Carbon Nanotube-Filled, Bone Material Bioprinted with EnvisionTEC 3D-Bioplotter Holds Great Promise for Implants

How do you 3D print a bone? A couple of years ago, if anyone who was not a researcher (and even many researchers) asked this question, people might have looked at them in a weird way. Today we know: it takes a a combination of a resorbable – such as a biodegradable polymer – and an inorganic bioactive phase material – such as ceramics.

The research group led by Prof. Maria Vallet-Regí at the faculty of Pharmacy-Universidad Complutense de Madrid (Spain) recently showed that if you add carbon nanotubes to the mix to create a 3D electrical network within the bone tissue you can actually stimulate bone cell regrowth. To prove it they used an EnvisionTEC 3D-Bioplotter® and published the results, in collaboration with the University of Aveiro (Portugal), on the Journal of Biomedical Materials Research.

The research group led by Prof. Maria Vallet-Regí at the faculty of Pharmacy-Universidad Complutense de Madrid (Spain) recently showed that if you add carbon nanotubes to the mix to create a 3D electrical network within the bone tissue you can actually stimulate bone cell regrowth. To prove it they used an EnvisionTEC 3D-Bioplotter® and published the results, in collaboration with the University of Aveiro (Portugal), on the Journal of Biomedical Materials Research.

The polymer they used is a material that is rather easy to 3D print and that was FDA approved for use in implants: polycaprolactone, or PCL. The ceramic phase material is hydroxyapatite, a commonly occurring calcium based mineral.

“Nowadays, calcium phosphates, glasses, and polymers are widely used as bone regenerators and biocompatible functional materials in tissue engineering, as they are very similar to the natural bone tissue,” said Mercedes Vila, the Principal Investigator in charge of the project. “These types of materials are designed with different shaping methods for obtaining implant pieces and scaffolds with the required shapes and sizes.”

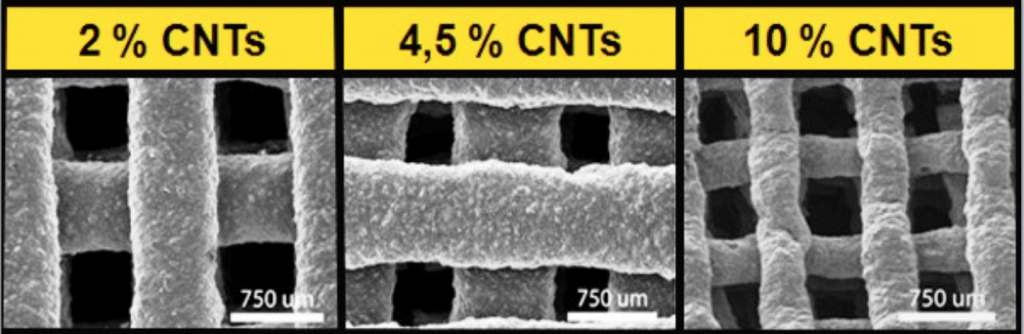

“The carbon nanotubes (or CNT’s) were added to the bioprintable material mixture to create a “three dimensional electrical conducting network all through the volume of the scaffold, which would allow the application of this stimulation to the scaffold once implanted on the damaged bone site.”

The reason for this, Mercedes explained to me, is that modern techniques tend to combine robust materials with smart systems able to respond to external stimuli to accelerate the osteointegration (bone regrowth) process. In case you don’t know what they are, CNT’s are basically one -atom-thick graphene sheets rolled up onto themselves in order to form very long filaments with diameters of only a few nanometers.

“In this sense, electrical stimulation has been explored since the discovery of the presence of electrical potentials in mechanically loaded bones,” Mercedes pointed out. “Certain types of cells behavior, such as adhesion and differentiation, can be affected by the application of electrical stimulation. Thus, the creation of a permanent charge on the material surface, positive or negative, as well as a direct electrical stimulation can promote the attraction of charged ions from the environment to the cells. This would modify their protein absorption with the subsequent influence on the cells metabolic activity. Therefore, the use of electrical stimulation after biomaterial implantation to favor cell adhesion and differentiation and, consequently, induce bone healing seems a smart approach to accelerate the osteointegration process.”

This basically means that by adding conducting CNT’s into the bioprinted polymer and mineral prosthetic bone implant, you can stimulate the regrowth of the actual bone cells. This, of course, now takes place only at an in-vitro and cellular level but the road is clear. Perhaps one of the most curious aspects is that bioprinting CNT’s created no additional difficulties as they are so thin that the can be extruded with ease through any pneumatic syringe. Most of the complications are related to finding the right viscosity in the combination of CPL and hydroxypatite.

“Finding the right viscosity to be extruded through the syringe while keeping enough robustness to get the 3D scaffold printed at room temperature, was complicated,” Mercedes admitted. “At the same time as the slurry was prepared in dichloromethane solution for diluting the PCL, the achieving of the right viscosity while evaporating of the solvent was tricky. Moreover, once the PCL and the hydroxyapatite where mixed together the addition of the CNTs was performed and reaching a proper dispersion took a bit of stirring time.”

Mercedes and the team are enthusiastic about the possibilities offered by bioprinting. They have been working on the design of bioceramic-based bone grafting materials and scaffolds for regenerative biomedicine that will speed up bone regrowth while the polymer-based support dissolves efficiently. These research lines involve also the production and study of bioceramic systems for controlled release of biotechnological and antitumoral species, nanoparticles and biocompatible matrices for biotechnological applications. Moreover they are pioneers on the application of silica based ordered mesoporous materials as release systems of biologically active species, cell encapsulation in silica porous materials, mesoporous materials for gene therapy and transfection, organic-inorganic hybrid materials.

Using EnvisionTEC’s 3D-Bioplotter they were able to take their research to new levels, creating very complex multilateral 3D structures following specific designs previously programmed on the computer. “This is an incredible advantage when trying to produce bone substitutes as the bone defects to fill in are highly variable depending on each case,” Mercedes explained. “I believe that this technique is the future for tissue replacements as it allows tailored solutions by capturing the anatomical information of the patient’s wound by computed tomography and magnetic resonance, for example, to obtain a personalized and unique implant. There is already a large trend being developed for introducing and testing these products as future solutions and I think we will see them on the market shortly.”

As with many other 3D printing applications it seems we are only beginning to scratch the surface of the possibilities that lie ahead but all the signs are there that bioprinting is one of the ways – if not the best way – to go forward in many – if not all – regenerative medicine applications.