EnvisionTEC High-Speed Continuous 3D Printers Get Fresh Look

This week, EnvisionTEC will be showing off its continuous 3D printing technology for the first time at RAPID + TCT in Pittsburgh, the premier event for 3D manufacturing in North America.

To celebrate how different and exciting our high-speed printing technology is, we’re also unveiling a fresh new look for our 3D printers powered by Continuous Digital Light Manufacturing (cDLM) technology.

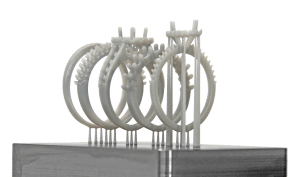

We launched the Micro cDLM in 2016 at the JCK Las Vegas jewelry show, for our loyal customers who have relied on our 3D printers for 15 years. Today, jewelers can 3D print 5-7 custom ring patterns for customers in 15 minutes or less, helping them close sales faster.

Our Vida cDLM, which has an impressive build envelope of 3.54 x 1.97 x 3.94 in., followed in 2017 at LMT Lab Day, a trade show for dental labs.

Today, this super-fast technology means dentists and labs can 3D print 12 dental crowns in 16 minutes in our E-Dent 400 material. What’s more, they are able to create five dental partials with delicate clasps in about 150 minutes, with Z resolution of an impressive 25 microns.

Because our cDLM technology is so fast, cDLM print jobs also require fewer supports and less substantial supports, meaning there’s less post-processing and the ability to print more delicate parts than with other printing technologies. Dental partials are a great example of this.

Our customers in the medical, professional and industrial sectors are truly excited about this technology, and the best part of EnvisionTEC’s cDLM technology is this:

- Our sophisticated cDLM technology, backed by 15 years of experience in 3D printing machines, software and materials, really works reliably,

- We have bigger cDLM printers coming soon, and

- Continuous technology opens the door to amazing new materials that were previously not possible in 3D printing because of slower build speeds.

As photochemistry has evolved, some materials have come along that can deliver superior characteristics when cured by light. But some of these materials have a very short pot life, which means they have to be processed at rapid build speeds, much faster than conventional 3D printers using vat photopolymerization have typically moved.

So, the advent of continuous printing has made these short pot life materials more relevant than before, and that means exciting new materials are on the horizon for manufacturers serving a wide range of sectors.

If you’re going to RAPID + TCT, be sure to stop by EnvisionTEC booth 1813 and see how fast our patented continuous technology can print now. Also join us as we celebrate being #15YearsBetter.