Dental Services Group

Our Experience

Dental Services Group is a network of laboratories spread across the continental U.S. Jim Boshoven is the Director of Automated Manufacturing at the group, which invested in EnvisionTEC 3D printing in 2010.

Investing in 3D

Dental Services Group, or DSG, uses 3D printing to make models and patterns for casting. previously these were made via stone and plaster and hand-waxing.

With the advent of digital impression systems, DSG was outsourcing their model work. The company sought to acquire more control over their own production and reduce lead times. Bringing the process in-house would cut down their costs while allowing lab technicians to oversee batches to completion.The lab also considered ObJet and 3D Systems when turning to the market for 3D solutions.

“We felt the cost was worth dealing with EnvisionTEC. We felt the build time was shorter, so our cost per unit was very good,” Boshoven said.

The lab group also considered the material available from EnvisionTEC, which is specially formulated to suit the machine as well as the application.

Integrating EnvisionTEC

DSG had a great experience integrating EnvisionTEC into its workflow. The group initially had an Ultra², an earlier model of the current ULTRA® 3SP®, which had a DLP® projector. The switch to the laser 3SP® technology suited DSG — the group upgraded their machines to the 3Dent™ printer. “There were advantages over the DLP® technology,” said Boshoven, advantages which included auto-calibration and straightforward software. Upon upgrading machines from EnvisionTEC, the new systems were quickly put to work — their production changeover went smoothly with the help of on-site installation and training.

Supporting Smiles

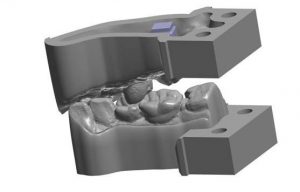

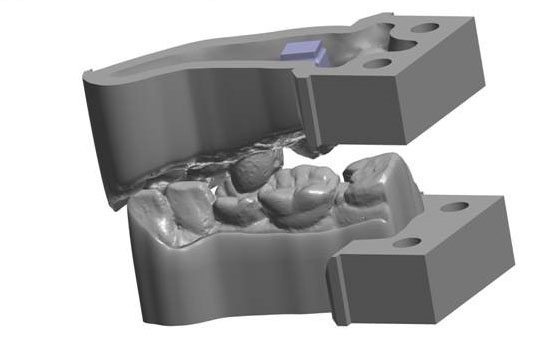

The Dental Services Group have printers at four of their locations — the 3Dent™ and the Perfactory® Micro DDP. DSG uses their 3Dent™ printers for modeling while the Micro DDP is used for wax-ups and lost wax investment casting.

The lab uses data from multiple intraoral scanners, including Trios (the members of Dental Services Group are Trios-certified laboratories), iTero, Carestream, Sirona, and the True Definition Scanner from 3M™. These scans come from dental offices across the country — the lab group uses the data, as it is compatible with EnvisionTEC printers, to build jobs. Whatever technology is used for the scan, Dental Services Group can import the data into its design software, 3Shape, where it can be exported to EnvisionTEC’s RP Perfactory software and then 3D printed.

The lab group uses these scans in a process using both 3D printing and later pressing with a dental material, such as e.max from Ivoclar Vivadent or conventional lost wax casting. The lab prints the models on the 3Dent™, and then using the same files to create and print restorations on the Micro DDP. In order to make sure everything fits as accurately as the original scan, the technician takes the piece back and checks it on the models printed with the 3Dent™.

Economical Dentistry.

“It’s going to grow rapidly. Those savings are significant.”

DSG chose EnvisionTEC because of the smart savings the technology afforded their production process. Today, with the team of EnvisionTEC 3D printers DSG is able to handle all of their current printing needs with room for anticipated growth.

As intraoral scanning technologies improve, Boshoven says, the amount of builds the labs are running will increase. Boshoven places the current amount of dentists using digital scanners to be around 3 percent.

“As that grows to five and then ten percent, and more,” he says, “We will be producing an [increasing] amount of units.” He estimates the excess capacity the group has available to them now will be cut in half in weeks. “Once we start hitting 80 to 90 percent capacity with the machines we have, then thats the time to start looking at ordering additional machines to make sure we have the capacity to grow.”