Learn How 3D Printing is Transforming Biomimicry Research, Design and Materials

McGill University’s Laboratory for Advanced Materials and Bioinspiration uses 3D printing technology to replicate nature’s own textiles and patterns to better understand tough designs that are resistant to puncture and more.

Imagine building a jigsaw puzzle out of ABS plastic that is 45 times tougher than a sheet of the same plastic. Or fabricating a new type of glass that can deform and resist impact 700 times better than regular glass. This is exactly the kind of work being done at McGill University’s Laboratory for Advanced Materials and Bioinspiration in Montreal, Canada.

As the lab name suggests, these amazing new developments take their cue from nature, which often manages to combine properties that are traditionally incompatible in engineered materials. Consider, for example, the hardness and toughness found in seashells or the combined hardness and flexibility in scaled skins.

Decoding the micro-mechanics behind the performance of these materials requires building accurate models and experimenting with variations in the lab, and McGill uses a desktop 3D printer from EnvisionTEC — a 2014 Micro Hi-Res — for its research.

“3D printing is not a one-size-fits-all solution to all current engineering and manufacturing challenges, but it can be a very powerful tool,” explained Francois Barthelat, lab leader and associate professor of McGill’s Department of Mechanical Engineering. “There are more and more people like us using 3D printers in biology and bio-mechanics to make models and working prototypes to understand the mechanics better.”

A fishy mathematical problem

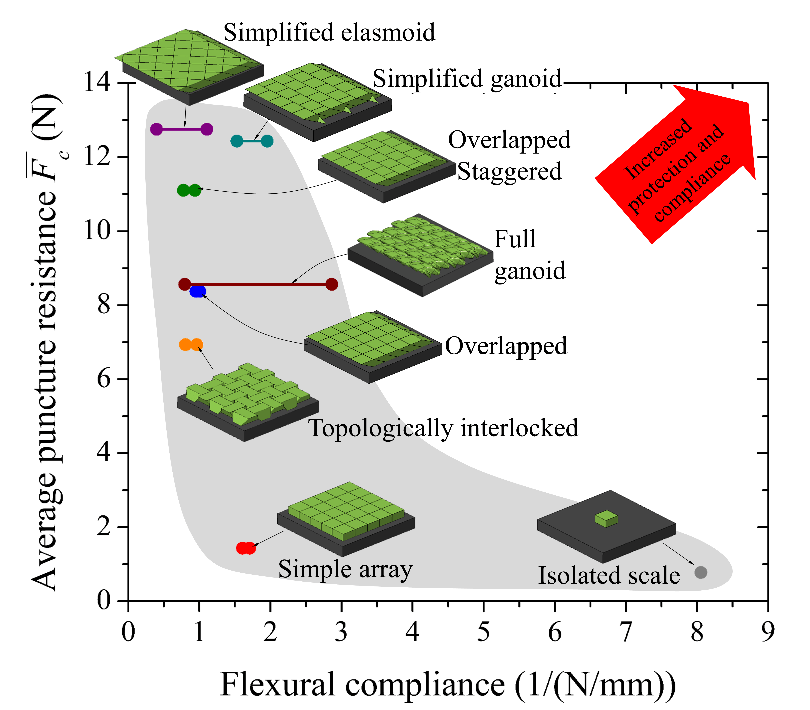

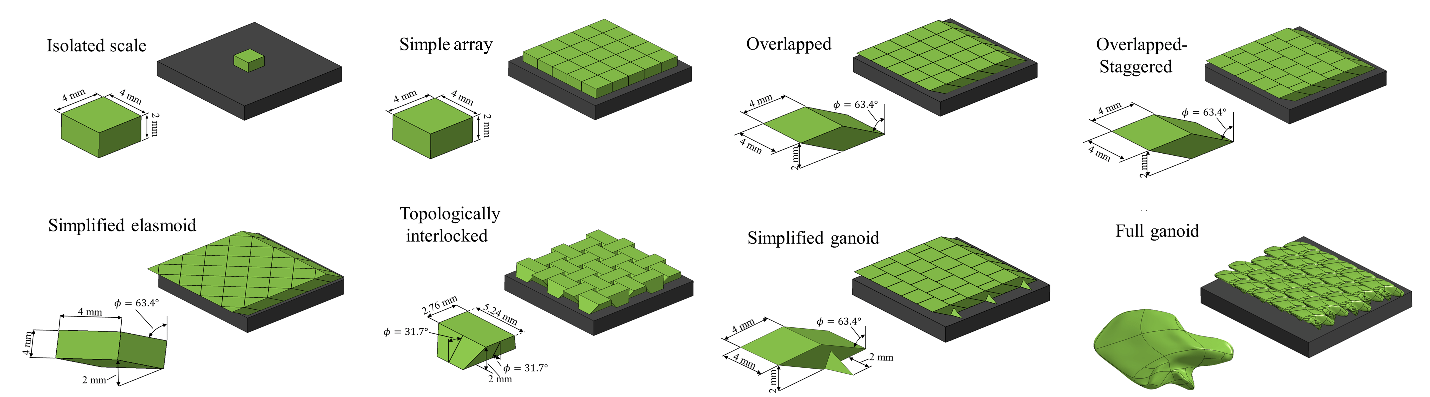

With an eye toward improving personal protective gear, the team at McGill recently studied the natural armors of fish, alligators and armadillos, to better understand their unique combination of hardness, flexibility, and light weight. The goal was to study how the size and shape of the scales interacted to provide both puncture resistance and flexibility, and how best to optimize and balance these attributes in design.

“Computer models quickly become complex and have a hard time trying to capture the physics of what’s going on in cases like this,” Barthelat explained. “It’s very straightforward to compute the stresses and deformation of a single component under a specified load. But if you have two components in contact, you need to manage what’s happening in the contact, and this … creates numerical problems and becomes very expensive to model, even for only one contact pair.

“If you try to capture what’s happening with things like fish scales, where you may have 10, 20, or 30 contact pairs to handle, it becomes a nightmare. It’s just not practical to analyze numerically with a computer.

“Interestingly for these cases it’s much faster, easier, more reliable and accurate to 3D print the scales, up to 10 or 20 objects that will interact, and do mechanical tests directly.”

The 3D printed winner was prehistoric

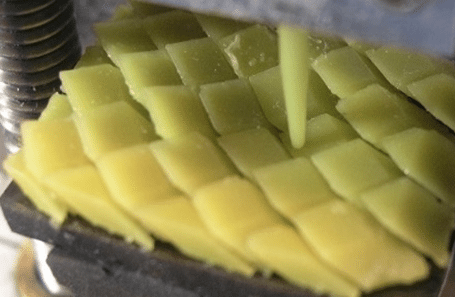

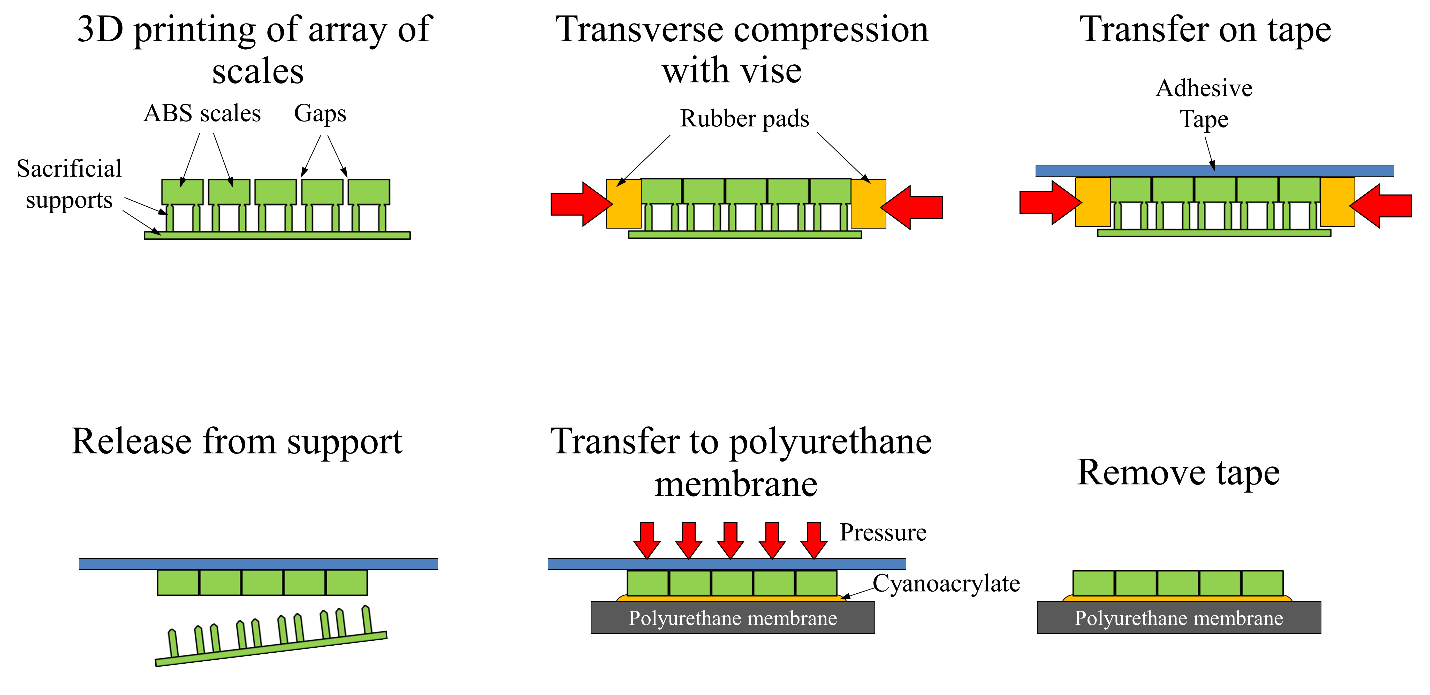

So Barthelat and his students used the EnvisionTEC 3D printer to create “scales” in ABS (acrylonitrile butadiene styrene, a relatively stiff polymer with modulus E=3 GPa, Poisson’s ratio v=0.35). They arranged the scales in 5×5 arrays, with no gaps between them, and glued them onto a softer substrate (polyurethane, modulus E~0.7 MPa, Poisson’s ratio v~0.5). Then they performed puncture tests at 30 different locations across the array using a needle 3D printed in the same ABS.

They tested eight geometries, starting with a single, isolated rectangular scale (i.e. not a 5×5 grid of smaller scales). They then tried arrays of interlocking or overlapping scales of increasing complexity. The features they added were inspired by those observed in nature, culminating with ganoid scales they copied from an ancient fish (polypterus senegalus) using microCT scanning.

As their research report, published in the March 2017 Acta Biomaterialia puts it, the team found that “the interactions between the scales can significantly increase the resistance to puncture, and these interactions can be maximized by tuning the geometry and arrangement of the scales.” The designs offering the best combinations of puncture resistance and flexibility were similar to the geometry and arrangement of natural teleost and ganoid scales, suggesting that “natural evolution has shaped these systems to maximize flexible protection.”

Barthelat reiterated that it was 3D printing that enabled the team to “optimize the size and shape and arrangement of the scales so that we know exactly what to do for real world applications, like gloves. With 3D printing we can explore many more geometries. And once we have the right geometry we can put resources and time into applying these geometries to materials like ceramics.”

Material consistency you can rely on

Other biomimicry studies at McGill have looked at “sutured” materials in nature for ideas about how to toughen otherwise brittle systems, like the complex, rigid sutures joining cranial bones.

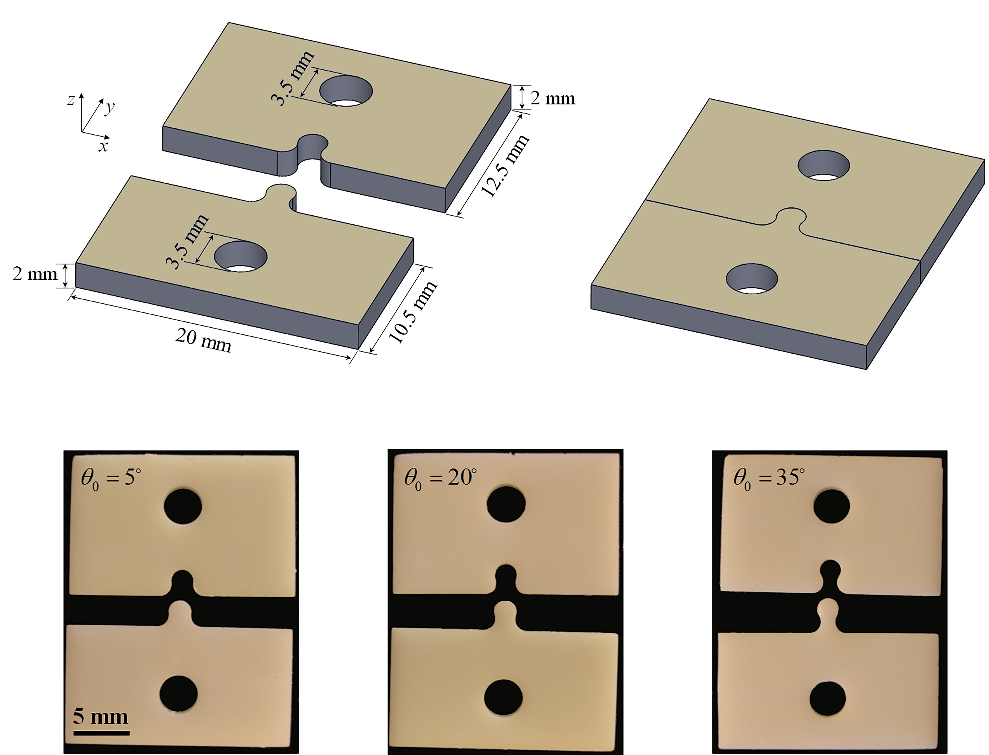

Barthelat and his team modeled the interplay between two rigid plates joined by jigsaw-like interlocking tabs, calculating how much force it would take to pull the plates apart. But actually testing the impact of changing the interlocking angle required 3D printing “puzzle pieces.”

In order to ensure that they were truly testing only the variable in question, such as the interlocking angle, the McGill researches relied on the EnvisionTEC printer to produce segments that were both fully isotropic and dimensionally accurate. They used EnvisionTEC’s Perfactory ABS-like material and, as Barthelat explains, the machine delivered.

“What we really like about the EnvisionTEC printer is that its DLP technology exposes the polymer through a membrane to build a part that is dense, without any pores, and fully isotropic. This means that the stiffness and the strength are the same in all directions, which greatly facilitates the testing and analysis of the 3D printed parts.

“In other technologies we looked at, like fused deposition and other more common technologies building layer by layer, you’re left with cleavage planes, which you see with mechanical testing. In general, if you build your parts along the Z axis, when you try to break the component there will be a cleavage plane across that axis. That’s very bad news, because it makes it extremely difficult to compare your mechanical tests with the model. When things are not isotropic, it complicates the whole story.

“The EnvisionTEC produces material that is really isotropic, so that we could get very good agreements between modeling and experimental data.”

Puzzle pieces with four micron accuracy

Dimensional accuracy was also critical in the McGill team’s research, and again, the 3D printer delivered. “Another thing we really like about the printer is the high resolution,” said Barthelat. “We’re getting plus or minus four microns. So we can print shapes designed to slide perfectly together with no gap in between. We programmed an eight micron gap, which for mechanical testing purposes is essentially in contact, and our parts fit together without any undo force. The polymer shrinks a bit when it cures, so there is a bit of trial and error to determine how best to program the gap at the beginning. But it’s a repeatable process, so you can rely on the same gap between components in all the structures you make.

“The high resolution also relates to the smoothness of the components, which is important to us because we want the parts we make to slide on each other. We do a lot of frictional contact between these parts, whether it’s the bi-stable suture, or the jigsaw kind of suture, or the fish scales. They contact each other but there is also some friction when force is applied to the surface, so we want to make sure that they have uniform friction, independent of surface roughness.

“We’re very happy that the EnvisionTEC produces a roughness that is very uniform. We did a lot of measurements of the friction coefficient between parts produced on the EnvisionTEC to determine this.”

It turned out that after systematically optimizing the tabs, the interfaces with a low coefficient of friction and a high interlocking angle had the best pullout performance.

“The sutured component is 45 times tougher than plain ABS in the pulling direction,” Barthelat said. “It dissipates 45 times more energy and it can absorb 45 times more kinetic energy. Thus it would be superior for impact material. And this is the goal for all impact materials, whether you are using them for cars or buildings: The ability to absorb kinetic energy in the structures that are between the impact and the person you are trying to protect. The sutures we made absorb energy through friction.”

Other materials, other applications

Besides Perfactory, McGill uses other types of photopolymers in the EnvisionTEC potfolio, and Barthelat said McGill plans to make their own materials at some point “tailoring it, possibly adding extra ingredients to reinforce it.”

For now, the research team is already busy exploring how to use 3D printing to expand the locking features of their sutures to mushroom-like features and other surfaces. “Something like Velcro,” he explained, “where you have two surfaces and use the interlocking to generate fastening.”

Barthelat said their team has needed little or no support from EnvisonTEC, other than some consumables. “We may have needed a little software help at the beginning but the machine is ‘plug and play.’ It has a small footprint in the lab. It’s very easy to use. The software is very friendly. We also use MATLAB software to generate our models and STL files with no problems. The EnvisionTEC has been a good experience for us. We’re very, very happy with the machine.”

3D PRINTED BIOMIMICRY AT NORTHWESTERN UNIVERSITY RESULTS IN LIVE BIRTH

Learn more about how a team at Northwestern University mimicked the design of a mouse ovary structure with microporous scaffolds, 3D printed on EnvisionTEC’s 3D-Bioplotter, to successfully create a bioprothetic ovary used in sterile mice, resulting in a live birth.

“Every organ has a skeleton,” said Theresa K. Woodruff, who also is the Thomas J. Watkins Memorial Professor of Obstetrics and Gynecology and a member of the Robert H. Lurie Comprehensive Cancer Center of Northwestern University. “We learned what that ovary skeleton looked like and used it as model for the bioprosthetic ovary implant.”

“This is the first study that demonstrates that scaffold architecture makes a difference in follicle survival,” said Ramille Shah, assistant professor of materials science and engineering at McCormick and of surgery at Feinberg.said. “We wouldn’t be able to do that if we didn’t use a 3-D printer platform.”

The work was published in Nature Communications, May 16, 2017.

This is just one of several medical research papers that uses biomimicry to develop medical solutions. Read even more here.

Above, PhD student Ali Shafiei, left, and Professor Francois Barthelat with the EnvisionTEC Micro Plus Hi-Res 3D printer in the McGill University Laboratory for Advanced Materials and Bioinspiration.