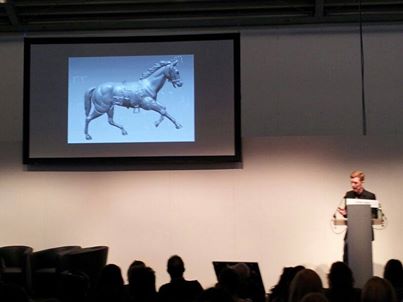

TCT team selects candidates from among 3D printing’s most powerful global executives to deliver their personal insights during exclusive keynote addresses. For 2015, EnvisionTEC CEO Al Siblani was chosen to be the opening keynote presenter of the TCT Show + Personalize. Recognized as a pioneer within the 3D printing industry, Al shared his history, his thoughts on the current impact of 3D printing on the global economic playing field, and his vision of the potential 3D printing and EnvisionTEC offer to the future to a crowded room.

For those unable to attend, we would like to share this opportunity to see the presentation and congratulate Mr. Siblani on being an inspiring example of thought leadership among the 3D printing community and to the global EnvisionTEC team.

TCT Show + Personalize is one of the world’s leading events dedicated to 3D printing, additive manufacturing, and product development. This September marked the TCT Show’s 20th anniversary and attendance for this special event hit record numbers. EnvisionTEC has been a long-time exhibitor at this prestigious 3D technologies event in the UK, and our commanding presence this year confirmed our place as one of the biggest names in global 3D printing.

Atlanta Jewelry Show

EnvisionTEC is sponsoring an exciting design contest where the winner can walk away with their choice of $500 CASH or $2000 off the price of a brand new EnvisionTEC Micro 3D Printer!

Bring an STL file of your hottest new design on a flash drive to the EnvisionTEC Booth 1528, between 10am and 2pm on Saturday, August 8, 2015.

EnvisionTEC will be 3D printing the designs right there on the show floor to introduce their brand new QView material. This exciting new material is capable of impressive print speeds of up to an inch an hour for the full build envelope at 50 µm resolution. This allows designers to put their custom design pieces into their customers hands in record time for final fit and design verification. The entries will be showcased throughout the Atlanta Jewelry Show at the EnvisionTEC booth.

An expert panel of judges will be judging the completed pieces and the winner will be announced

Monday, August 10, 2015, at 1pm in Booth 1528.

Rules:

- One entry per designer.

- Entry must be in .STL file format, delivered to Booth 1528 during the specified time.

- Designer MUST be present to win.

- Entries will be judged on creativity, complexity of design, final aesthetics, and ease of manufacturing.

- Design may be used by EnvisionTEC for marketing purposes with credit to be given to the designer.

Good luck and we look forward to seeing your best designs!

We look forward to seeing you this weekend at the Atlanta Jewelry Show. Stop by to see the entries and some groundbreaking new products you definitely won’t want to miss!

Solidworks World

EnvisionTEC went to Solidworks World at the Phoenix Convention Center in Arizona February 8-11. Solidworks is an exclusive technology partner, and EnvisionTEC had the pleasure of presenting the latest 3D printing innovations in booth S401.

EnvisionTEC went to Solidworks World at the Phoenix Convention Center in Arizona February 8-11. Solidworks is an exclusive technology partner, and EnvisionTEC had the pleasure of presenting the latest 3D printing innovations in booth S401.

Solidworks World 2015 was a very productive meeting of the 3D printing industry’s innovators. The event attracted designers, engineers, and consumers interested in the “revolution” of 3D printing and where the industry will go next. The event fostered an open conversation about 3D printing through #SWW15 tagging and daily live streams of speakers and demonstrators.

PDM

EnvisionTEC manned booth #3609 at the PDM Expo February 10-12 at the Anaheim Convention Center in California. The PDM show brings together the best of the best in a variety of design and manufacturing fields, while presenting up-and-coming innovation for the latest processes and applications.

EnvisionTEC manned booth #3609 at the PDM Expo February 10-12 at the Anaheim Convention Center in California. The PDM show brings together the best of the best in a variety of design and manufacturing fields, while presenting up-and-coming innovation for the latest processes and applications.

EnvisionTEC was proud to participate in the latest developments in 3D printing covered at the show. The team shared an overview of our manufacturing 3D printers and  accompanying 3SP technology, as featured in the ULTRA® 3SP Family and Large Frame 3SP printers, and DLP technology, found in the Perfactory® series.

accompanying 3SP technology, as featured in the ULTRA® 3SP Family and Large Frame 3SP printers, and DLP technology, found in the Perfactory® series.

EnvisionTEC had a wonderful time at both of these MCAD and CAM events. The team is looking forward to participating in both the Solidworks World 2016 show and the Pacific Design & Manufacturing Expo in 2016. Thank you to all the attendees, partners, and organizers who made these shows a success!

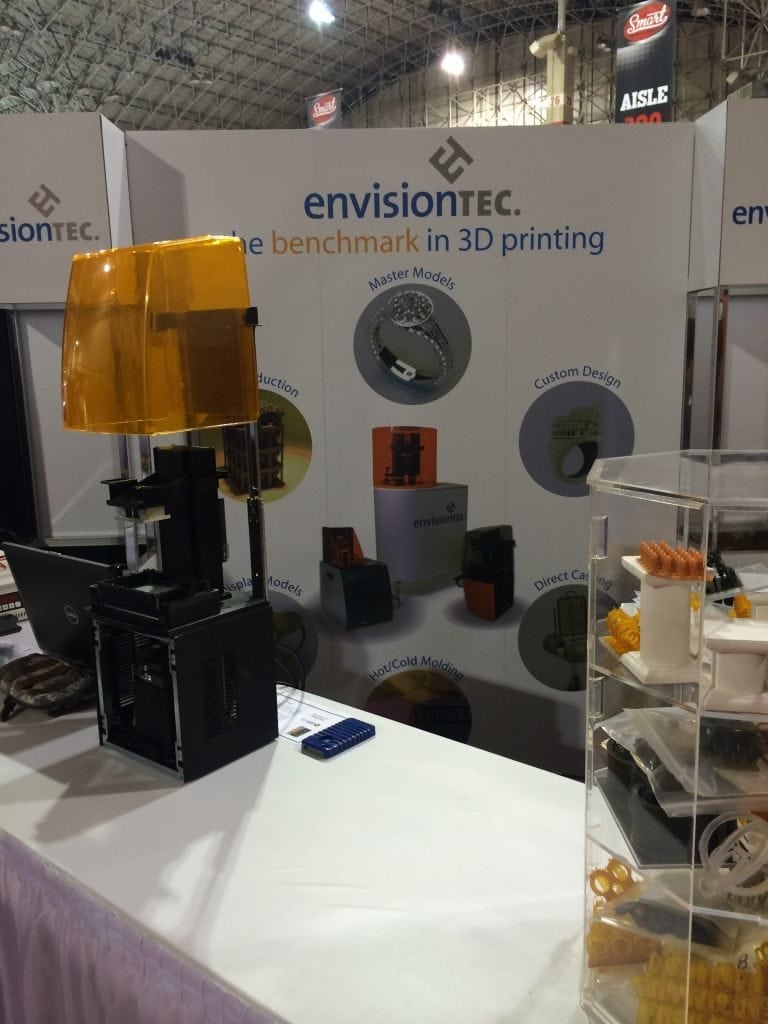

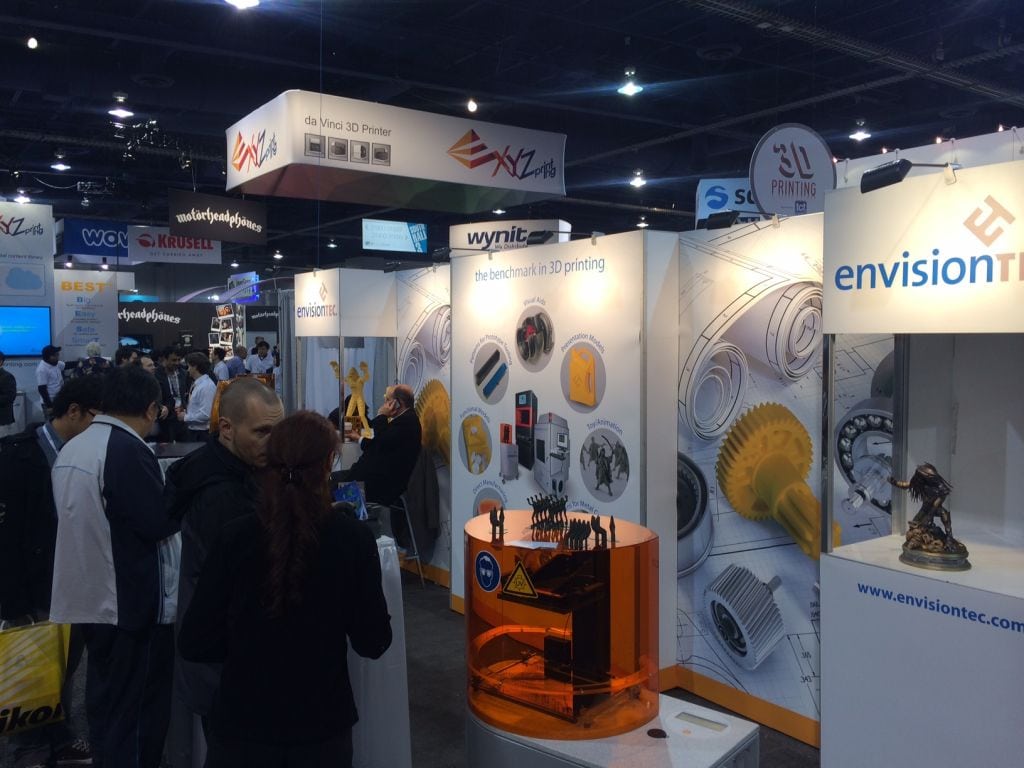

CES

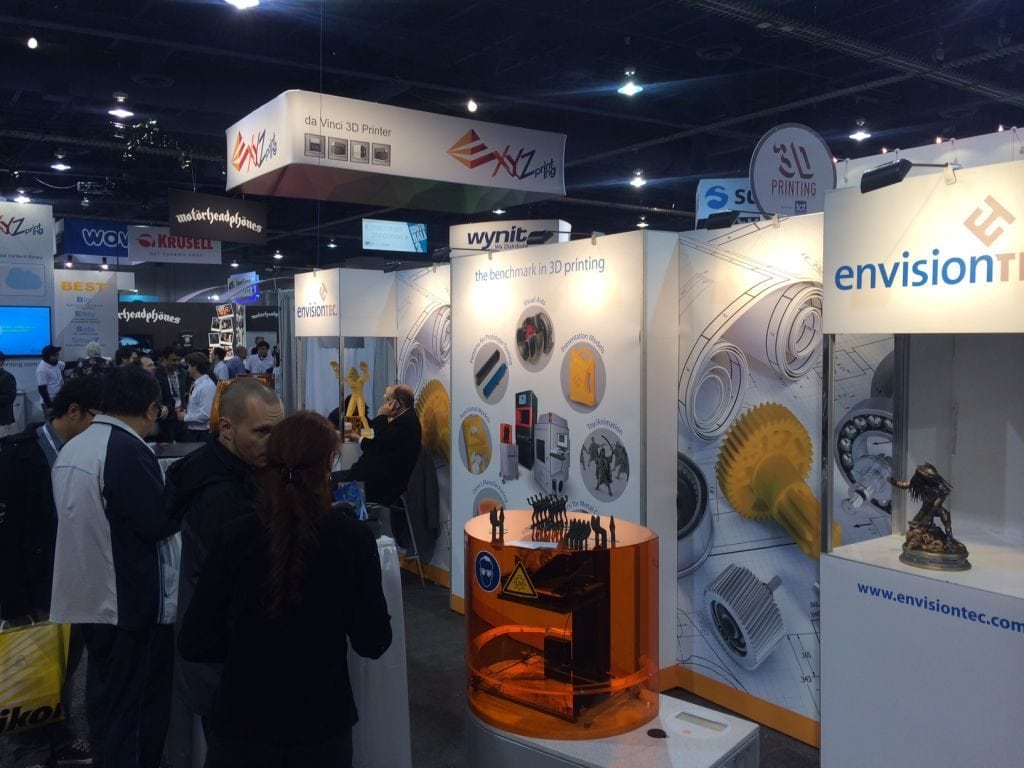

The yearly Consumer Electronics Show, held in Las Vegas, Nevada. The CES intends to bring together the latest technological innovations across industries for the modern tech-savvy consumer. As a multinational 3D printer manufacturer directly participating in professional manufacturing and supply chain production, EnvisionTEC was pleased to form part of the 3D printing exhibitor’s list in the Sands Expo.

This year’s CES was a huge success. Event attendees numbered at 170 thousand, exceeding projections of 160k. The 3D Printing section in particular was packed with exhibitors and visitors alike. Based on the amount of traffic on CES’s 3D printing floor as well as projected growth in technology and products for the industry, next year’s show will likely have to grow to accommodate burgeoning numbers of users and providers of this cutting-edge process.

This year’s CES was a huge success. Event attendees numbered at 170 thousand, exceeding projections of 160k. The 3D Printing section in particular was packed with exhibitors and visitors alike. Based on the amount of traffic on CES’s 3D printing floor as well as projected growth in technology and products for the industry, next year’s show will likely have to grow to accommodate burgeoning numbers of users and providers of this cutting-edge process.

CES is named for consumers, and certainly many consumers had questions about 3D printing. Many attendees like James and Wendy Kawa wandered the 3D printing floor to educate themselves on the different types of technology available from 3D printing, from fused filament fabrication (FFF), to stereolithography (SLA) before finally learning about DLP® chips in EnvisionTEC’s Perfactory® systems. Many event attendees were impressed by the surface quality achieved with EnvisionTEC’s 3D printers, especially in comparison to the finished builds off other machines at the show.

EnvisionTEC brought a range of machines from several of its family systems, including a Perfactory®, a Micro, and an ULTRA® 3SP®. View our 3D Printer Overview to catch a glimpse of what you may have missed in professional 3D printers at CES 2015.

EnvisionTEC is looking forward to participating in next year’s show, especially the 3D printing exhibition, in 2016.

The EnvisionTEC staff at CES 2015

EnvisionTEC had many exciting product releases at EuroMold 2014. In addition to the Xtreme, EnvisionTEC also announced a new line of 3D printer materials as well new Perfactory 3.0 software. The updated Perfactory 3.0 software offers greater reliability and speed. Larger builds are easier to work with and the software also handles files more quickly. Perfactory 3.0 also offers one-click “smart” supports that build correct supports for the build’s dimensions and geometry. The Xtreme offers a large build envelope along with EnvisionTEC’s patented 3SP process. The Xtreme at this year’s EuroMold was the first unveiling of this addition to EnvisionTEC’s 3SP family of 3D printers. Last but not least, EnvisionTEC officially announced a host of new materials for 3SP, Perfactory and Micro printers. These resins are durable and tough upon curing with added flexural strength, while exhibiting the crisp detail that EnvisionTEC 3D printer systems are known for. Intended for multi-use, the new ABS-like materials are well suited to drilling and tapping as well as snap-fit assemblies.

EnvisionTEC participated in the annual Specialty Equipment Market Association (SEMA) Show, November 4 – 7, 2014 in Las Vegas, NV. EnvisionTEC was in Booth #24818 and presented our latest 3D printing innovations.

EnvisionTEC participated in the annual Specialty Equipment Market Association (SEMA) Show, November 4 – 7, 2014 in Las Vegas, NV. EnvisionTEC was in Booth #24818 and presented our latest 3D printing innovations.

EnvisionTEC sent two of our regional sales managers to the event and the EnvisionTEC CEO also attended. Hratch Gasparyan, the Channel Sales Manager for the West Coast, and Rich Scherer, the Midwest Channel Sales Manager, ran the booth. Both have specialized information on EnvisionTEC products and technology. They met with engineers, designers, and representatives from a good deal of businesses and companies.

EnvisionTEC brought its offerings for manufacturing and automotive industries. The ULTRA 3SP was on display and running, and there were small benchmark pieces available from the Micro EDU as well. Several companies use the smaller build plate and fine detail of the Micro for small pieces such as buttons and knobs. The ULTRA 3SP creates larger, durable, and functional parts.

Inside 3D Printing

Please join EnvisionTEC at Inside 3D Printing Conference and Expo: Santa Clara, CA, October 21 – 23, 2014. We´d like to welcome you to booth #300 and look forward to presenting our latest 3D printing innovations for MCAD applications.

Please join EnvisionTEC at Inside 3D Printing Conference and Expo: Santa Clara, CA, October 21 – 23, 2014. We´d like to welcome you to booth #300 and look forward to presenting our latest 3D printing innovations for MCAD applications.

See more on EnvisionTEC’s solutions for MCAD processes using 3D printers.

EnvisionTEC West Coast Channel Sales Manager Hratch attended the conference with the Midwest Channel Sales Manager Rich. They brought the ULTRA 3SP and the Micro EDU to the show, demonstrating two of EnvisionTEC’s core technologies. Both the 3SP capability of the latest ULTRA and the DLP technology featured in the Micro are excellent for prototyping, modeling, snap-fit assemblies, housing units, injection molding, patterns for casting and end-use parts.

EnvisionTEC exhibited at the 2014 Biomedical Engineering Society (BMES) Annual Meeting from October 22 to the 25, 2014 in San Antonio, Texas. We´d like to welcome you to Booth #304 and look forward to presenting our latest 3D printing innovations.

EnvisionTEC exhibited at the 2014 Biomedical Engineering Society (BMES) Annual Meeting from October 22 to the 25, 2014 in San Antonio, Texas. We´d like to welcome you to Booth #304 and look forward to presenting our latest 3D printing innovations.

EnvisionTEC’s rapid prototyping tool for tissue engineering is the Bioplotter. Our in-house expert, Dr. Carlos Carvalho was at the BMES running the Bioplotter and answering questions on how the technology works. Channel Sales Managers Peter and Paul were also on hand to assist with any questions. See published bioprinting research using the 3D-Bioplotter.

EnvisionTEC is attending the 3D Print Expo 2014, October 23 to the 25, 2014 in Moscow, Russia. We exhibited along with our distributors Nissa Digital and Cybercom at the ECC “Sokolniki” and presented our latest 3D printing innovations there for MCAD and industrial manufacturing sectors.

EnvisionTEC attended the Hong Kong Electronic Fair (Autumn Edition) 13-16 October 2014 at the Hong Kong Convention and Exhibition Centre. We presented together with our distributor Bolee Machine Tool Limited there and presented our latest 3D printing innovations in the “Digital Imaging” zone.

EnvisionTEC attended the Hong Kong Electronic Fair (Autumn Edition) 13-16 October 2014 at the Hong Kong Convention and Exhibition Centre. We presented together with our distributor Bolee Machine Tool Limited there and presented our latest 3D printing innovations in the “Digital Imaging” zone.

EnvisionTEC attended the EUHA this week, also known as the 59th International Congress of Hearing Aid Acousticians, October 15 – 17, 2014 in Hannover, Germany. We presented our latest 3D printers for the hearing aid market, including the Perfactory DSP, Perfactory DSP XL, DDSP, Micro DSP in Messe Hanover.

EnvisionTEC is at the International Expodental the rest of this week from October 16 to the 18th in Milan, Italy. We´d like to welcome you and share our 3D dental printing offerings at Fiera Milano City.

EnvisionTEC is at the International Expodental the rest of this week from October 16 to the 18th in Milan, Italy. We´d like to welcome you and share our 3D dental printing offerings at Fiera Milano City.

The DDS – Digital Dentistry Show highlighting digital dental production is also being launched at this year’s International Expodental Milan. Digital dental technology information is throughout this exposition in the forms of lectures, workshops, product presentations, and of course exhibitors like EnvisionTEC.

The International Manufacturing Technology Show 2014 is less than a week away! The industrial trade show is held biannually in Chicago, and EnvisionTEC couldn’t be more excited to be participating in this year’s event with our MCAD 3D printing solutions.

The IMTS historically brings together many industrial fields. These include process, factory automation, building construction, motion automation and more. As an original equipment manufacturer of professional-grade 3D printers, EnvisionTEC has many offerings to bring to the industrial sphere.

EnvisionTEC’s professional grade 3D printers are well-suited to a variety of applications including MCAD projects. The accuracy, speed, and above all, functionality of parts grown on EnvisionTEC 3D printers are proven to refine prototyping processes and get workflow on track.

EnvisionTEC’s professional grade 3D printers are well-suited to a variety of applications including MCAD projects. The accuracy, speed, and above all, functionality of parts grown on EnvisionTEC 3D printers are proven to refine prototyping processes and get workflow on track.

See EnvisionTEC’s solutions for MCAD applications.

In addition to presenting several of our machines at IMTS, EnvisionTEC will also be introducing a range of new products. EnvisionTEC has been developing a group of new materials for manufacturing and design applications to run on our 3D printers. Be on the lookout for our upcoming ABS program — we can’t wait to show it to you.

In addition to presenting several of our machines at IMTS, EnvisionTEC will also be introducing a range of new products. EnvisionTEC has been developing a group of new materials for manufacturing and design applications to run on our 3D printers. Be on the lookout for our upcoming ABS program — we can’t wait to show it to you.

Finally at the IMTS show will be two of our core technologies. DLP® is found in our Perfactory® line of 3D printers, while 3SP® (Scan, Spin and Selectively Photocure) is our latest cutting-edge process for the future of 3D printing.

Our patented digital light processing technique is an example of the great quality and high-functionality of EnvisionTEC parts. Meanwhile, our 3SP line of 3D printers offer high resolution large-frame solutions for the rapid prototyping engineering and design team. The ULTRA 3SP will be on display printing MCAD parts at the IMTS.

TCT Show in the UK — EnvisionTEC was in booth C16 with the Xede® 3SP® and sought to teach attendees more about how cutting edge technology like 3D printing can change the way they bring their products to market. We brought great examples of products that have gone from prototype to finished realization in record time alongside the 3D printers that got results.

EnvisionTEC attended the TCT Show, September 30 – October 2, 2014 in Birmingham, UK. We were very excited to present to our audience in the industry in Booth #C-16.

EnvisionTEC attended the TCT Show, September 30 – October 2, 2014 in Birmingham, UK. We were very excited to present to our audience in the industry in Booth #C-16.

EnvisionTEC supports specific solutions for specific verticals. At the TCT Show this year we presented in four key areas of applications:

1. M-CAD

2. Toys, models and sporting goods

3. Luxury items

4. Medical applications

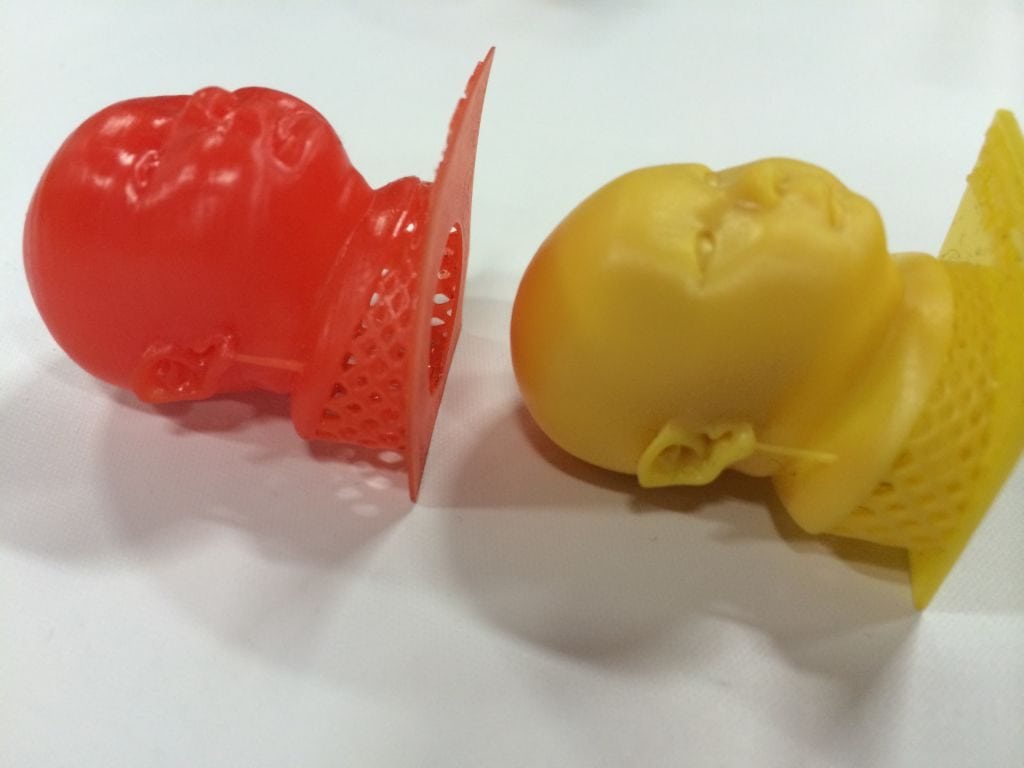

For MCAD, EnvisionTEC brought a 3D printed coffee makers. Among the models were two representations of famous German politicians from the Restoration era Chancellor Konrad Adenauer and Erich Honecker. EnvisionTEC Europe also hosted a golf putting competition with samples from Cleveland Golf, a client who uses an ULTRA® 3SP® in their research and development process. There were also samples from the 3D-Bioplotter®, hearing aids and dental models.

EnvisionTEC brought a host of machines to this year’s TCT show. First and foremost was the Xede® 3SP®, one of EnvisionTEC’s large-frame industrial printers with 3SP® technology. The booth also ran 2 ULTRA® 3SP® machines to round out its MCAD offering. In addition, the booth showed Perfactory® 4 machines, Apollo, Desktop XL, Micro EDU, Micro Advantage and a Micro HiRes.

EnvisionTEC had a great time seeing old clients and making new contacts in the 3D printing world. We also loved seeing our friends at TCT at their great event billed as “the largest 3D printing expo in the world”! We can’t wait to come around again next year!

If you had some questions from the show — or if you didn’t get to attend — contact us today!

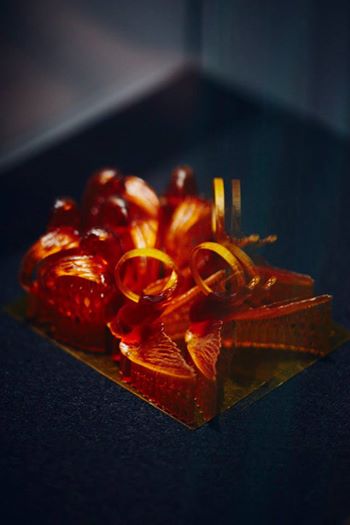

- 3D printed luxury items at TCT 2014

- EnvisionTEC at TCT 2014

The EnvisionTEC booth at TCT 2014

The BIO International Conference & Exhibition took place June 23-26. This year’s show, BIO 2014, was held in California at the San Diego Convention Center with over 2,000 exhibitors present an array of emergent and established technologies such as pharmaceuticals, medical devices, biomanufacturing, nanotechnology, stem cell research, and drug delivery, to name a few. BIO 2014 hosted attendees from biotechnological firms, pharmaceutical companies, and hundreds of academic institutions and research labs.

Carlos at BIO 2014

EnvisionTEC’s Process & Material Development engineer Carlos Carvalho brought the 3D-Bioplotter® to BIO 2014. The Bioplotter® is a rapid prototyping biomedical engineering tool that manipulates biomaterials with the aid of 3D data into a physical scaffold with a defined outer form and an established inner structure. The 3D-Bioplotter® is designed for work in sterile environments in a laminar flow cabinet and is suited for applications including bone regeneration, controlled drug release, soft tissue or organ printing, and concept modeling. The Developer Series can work with two materials at a time, with an optional third cartridge upgrade. The 3D-Bioplotter® Manufacturer Series features five cartridges, a sterile filter, as well as heating and cooling on the build platform. Both series offer needle position control, automatic z-vector controlling for changeable platforms such as petri dishes, and an automatic nozzle cleaning process.

3D-Bioplotter

The 3D-Bioplotter® can process a wide variety of biomaterials suited for a range of applications, including hydroxyapatite , chitosan, gelatin and agar. The printing method employed by the 3D-Bioplotter® is deposition of material in the x, y, and z vectors through pressure distributed by the syringe nozzle. When the pressure is applied through the active printer head, a strand of material deposits for the duration of movement. The system deposits parallel strands rotating 180 degrees for each layer to produce the lattice structure as seen below.

EnvisionTEC had the pleasure of participating in the RAPID Conference & Exhibition in Detroit this week from June 9-12. EnvisionTEC has been looking forward to this event, which took place in right in our backyard at the Cobo Convention Center in downtown Detroit. We had a host of staff at the event, including most of our technicians, sales managers and marketing team.

The EnvisionTEC staff at the Cobo Center

The Xede® 3SP® exhibited for the first time in the United States at RAPID. The 18” x 18” x 18” build envelope makes this printer the largest in the EnvisionTEC family, and its specialized 3SP resins make it an excellent choice for building large CAD parts. The 3D-Bioplotter® Developer Series was also on display, continuing its North American exhibition run. Dr. Carlos Carvalho from Process & Material Development is EnvisionTEC’s in-house expert on the bioprinter and tissue engineering. Dr. Carvalho answered questions on the machine’s functions and applications while running a deposition demonstration of its process.

Two EnvisionTEC clients from the medical field spoke at the convention. Both David Dean, Ph.D, who runs his lab at Ohio State University, and Dr. Ramille Shah, head of SHAH Lab at Northwestern University, use EnvisionTEC equipment for their research. Dean spoke on the use of additive manufacturing for surgical guides and implants, work he has extensively conducted using a Perfactory® Series 3D printer. Dr. Shah presented her research developing hyperelastic bone scaffolding. The Bioplotter features prominently in SHAH Lab’s research due to the bioprinter’s unique scaffolding-deposition technique.

Dr. Ramille Shah, Professor at Northwestern University, gives her presentation on hyperelastic bone substitute developed on the 3D-Bioplotter®

From the arts and entertainment spheres, Scott Wetterscheider (Shinbone Creative) spoke on behalf of our friends at Morpheus Prototypes who service toy manufacturers, digital illustrators and character designers with an Xede 3SP and a Perfactory® Micro. Finally, Scott Lopes from the acclaimed Legacy Effects gave a keynote presentation on using 3D printing for blockbuster films, including Iron Man, Robo Cop, and Avatar. Legacy Effects own a Perfactory Series 3D printer.

EnvisionTEC also participated in the scavenger hunt thrown by SME in which event attendees were invited to collect 3D printed “puzzle pieces” from several event vendors. We caught up with a distributor, Cam Logic, who 3D printed their scan of the Spirit of Detroit with an ULTRA 3SP printer.

Finally, much to our delight and appreciation, EnvisionTEC won the distinction of “Best in Show” this year! The last day of the show the SME awarded EnvisionTEC with a 3D printed and metal-plated statue.

Finally, much to our delight and appreciation, EnvisionTEC won the distinction of “Best in Show” this year! The last day of the show the SME awarded EnvisionTEC with a 3D printed and metal-plated statue.

EnvisionTEC attended the JCK Show in Las Vegas this year from May 30th to June 2 — we had a very memorable and successful time presenting our 3D printing innovations for jewelry makers — the Nevada show had 55,000 attendees, one of the largest attendances yet for 2014.

EnvisionTEC CEO Al Siblani attended the JCK Show along with channel sales manager Hratch, Micro technician Don, head service and applications technician Bill as well as EnvisionTEC’s head of North American jewelry sales. EnvisionTEC presented the Perfactory® 4 Mini, the Micro Hi-Res, the Micro Advantage and the newest 3D printer for the jewelry market, the Perfactory® Apollo. The team was very busy demonstrating the high resolution and accuracy of EnvisionTEC 3D printers for jewelry, and were very excited to unveil the Apollo midway through the show.

- Bill (left) and Hratch (right) speak to event attendees

- Bill head of North American jewelry sales at the EnvisionTEC booth

- Two different results from a competing technology (left) and an EnvisionTEC 3D printer (right)

- the EnvisionTEC Difference

An EnvisionTEC customer’s booth!

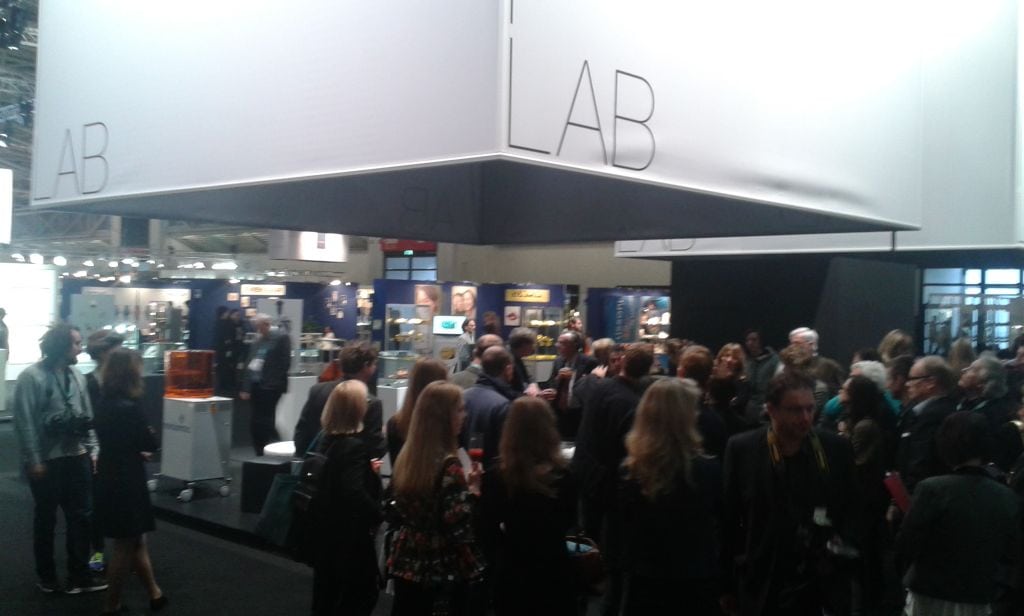

The exhibit portion of Lab Day West took place May 17th in California. EnvisionTEC was excited to participate in an event close to our Gardena, CA, facility as well as to introduce several 3D printing solutions for dental laboratories.

EnvisionTEC CEO Al Siblani attended, along with channel sales manager Hratch and Service and Applications technician Mike. According to an LMT research poll published in the May 2014 issue of LMT Magazine, 27% of laboratories fabricate their own digital models, while three quarters outsource the work to another manufacturer. Most of the attendees at Lab Day West were laboratory owners looking to either add more 3D printing technology to their current lineup or bring their production in-house.

EnvisionTEC brought along the 3Dent™, the Perfactory® Micro DDP (which stands for Digital Dental Printer, and the newest machine in the Perfactory® Micro Family, the Micro Drill Guide Printer. The Micro Drill Guide Printer or Micro DGP is a printer developed specifically for use in 3D printing drill guides for use in surgery. These drill guides in America are printed by Terry Fohey of NuCraft Dental Arts in Atlanta.

The Micro DDP, another desktop-sized 3D printer from EnvisionTEC, produces crowns, copings and temporaries from digital files. The DDP produces crowns and copings from Press-E-Cast, a wax-filled photopolymer with low thermal expansion, great surface finish, and superior stiffness which allows for copings with thin margins. Copings or crowns made from Press-E-Cast can then be pressed or cast for precise results. The Micro DDP builds temporaries out of the E-Dent material, available in three shades and FDA-approved for wear of up to a year in the mouth.

- Drill Guides on a Micro

- Hratch demos EnvisionTEC for Lab Day West attendees

- Copings in Press-E-Cast

Read the case study here on NuCraft Dental Arts’ 3D printed drill guides.

Solid Edge University 2014 took place May 12-14th in Atlanta, Georgia. SEU is sponsored by Siemens and is an event for industry members, affiliates, tech and industrial spheres to connect.

Solid Edge University expands product knowledge about Solid Edge for 3D designers and connects them to showcases of peripheral units likelike 3D printing from EnvisionTEC. Solid Edge from Siemens PLM Software is a 3D CAD parametric feature modeling software which provides a variety of MCAD functions for engineers and designers including drafting, modeling of assemblies and product lifestyle management (PLM) that Siemens is known for. Solid Edge is cross-compatible and can be integrated into the product cycle– not only can Solid Edge be used with other software but it can also be used in conjunction with EnvisionTEC 3D printers.

At the event in Atlanta, EnvisionTEC’s Director of Channel Sales Andy and Andrew, Channel Manager for the Southeast, helmed the EnvisionTEC booth. Andy and Andrew formed a great team beyond their shared name — they met many Solid Edge team members and forged new contacts with event attendees. The EnvisionTEC sales duo had the pleasure of speaking with a wide variety of Solid Edge users, including an engineer working on a project on automotive fuel-efficiency as well as members from Ditch Witch vacuum excavating equipment.

At the event in Atlanta, EnvisionTEC’s Director of Channel Sales Andy and Andrew, Channel Manager for the Southeast, helmed the EnvisionTEC booth. Andy and Andrew formed a great team beyond their shared name — they met many Solid Edge team members and forged new contacts with event attendees. The EnvisionTEC sales duo had the pleasure of speaking with a wide variety of Solid Edge users, including an engineer working on a project on automotive fuel-efficiency as well as members from Ditch Witch vacuum excavating equipment.

The American Association of Orthodontists® is an official organization for certified orthodontic practitioners. About 95% of orthodontists hold membership in the organization, which sponsors meetings and events as while as fostering education and research. The AAO is deeply associated with the orthodontic community and also shares orthodontic news and professional publications on the industry.

The 2014 annual AAO meeting took place April 25-29 in New Orleans. EnvisionTEC sales rep Hratch along with technicians Mike and Hadi attended as well as EnvisionTEC CEO Al Siblani. EnvisionTEC brought its latest answers for orthodontic appliances, the ULTRA® 3SP® Ortho and the Perfactory® Micro Ortho.

The Micro Ortho speeds up the model-making process without sacrificing the quality and functionality that EnvisionTEC is known to deliver. This printer has an envelope of 100 x 75 x 100 mm and can complete 3 full arches face-up in 45 minutes , or up to 7 models face-down in under 4 hours. The average cost for each full arch produced on the Micro Ortho is less than five dollars. The materials for this printer offer a high-quality surface finished which yields a snap-fit in finished appliances, while their high-temperature resistance reduces distortion from clear aligner production. The Micro Ortho has a machine footprint of 11” x 10” x 24” for desktop use and can be plugged into your computer via USB.

It was great meeting all of the AAO visitors — EnvisionTEC is excited to attend the San Francisco session in 2015.

- Hratch speaks with visitors.

- ET’s Micro Ortho demo

- CEO Al Siblani and the ULTRA® 3SP® Ortho.

EnvisionTEC attended this year’s Materials Research Society Spring Meeting in San Francisco. The Materials Research Society is an organization dedicated to bringing together materials research in order to improve quality of life. Changing quality of life for the better is an important mission for EnvisionTEC and we were honored to take part in this year’s MRS event.

EnvisionTEC shared our commitment to groundbreaking research in the medical and health fields at the MRS. EnvisionTEC’s latest system for bioprinting is the 3D-Bioplotter® , a platform for tissue engineering development and research.

The 3D-Bioplotter® has been in use by several top research labs and universities. These institutions are searching for health and medical solutions. Shah Lab, headed by Dr. Ramille Shah, researches tissue engineering using 3D printing at Northwestern University. The team uses the 3D-Bioplotter® to create and develop the use of human biological scaffolds. Shah Lab experiments with materials like bone or cartilage that can be implanted in order to allow tissue to regenerate itself in the human body.

With the addition of the Developer Series, the 3D-Bioplotter® now comes in two versions to meet the needs of different user groups (and their budgets). The 3D-Bioplotter® Developer Series is ideal for the exploratory and experimental requirements of educational institutions, while the 3D-Bioplotter® Manufacturing Series is suited for advanced tissue engineering research and production.

The 3D-Bioplotter was first used by Dr. Natalja E. Fedorovich, et. al, to 3D print live cells in 2004. More research using the Bioplotter can be accessed here and here.

This year’s Additive Manufacturing Users Group (AMUG) conference took place in Tucson, Arizona, April 6-10. AMUG is an industry-wide educative event that promotes 3D printing technologies as well as their applications.

EnvisionTEC channel sales managers Andy and Alfredo represented the EnvisionTEC booth and welcomed many industry professionals and 3D printing users, including many long-term users of EnvisionTEC 3D printers. During AMUG Day 1, EnvisionTEC met up with Sean Wise from RepliForm, a metal plating company who has worked on orders from 3D printing service bureau CoKreeate. CoKreeate built their figures on EnvisionTEC 3d printers. RepliForm enjoys working with EnvisionTEC-printed models because these prints display a higher resolution than any other 3D printing system on the market that they have worked with.

- EnvisionTEC’s booth at the show

- Complex geometries created by EnvisionTEC

- AMUG 2014 had many informative sessions for industry members

- The models printed on an EnvisionTEC 3D printer, plated and displayed by Repliform

RepliForm also confirmed that the quality of EnvisionTEC prints translates to an increased level of detail achieved during the plating process. RepliForm showed EnvisionTEC sales rep Alfredo the plated models printed from other machines, but the EnvisionTEC figures had the greatest resolution.

Another highly-detailed sample piece from EnvisionTEC

Last year, Sean Wise’s bust (pictured right, above) was featured at AMUG 2013. Wise demonstrated results of the same print from multiple different machines. During his presentation on electroplating additive manufacturing parts, the EnvisionTEC piece clearly possessed the greatest accuracy and detail.

At AMUG this year, participants were encouraged to be a “band of brothers” in the additive manufacturing community. Keynote speaker Jason Lopes, engineer at Legacy Effects and operator of a Perfactory® 3 printer, gave a presentation called “3D Printing to Reality” on all that can be achieved with 3DP. The collaboration between EnvisionTEC, CoKreeate and RepliForm represents a tight-knit community while giving a taste of what can be achieved when industry members work together.

The SMART Jewelry Show April 5-7 took place in Chicago’s Navy Pier. This multimedia jewelry show is in its sixth year and hosted over 500 exhibitors. The show is successful with jewelers, exhibitors, retailers and visitors attending for business and pleasure all enjoyed this collaborative event.

Bill, our U.S. Jewelry Manager, Shele and Graham from GV Design Canada Inc, and Don and Matt, EnvisionTEC technicians, manned the EnvisionTEC booth. EnvisionTEC brought the Micro HiRes and the new Micro Advantage to the show, both 3D printers which have been developed exclusively for jewelry application, along with the latest material for casting 3D printed objects from EnvisionTEC called EPIC.

EnvisionTEC co-sponsored the yearly SMART Bench Pressure Challenge (along with co-sponsors Stuller and Gemvision) in which four professional jewelers compete to create a custom engagement ring for one lucky set of lovebirds. At this event, EnvisionTEC sponsored the CAD portion of the Challenge. The Bench Pressure Challenge involved two CAD portions, followed by a setting session, engraving session, then a freestyle portion. At the end of the Challenge, the four designers presented their final products to the couple. Don took their models and built them on a P4 Mini XL so the designs would be ready for casting. The winning choice will be cast in platinum donated by Stuller. Stay tuned for a follow-up post from us on the four design entries as well as the winner of the competition.

This weekend EnvisionTEC had the pleasure of participating in two jewelry shows — the Atlanta Jewelry Show at the Cobb Galleria in Atlanta and the MJSA Expo at the New York Hilton. We introduced the Micro Advantage printer in addition to the brand new EPIC material. The Micro Advantage doubles the build envelope of other entry-level 3D printers offered at this time for jewelry applications, with better resolution, while EPIC is an improved casting resin.

At the MJSA show, there were a mix of attendees who were familiar with 3D printing (especially with the recent entrance of consumer-grade machines into the market) and others new to the technology. Micro technician Don focused on educating attendees on 3D printing. He explained the mechanics of EnvisionTEC equipment as well as the benefits of choosing our technology over that of another company. One of our focuses at EnvisionTEC is informing consumers, including small businesses, of what we can do for them.

The Atlanta Jewelry Show saw the attendance of many retail stores, along with numerous independent small businesses. EnvisionTEC sales manager Hratch said he spoke with many mom and pop jewelry stores that want to invest in 3D printing. The lower price point and high build volume of the Micro Advantage caused many of these small stores to revisit the idea of in-house 3D printing. Patrick from Zero Porosity brought casting samples from different printers — his show exhibit helped illustrate Hratch’s role in explaining the differences among different 3D printing technologies.

- Bill speaks with MSJA event attendees at the New York Hilton

- The setup at the Atlanta Jewelry Show

EnvisionTEC presented at this year’s RapidPro event in Veldhoven, the Netherlands. We exhibited our Micro, ULTRA and Perfactory® Standard 3D printers.

We shared a section with EnvisionTEC partners CNC Consult, and Brilliant Technology, along with the Belgian 3D print bureau Tenco Proto, run by client and friend Tom Castermans.

CNC Consult and Brilliant Technology each had their own setups independent of EnvisionTEC to present at RapidPro. Brilliant Technology brought along their professed casting master Rob who introduced models in EC500 resin and their casting results. Both crews were very happy to participate in the show with EnvisionTEC and had a great time.

Also presenting was Tom Castermans, who unveiled several projects 3D printed on EnvisionTEC machines — including an LED visor, a bicycle and a model Miller 91 racecar downsized to 1/43rd on a Perfactory® Aureus. The racecar is a project Castermans started after seeing a Cideas rendering of the same car at a quarter of the size. Read the case study on Tom’s project here.

Also presenting was Tom Castermans, who unveiled several projects 3D printed on EnvisionTEC machines — including an LED visor, a bicycle and a model Miller 91 racecar downsized to 1/43rd on a Perfactory® Aureus. The racecar is a project Castermans started after seeing a Cideas rendering of the same car at a quarter of the size. Read the case study on Tom’s project here.

- Our crew from our Michigan office who answered questions at the show and ran the 3Dent™ with its new speed booster. From left to right: Mike, Marco, Bill, Matt and Hadi

- We had our new high-speed version of the 3Dent on display in the ballroom sponsored by Henry Schein

- We’re on the screen in the Henry Schein ballroom!

- A new EnvisionTEC customer places an order for a 3Dent printer

- Press-E-Cast samples

EnvisionTEC attended this year’s Inhorgenta show in Munich, Germany. This show presents the best of jewelry and watches in addition to show exhibitors related to high-end lifestyle products and services.

“As one of the world’s most important B2B trade shows for jewelry and timepieces, INHORGENTA MUNICH provides the perfect setting for this new project in which we bring experts and forward thinkers together from many different areas like jewelry design, science, graphic design, art, fashion, film, architecture, product design, photography and music,” says Renate Wittgenstein, event manager, on the Inhorgenta website.

“The result will be a long-term platform where experts, forward thinkers and newcomers can move about freely and build bridges to other fields of activity,” Wittgenstein said.

The Inhorgenta show certainly built bridges across industries. The event included a special display called the “Inspiration Lab.” The Inspiration Lab served as a creative space for industry leaders to present lectures, host workshops, and exhibit exciting new products. EnvisionTEC had a host of printers in this exhibit: two each of the Perfactory® 4 Mini, the Perfactory® Aureus and the Perfactory® Micro.

On its website the Inhorgenta refers to this project as a “visionary lifestyle project” with the purpose of marrying different areas — such as design and science — to come up with a new class of ideas. Australian jewelry designer Jordan Askill was featured in the creative think tank. Askill’s Object Render Farm 3D printed several designs on-site while the finished piece was also on display. Askill presented later at the Inhorgenta show, discussing CAD techniques in jewelrymaking.

We had a blast at this year’s Inhorgenta and look forward to building upon relationships that began there.

We had a blast showing off our 3D printing solutions for manufacturing and design spheres, including the ULTRA® 3SP®.

Mike, Rich, Hratch and Andy worked our booth in the Anaheim Convention Center. A lot of attendees came by and it was great to see some familiar clients as well as many engineers designers in the MCAD space. In general the event had a great buzz of activity.

We were happy to make new acquaintances as well! Hratch kept an EnvisionTEC ULTRA 3SP running during the show to build files. Hratch and the team built a handful of parts from a test file, proving the signature EnvisionTEC functionality, accuracy and quality. The ULTRA 3SP employs 3SP® technology (Scan, Spin and Selectively Photocure) which uses a laser diode reflecting off of an orthogonal mirror. Attendees were amazed at this display of laser 3D printing technology, which is different from other typical 3DP processes such as selective laser sintering or fused deposition modeling.

In the niche market, EnvisionTEC is a newcomer to 3D printing. A lot of people came by asking questions about our 3D printing process in general. When EnvisionTEC brings machinery to shows, many people assume that our 3D printers work like others in the industry, but this isn’t so. People were extremely impressed with the surface finish of our models. Routinely almost everybody asked why there weren’t any layer lines and how we could achieve these results.

Our representatives had a great time catching up with old clients and faithful customers, in addition to MCAD companies, model and casting companies, original equipment manufacturers like Boeing and Apple, as well as the occasional jewelry or dental professional.

3D printing has seems like a futuristic idea, but what if all the world’s up-and-coming ideas could be featured in one place? Live from Las Vegas, EnvisionTEC participated in the fabulous 3D printing TechZone at CES 2014. Sales reps Andy, Rich and Mike, along with technician Mike from California, attended the International Consumer Electronics Show this year in the City of Sin and had a blast. Not only did EnvisionTEC have a lot of fun at the CES 2014, but also we were honored to speak with everyone who stopped by our booth (check out our celebrity sighting on Twitter)! Our team is just as excited about 3D printing solutions as you are and we were so glad to see everyone who visited.

Even though 3D printing has been around for a little while now, there are many advancements left to be made. Quality is one such area where 3D machines can advance, and consumer-friendliness is another. EnvisionTEC addressed both issues at CES 2014 with its newest addition to its family of printers, the Perfactory® Micro EDU.

The Perfactory® Micro EDU is our 3D desktop solution for consumers who wish to make professional-grade parts. Whether for educational or functional purposes, the Micro EDU is a great choice for anyone wanting to begin using the full advantages of 3D printing — why not choose one of the best suppliers on the market? The Micro EDU, with out-of-the-box usability and a machine footprint around the size of a coffeemaker, is a great option for those wishing to begin investing in and learning about 3D printing.

ARKETYP 3D’S booth at the 3D PRINTSHOW PARIS exhibiting an ULTRA® 3SP

ARKETYP 3D´s contact details:

ARKETYP 3D´s contact details:

ARKETYP 3D SAS

Intégrateur de systèmes d’impression 3D

11 Bis Allée Notre Dame Des Anges

93340 LE RAINCY

Tél. 01 43 00 05 28

Mob. 06 24 56 96 61

Email. contact@arketyp3d.com

The Smart Jewelry Show Dallas 2013 is just around the corner and EnvisionTEC is proud to be highlighting the latest solutions for jewelry manufacturing. Offering a full complement of 3D printers and materials specifically tailored to help improve your bottom line.

EnvisionTEC is proud to be co-sponsoring the CAD portion of the Smart Show Dallas Bench Challenge on Saturday, August 24. Four CAD gurus will be creating designs based on a single realistic true-to-life scenario with the same design requirements. We will be printing their contest entries on-site to bring them to life right there on the show floor.

Challenge Schedule

CAD I: Saturday, August 24, 10:15 – 12:15

CAD 2: Saturday, August 24, 2pm – 4pm

All-Around 1 – Setting: Sunday, August 25, 10:15am – 12:15pm. (Bring burs, drill bits, etc.)

All-Around 2 – Engraving: Sunday, August 25, 2pm – 4pm

All-Around 3 – Mystery Challenge: Monday, August 26, 10:15am – 12:15pm

Earlier this month, one of EnvisionTEC’s leading distributors, John Burn & Co, was invited to participate in the ceremonies surrounding the renaming of the Royal Academy of Engineering by Prince Philip, Duke of Edinburgh. The newly renovated building will be named for its Senior Fellow HRH The Prince Philip, Duke of Edinburgh – Prince Philip House. Prince Philip formally opened the building on October 16, 2012.

The event was a celebration of engineering innovation and in that vein, John Burn & Co. was asked to showcase their latest 3D printing technology. An EnvisionTEC Perfactory® Micro was on hand as well as a variety of samples of 3D printed samples. Harry Curtis, 3D Printing Sales manager from John Burn & Co and Darrin Dickinson, EnvisionTEC’s Regional Sales Manager (EMEA & APAC) were able to discuss 3D printing with Prince Philip as well as many attending dignitaries and distinguished engineering guests.

Among the samples shown was a question mark, printed on a Perfactory® 3D Printer. Currently this symbol is standing in for the trophy for the Queen Elizabeth Prize for Engineering. This new global engineering prize will recognize and celebrate outstanding advances in engineering that have changed the world and comes with a one million pound prize on top of the prestige of selection and a trophy.

This trophy is part of a second competition, this time for youth who are interested in Science, Engineering, Design, Art and Architecture. A special design application has been created solely for the design of this trophy, which will ultimately be 3D Printed by EnvisionTEC. EnvisionTEC UK will be printing the top entries for prototypes for the judging for the final trophy. The winning design will be presented by HRH Queen Elizabeth to the winner of the Queen Elizabeth Prize for Engineering at Buckingham Palace in May 2013.