Viridis3D: Robotic Sand Printing a “Game Changer” for Metal Casting

Additive Manufacturing Magazine | November 6, 2017 ~ Looking on the horizon, Viridis3D new sand 3D printing system is expanding options for the foundry’s customers in areas including legacy tooling, product development and design complexity.

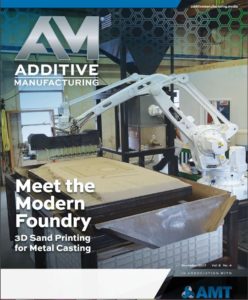

Today, Hazleton Casting Company (HCC) is using the future of industrial foundry operations – Viridis3D’s RAM 123 robotic additive manufacturing technology.

The Viridis3D RAM123 robotic sand printer— is a “game changer,” as HCC President Tony Badamo calls it. Currently, HCC is using the Viridis3D machine to print molds and cores straight from a digital model into a bed of sand, without any need for a pattern or core box.

Viridis3D’s disruptive technology brings a new way of production to foundries — instead of shipping castings around the world, raw materials are shipped and files are simply transmitted to 3D printers in strategic locations. The result is castings are poured the same day.

For more information about Viridis3D robotic additive manufacturing system, contact Peter Denmark at pdenmark@envisiontec.ciwebstudio.com in the Americas and Sobhi Aris at sobhi.aris@envisiontec.de in Europe, Asia or elsewhere. Or, call the Viridis3D office in Woburn, Mass., at 781-305-4961.