British Touring Car team turns to EnvisionTEC to provide the competitive edge

The Team HARD brand was created in early 2012 by BTCC driver Tony Gilham. Tony has competed in British motorsport every year since 2005 and has expanded the team over the past decade to include: a team of Volkswagen Racing cup drivers, a Volkswagen Racing scholarship, VAG trophy, Ginetta Supercup, BTCC and Britcar. In all, Team HARD manages in excess of 20 drivers, with an impressive record of wins. In 2016, the team won the prestigious British GT 4 championship and it continues to grow and improve.

Tough regulations

To ensure that the competition is fair and ensure that smaller independent teams can compete against better funded ones, the BTCC ensure that all cars are built to the same NGTC (Next Generation Touring Car) regulations. Team HARD is no different, being limited to the standard engine specification, drive train, suspension and brakes. This means that to gain any sort of advantage, teams need to ensure that the engineering of the car surrounding these components is better than that of their peers.

Working within the regulations

Team HARD had a number of ideas of ways in which they could increase performance of the standard systems to give them advantage.

The team has been using costly off-the-shelf solutions to provide the air ducting. These parts were not specific to their car resulting in a less than perfect fit and less than optimal airflow to the brake components.

Ensuring the supplied brakes were fed with as much cold air as possible became a focus of their efforts. This enhanced airflow to the brakes ensures that the disks are cooled faster reducing brake fade and allowing later braking into corners. To this end, the ducting and intakes for the GT4 and BTCC cars were examined and with the support of EnvisionTEC, new re-engineered, more effective solutions were developed and printed.

Building the solution

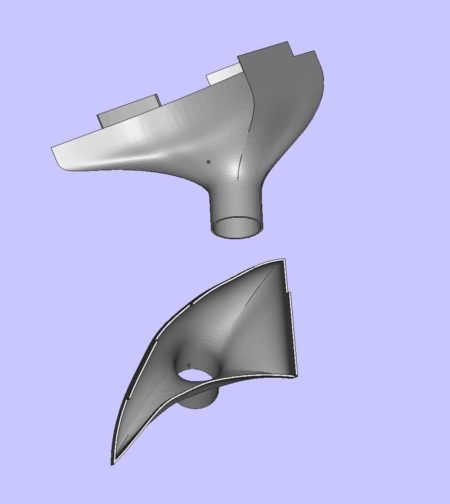

To get started EnvisionTEC scanned the existing ducts to give the engineers a base model to modify. This was then transferred to CAD to be manipulated. Simulations ensured that the parts being produced were the most efficient possible.

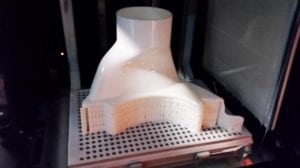

Once the designs were finalized in the computer, they were then sent to EnvisionTEC to be produced. The team at EnvisionTEC chose the Ultra 3SP printer model due to its build size and accuracy, together with ABS Tough, an extremely tough ABS-like 3D printing material with enough flex to absorb the stresses of racing.

Testing fit and finishing

The first set of models produced were then used for form and fit testing, allowing the team to check their work with the cars as designed. These also gave the engineers the opportunity to make final adjustments.

Once the adjustments were made the final parts took a matter of hours to produce. In the case of the ducts, these were additionally electroplated to ensure the smoothest surface possible and to help insulate the parts from the extreme heat generated by the brakes.

The advantages of 3D printing for Racing and Automotive

3D printing removes much of the effort and cost associated with traditional manufacturing. With 3D printing, the parts can be tested, tweaked, re-designed and printed in a matter of hours not weeks. The range of automotive focused materials is now vast, allowing engineers to choose the exact properties they need.

Motorsport teams can now choose from a large range of tough or flexible lightweight materials. Rapid prototyping and development 3D printing is revolutionizing prototyping and development. Prototyping is a traditionally long and expensive process involving the repeated re-manufacture of components for testing. Metal components for example need designing, casting, adjustment and re-casting. With 3D printing, components are often able to be tested and re-printed before a casting is even considered, this reduces design cycle time and costs.

Develop bespoke items to exact requirements

Where the manufacture of bespoke parts would have been previously prohibitively expensive, with the outsourcing of production and repeated iterations, this can now be done in house and testing undertaken before any manufacturing costs are incurred. 3D printed parts bring many advantages in that they are designed for the individual car and the specific purpose. There are little to no limitations in the geometries that can

be built.

EnvisionTEC provides a range of tough ABS materials allowing components to be bench tested, or test fitted prior to production. There are even castable materials for the rapid production of metal components.

Partners

EnvisionTEC undertook the production and finishing of the parts for the car, additional thanks go to iMakr for its advanced scanning support and to 3DDC for its support in electroplating the final ducts.

Find out more

To learn more about EnvisionTEC’s range of automotive focused printers and materials visit our dedicated pages here.