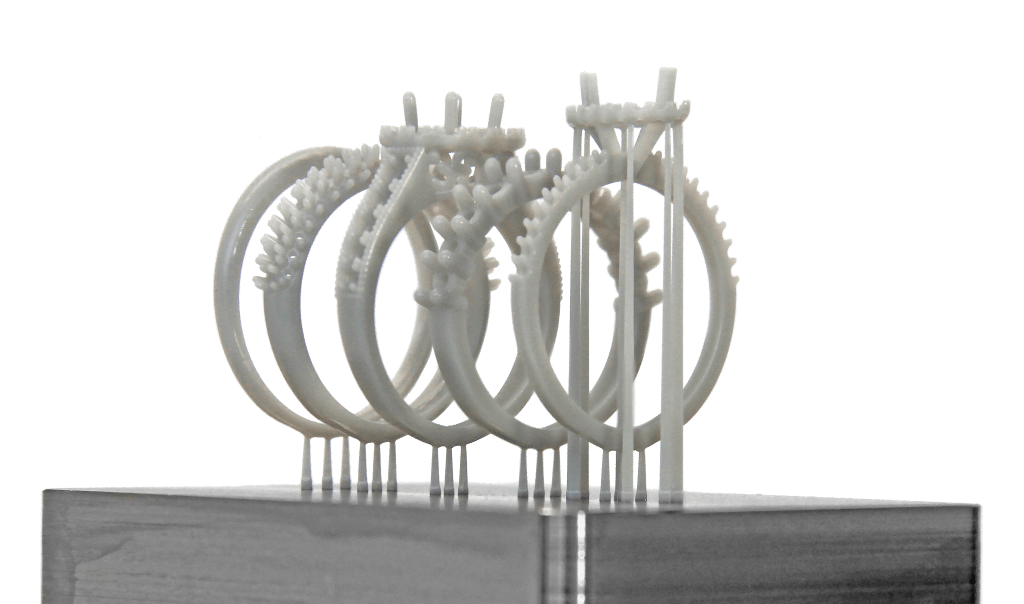

A low-wax 3D printing material ideal for professional retail and jewelry customers who require flexibility between large and small pieces

A popular casting material, PIC 100 is ideal for printing jewelry, dental and other parts requiring exceptional detail and surface finish

Super-fast printing material for quick design verification models

Prototype and end-use model printing

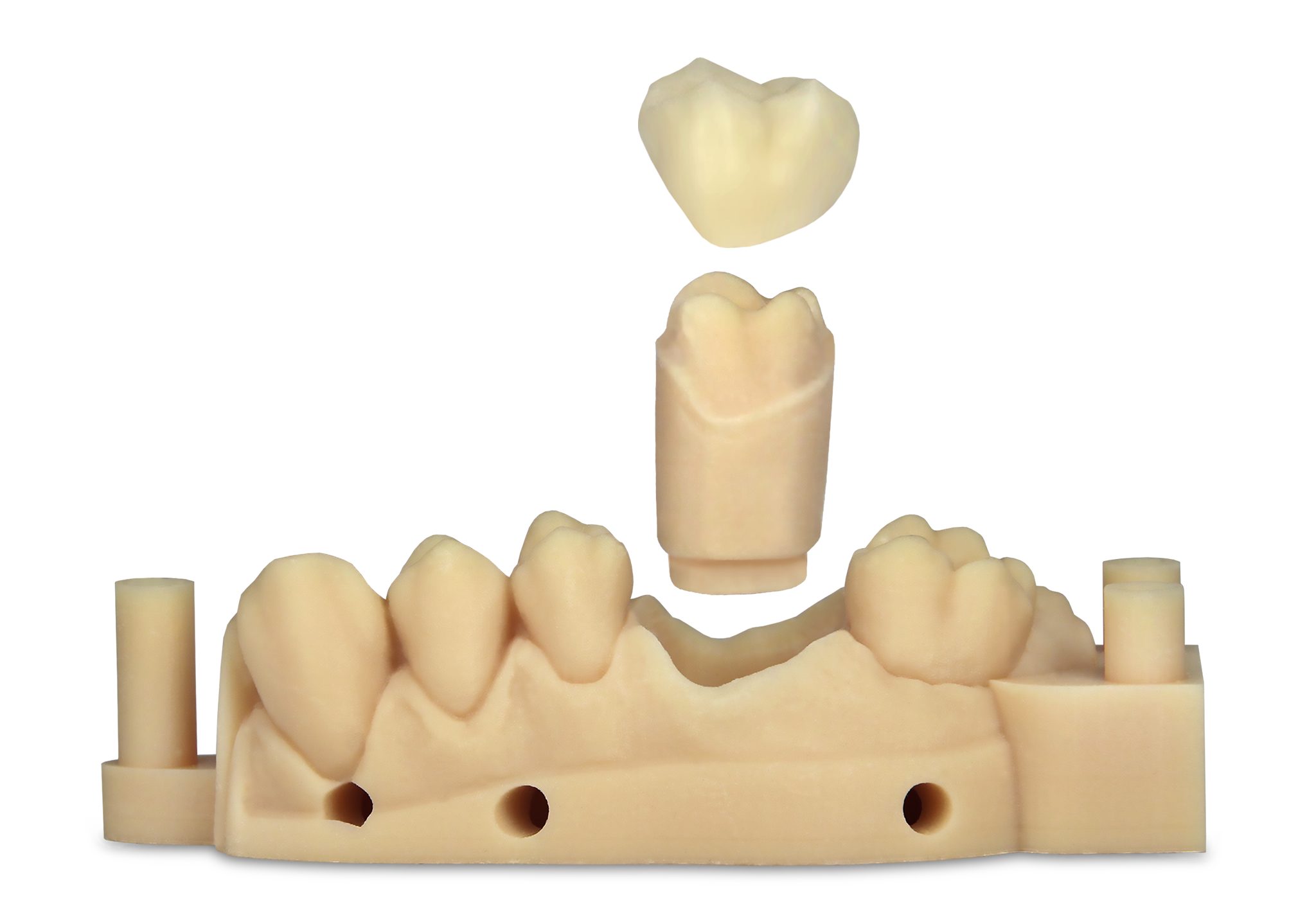

Dental crown and bridge material

A breakthrough material for the high-speed printing of a castable photopolymer with the highest wax content available in 3D printing

A biocompatible material for direct 3D printing of pink denture bases

robust, accurate, and functional parts

robust, accurate, and functional parts

robust, accurate, and functional parts

A biocompatible material for precision surgical drill guides used in surgery

3D Printing material for injection molding

Applications

High-Speed Continuous 3D Printing for a Variety of Industries

DENTAL

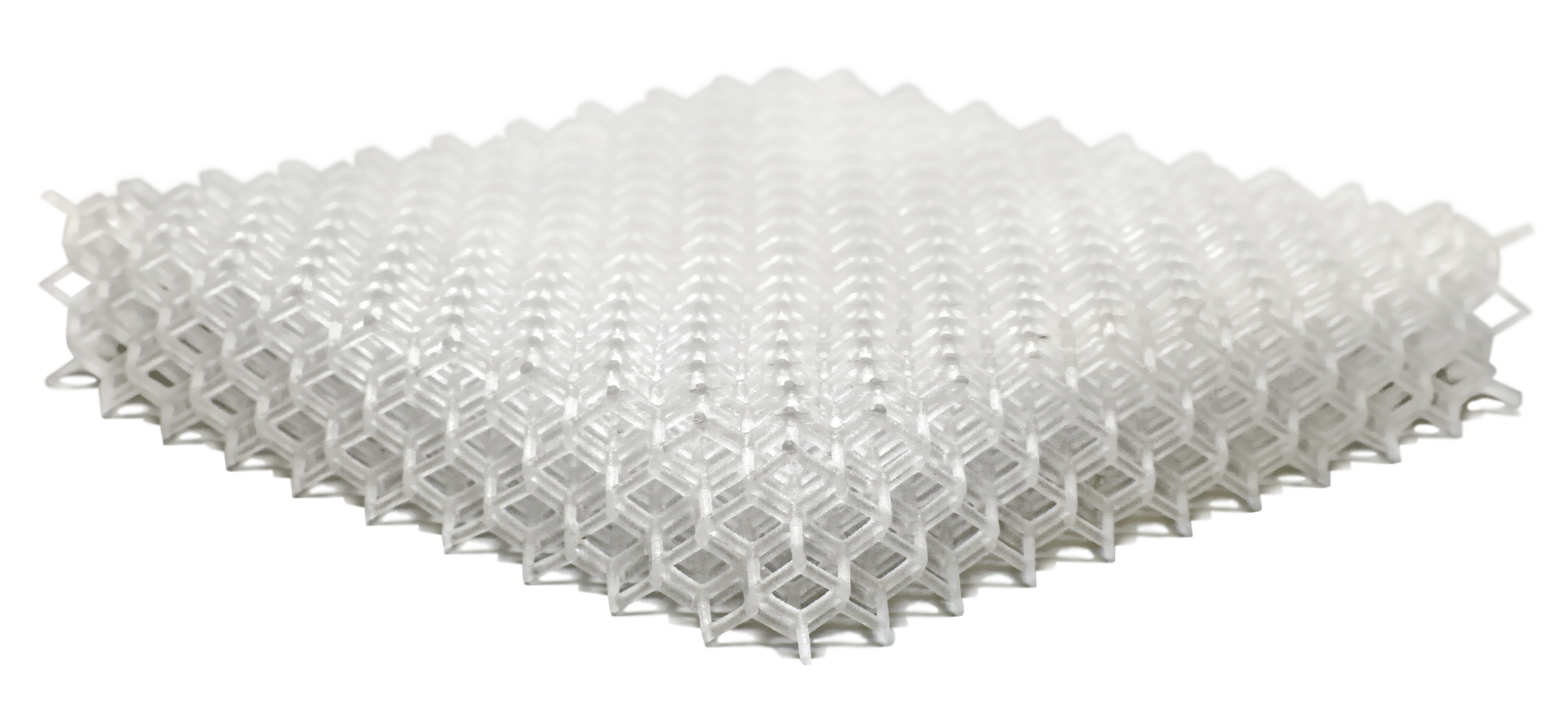

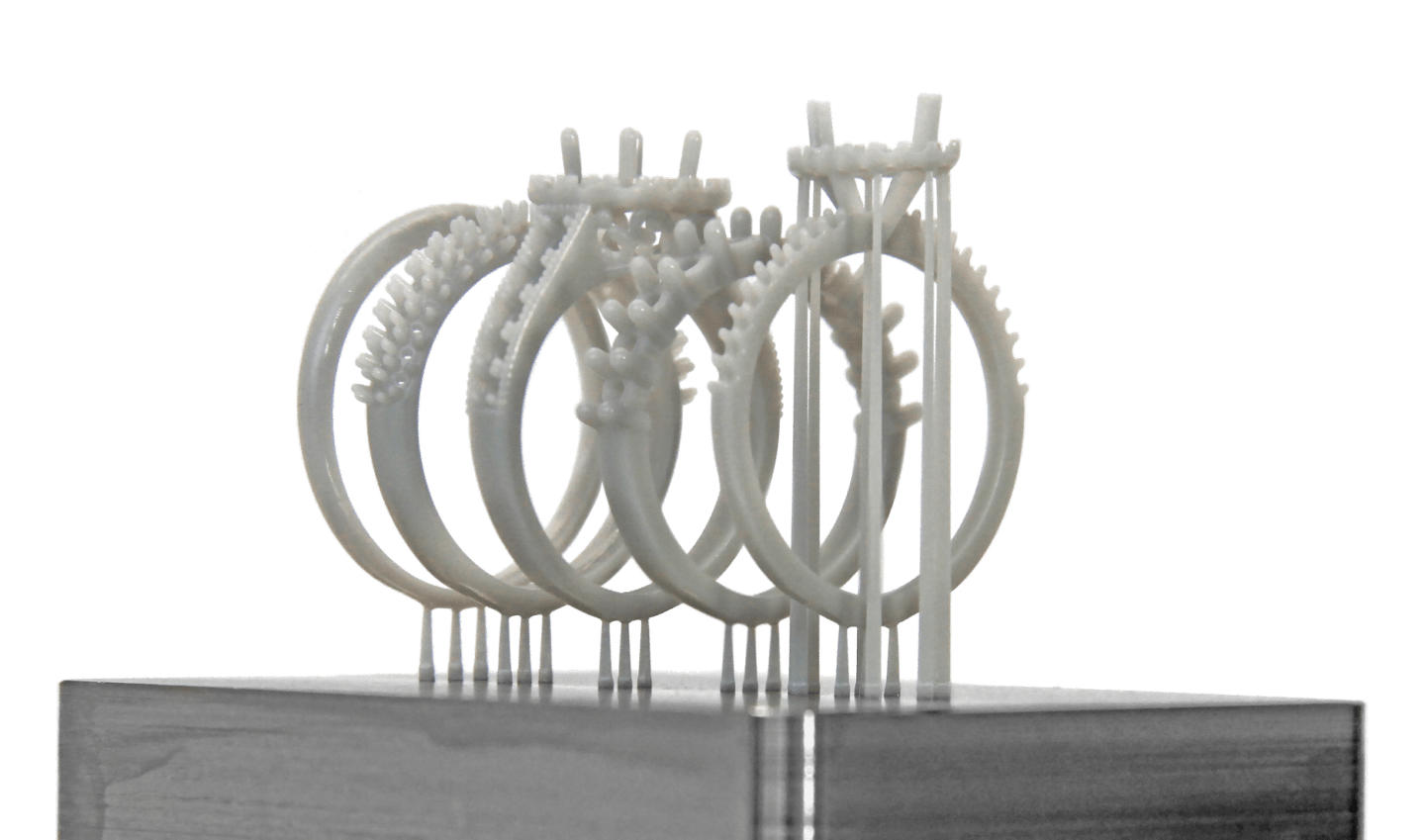

JEWELRY

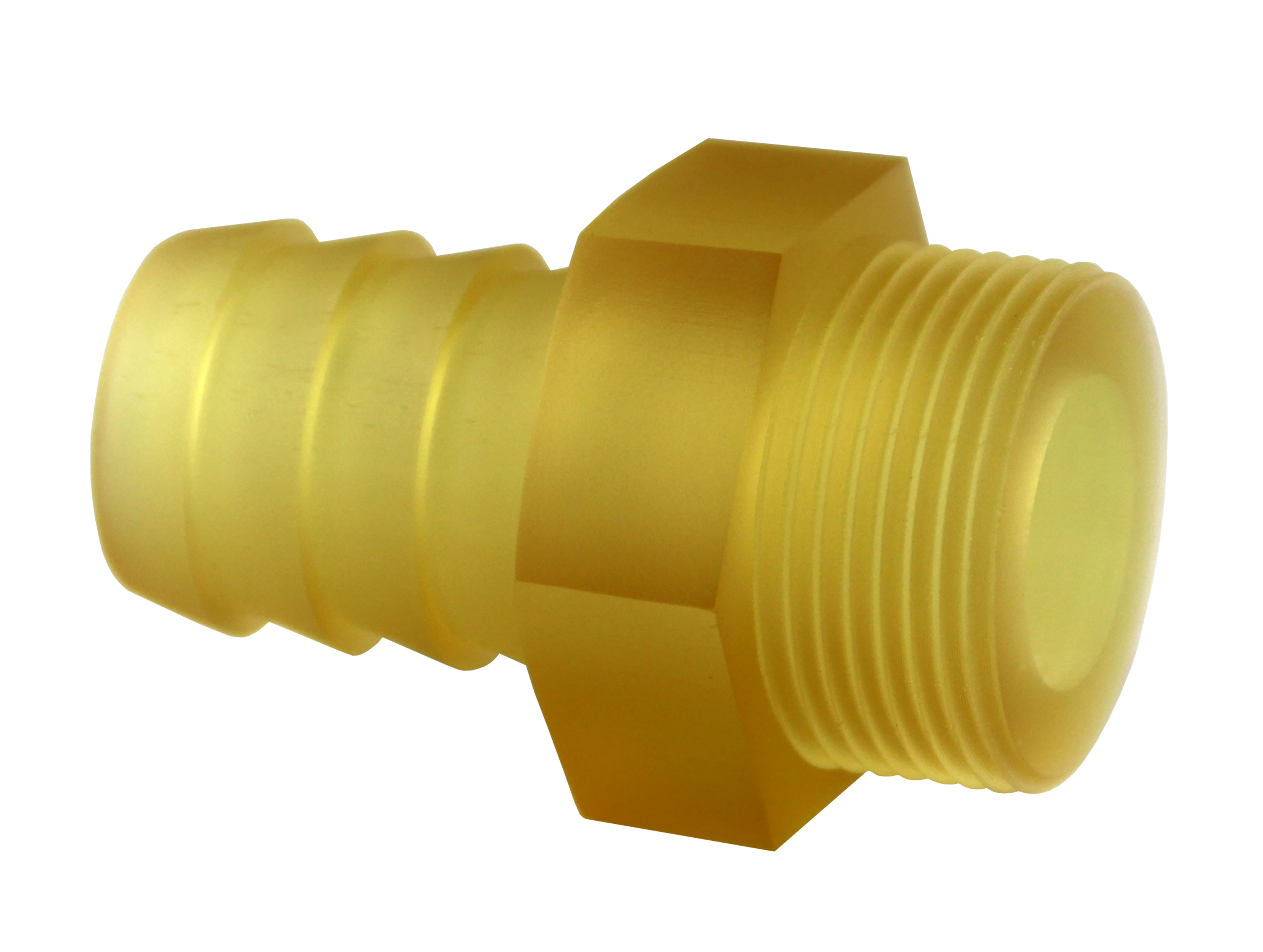

MANUFACTURING

Related Printers:

Vida HD cDLM

The Vida HD cDLM is a high-speed continuous 3D printer for the jewelry, dental and general manufacturing markets. This printer is the second offering EnvisionTEC’s patented Continuous Digital Light Manufacturing technology and offers high resolution combined with blazing speeds. In addition, the technology also reduces the need for support structures during 3D builds, meaning less finishing is necessary.

Build Envelope

90 x 50 x 100 mm (3.54 x 1.97 x 3.94 in.)

XY Resolution*

50 µm (0.002 in.)

Primary Markets

Materials Available for the Vida cDLM Printer

E-Guard is a biocompatible transparent material for the production of accurate orthodontic bite splints and night guards. The results produced by combining E-Guard with EnvisionTEC technology are superior to traditional methods of manufacturing bite guards and night guards. It is a clear material, allowing for maximum visibility.

![]()

EnvisionTEC’s E-Guide is a biocompatible certified Class I material, developed for the production of high precision surgical drill guides for use in implant surgery. The results produced by combining E-Guide with EnvisionTEC technology are superior to traditional methods of manufacturing implant placement guides.

E-Model Light DLP printing material for DLP and cDLM 3D printers is the perfect choice for a wide variety of high-accuracy dental modeling needs.

EnvisionTEC’s E-Mould provides a new solution for injection molding with a validated process chain.

![]()

![]()

![]()

![]()

A semi-translucent silicone, E-UA40 has good tear strength and excellent energy rebound. It is also good for general purpose elastomer parts such as robotic grippers.

![]()

![]()

![]()

![]()

A semi-translucent silicone, E-UA90 is a good for general purpose elastomer parts such as robotic grippers.

![]()

![]()

![]()

![]()

![]()

![]()

A breakthrough material for the high-speed printing of a castable photopolymer with the highest wax content available in 3D printing.

![]()

A low-wax 3D printing material, EPIC delivers results similar to EnvisionTEC’s wax-free PIC material, but with 8% liquid wax for lower thermal expansion during burnout. Ideal for customers who require flexibility between large and small pieces and have expert-level quality control in casting.

![]()

A popular production casting material, PIC 100 is ideal for printing jewelry, dental and other parts requiring exceptional detail and surface finish. In jewelry, PIC is recommended for pieces up to 5 grams finish weight, such as bridal jewelry.

![]()

![]()

![]()

![]()

![]()

EnvisionTEC’s quick building QView resin is ideal for providing fast design verification models. This exciting new material is capable of impressive print speeds for the full build envelope. This allows designers to put their custom design pieces into their customers’ hands in record time for final fit and design verification. It can also be used as a pattern when built in high resolution to make a silicone mold.

![]()

![]()

![]()

R5-385 material is an update on the original R5 material, one of EnvisionTEC's earliest materials still in use around the world, re-engineered for optimal performance in 3D printers utilizing 385nm wavelength light sources.

![]()

![]()

![]()

![]()

![]()

![]()